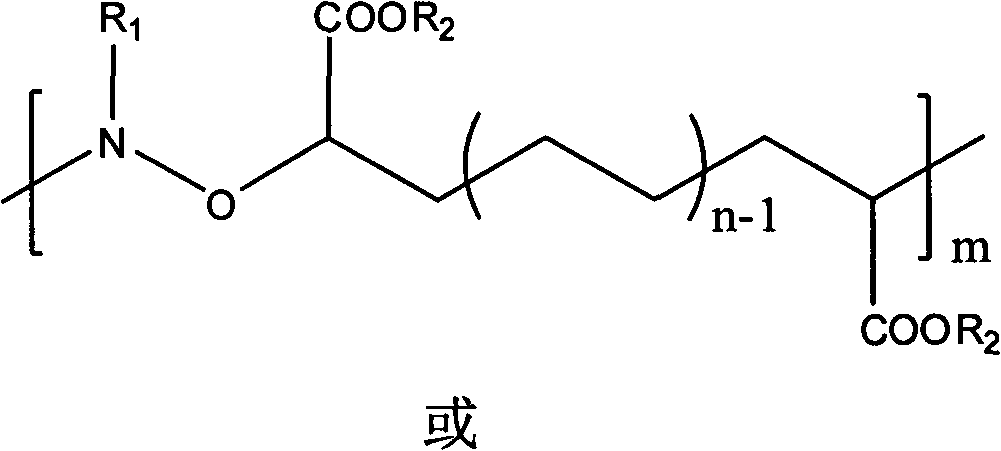

Method for preparing copolymer with multielement alternating structure

A technology of alternating structure and copolymer, which is applied in the field of preparation of copolymers, can solve problems such as side reactions and low molecular weight of polymers, and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

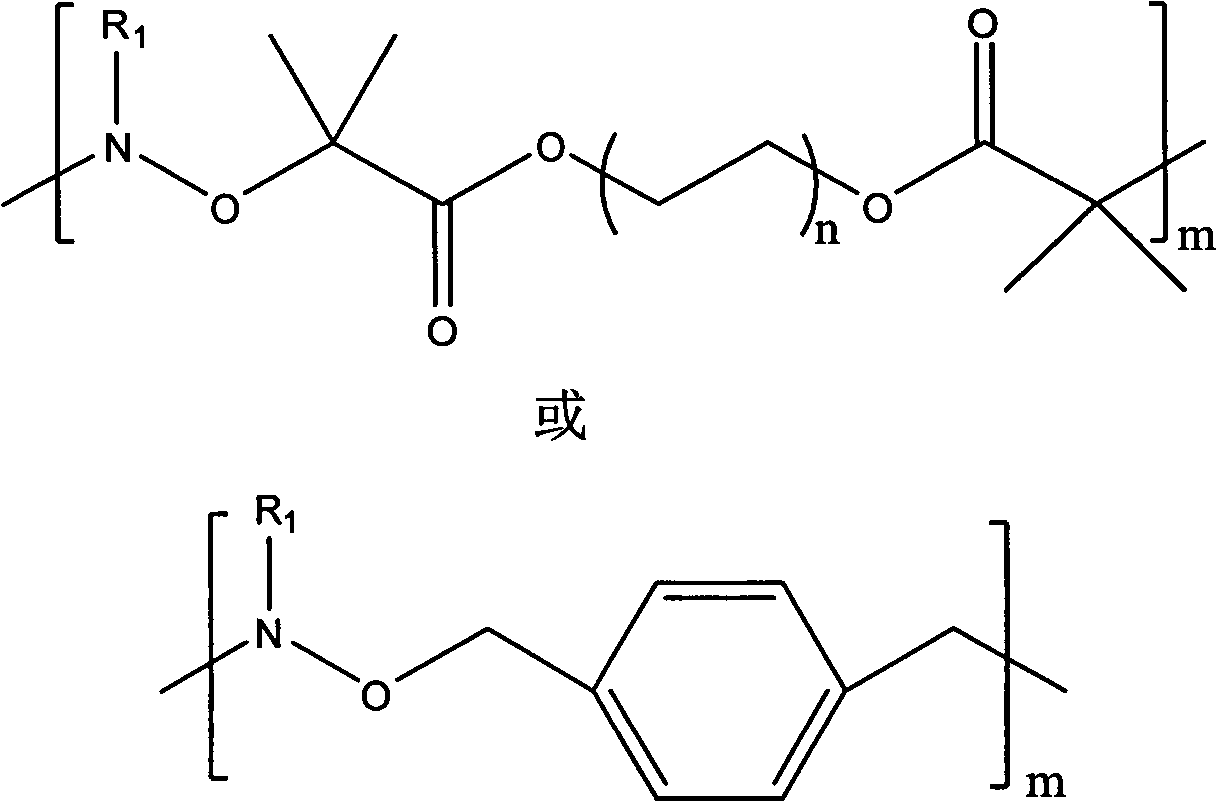

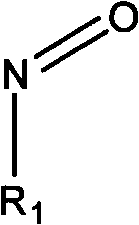

[0022] Embodiment 12, 5-dibromodiethyl adipate (DEDBA) reacts with 2-methyl-2-nitrosopropane (MNP)

[0023] Add 70.4mg Cu powder (1.1mmol), 180mg DEDBA (0.5mmol), 43.5mg MNP (0.5mmol) into the ampoule tube, and replace with nitrogen three times. Add 208 μL (1 mmol) of PMDETA that has been deoxygenated, and THF 1 mL. At 25°C, react for 30 minutes, and quench with liquid nitrogen to terminate the reaction. The polymer was dissolved in acetone, passed through a column of neutral alumina to remove copper, concentrated, and dried under vacuum at 50°C for 24 hours. Gained polymer is tested through gel permeation chromatography (GPC): number average molecular weight (M n ) = 8360 g / mol, molecular weight distribution index (PDI) = 2.35.

Embodiment 22

[0024] Example 22, 7-dibromosuberate dimethyl (DMDBO) reacts with 2-methyl-2-nitrosopropane (MNP)

[0025] Synthesis of dimethyl 2,7-dibromosuberate (DMDBO): Add 5.23g (0.03mol) of suberic acid and 5.4mL (0.075mol) of thionyl chloride into a 25mL Schlenk bottle and heat to 80°C , reacted for 1.5 hours. The heating was stopped, and the remaining thionyl chloride was removed from the Schlenk bottle. The Schlenk bottle was heated to 85°C, and 3.9mL (0.076mmol) of liquid bromine (Br 2 ) slowly added to the Schlenk bottle several times (0.5 mL each time), and the addition was completed within 6 hours. Stirring was continued at 85°C for 3 hours. The hot reaction solution was added dropwise into 50 mL of ice-cooled anhydrous methanol solution, raised to room temperature, and stirred overnight. The methanol solution was poured into deionized water at 0 °C to obtain a yellow turbid liquid. With 5×30mL CH 2 Cl 2 Extract and combine the organic layers. The organic layer was washe...

Embodiment 3-8

[0027] Example 3-8 Reaction of 2,13-dibromotetradecanedioic acid dimethyl ester (DMDBT) with 2-methyl-2-nitrosopropane (MNP)

[0028] Synthesis of 2,13-dibromotetradecanedioic acid dimethyl ester (DMDBT): 5.16g (0.02mol) tetradecanedioic acid, 4.3mL (0.06mol) thionyl chloride were added to a 25mL Schlenk bottle, Heated to 80°C and reacted for 1.5 hours. The heating was stopped, and the remaining thionyl chloride was removed from the Schlenk bottle. The Schlenk bottle was heated to 85°C, and 2.6mL (0.05mmol) of Br 2 Slowly add to the Schlenk bottle several times (0.5 mL each time) and complete the addition within 4 hours. Stirring was continued at 85°C for 3 hours. The hot reaction solution was added dropwise into 40 mL of anhydrous methanol solution cooled in an ice bath, raised to room temperature, and stirred overnight. The methanol solution was poured into 80 mL of deionized water at 0 °C to obtain a yellow turbid liquid. With 5×30mL CH 2 Cl 2 Extract and combine the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com