Slow-release plastic expanding agent for cement-based binding material and preparation method of slow-release plastic expanding agent

A technology of plastic expansion agent and cementitious material, applied in the chemical field of cement-based cementitious material, can solve the problems of inability to compensate for chemical shrinkage, self-shrinkage and other shrinkage problems, unfavorable development of concrete strength and durability, uneven gas generation, etc. Achieve the effect of maintaining volume stability, improving the ability to resist segregation and bleeding, and improving flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) 10 parts of calcium stearate and 5 parts of diethylene glycol, 5 parts of isobutyl methacrylate and 2 parts of silicone oil are mixed uniformly with the solid and liquid components in parts by mass;

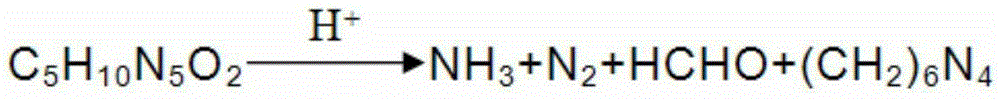

[0048] 2) Add 45 parts of azodicarbonamide, 33 parts of N,N'-dinitrosopentamethylenetetramine and the pre-mixed foaming aid and foam stabilizer in step 1) to a small ball mill of solid components;

[0049] 3) Add the liquid mixing component of step 1) in the grinding process of step 2), and after the two components are ground evenly, control the particle size to be less than 80 μm, that is, to obtain the plastic expansion of slow-release cement-based cementitious material agent.

[0050]The plastic expansion agent for slow-release cement-based cementitious materials prepared in this example is mixed into C40 concrete at 0.2‰ of the cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is 0%, the 28d free expansion rate reaches 0...

Embodiment 2

[0052] 1) Prepare 10 parts of zinc stearate and 10 parts of borax in mass parts, and mix the solid components and liquid components in 6 parts of silicone oil evenly;

[0053] 2) Add 34 parts of azodicarbonamide, 40 parts of N,N'-dinitrosopentamethylenetetramine and the pre-mixed foaming aid and foam stabilizer in step 1) to a small ball mill of solid components;

[0054] 3) Add the liquid mixing component of step 1) in the grinding process of step 2), and after the two components are ground evenly, control the particle size to be less than 80 μm, that is, to obtain the plastic expansion of slow-release cement-based cementitious material agent.

[0055] The plastic expansion agent for slow-release cement-based cementitious materials prepared in this example is mixed into C30 concrete at 0.1‰ of the cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is 0.01%, the 28d free expansion rate reaches 0.05%, and the 28-day compressive stren...

Embodiment 3

[0057] 1) the mass parts are 10 parts of zinc stearate and 5 parts of glycerin, the solid component and the liquid component in 5 parts of isobutyl methacrylate and 2 parts of silicone oil are mixed uniformly respectively;

[0058] 2) Add 40 parts of azodicarbonamide, 35 parts of N,N'-dinitrosopentamethylenetetramine and the pre-mixed foaming aid and foam stabilizer in step 1) to a small ball mill of solid components;

[0059] 3) Add the liquid mixing component of step 1) in the grinding process of step 2), and after the two components are ground evenly, control the particle size to be less than 80 μm, that is, to obtain the plastic expansion of slow-release cement-based cementitious material agent.

[0060] The plastic expansion agent for slow-release cement-based cementitious materials prepared in this example is mixed into the C80 pipe pile concrete at 0.1‰ of the cementitious materials in ordinary concrete. The early plastic shrinkage rate of the concrete is 0%, the 28d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com