Diaphragm and method for preparing composite electrode couple by utilizing diaphragm

A separator and adhesive technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increasing the internal resistance of the battery, reducing the porosity of the separator, and entering the porous separator to block the pores, so as to reduce the possibility of being blocked, The effect of avoiding the possibility of direct contact forming an internal short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

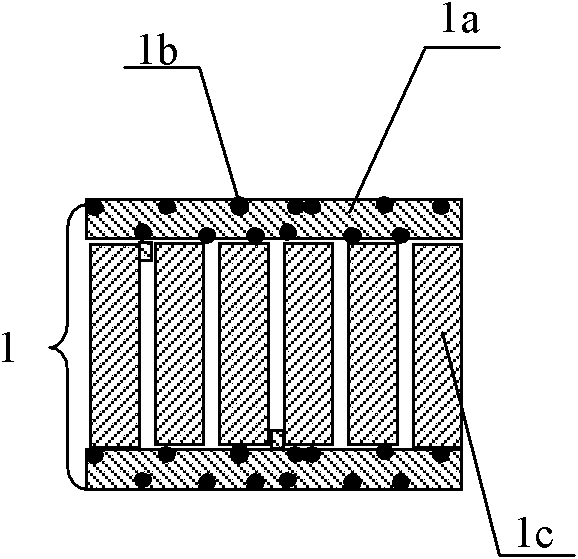

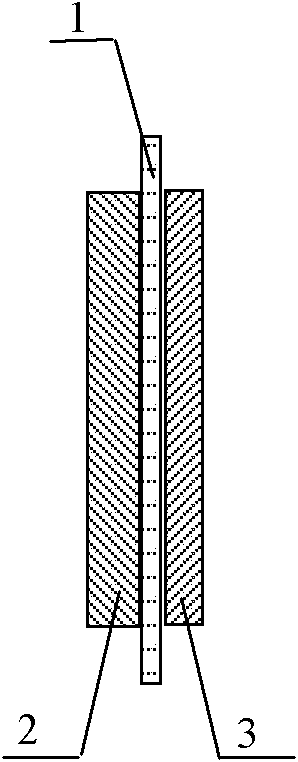

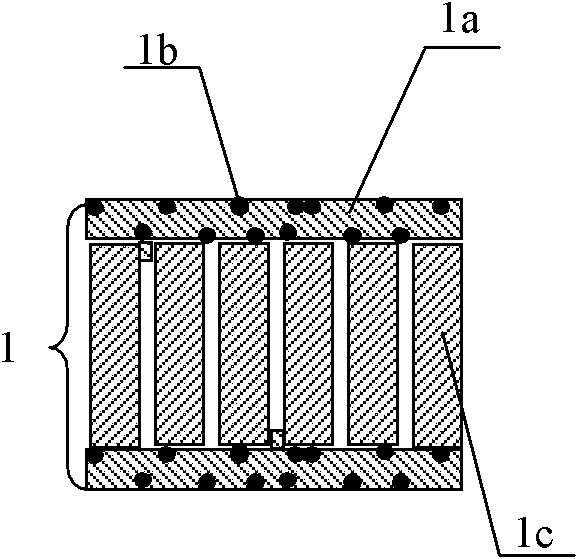

[0020] Preparation of diaphragm: PVDF (polyvinylidene fluoride), 4,4'-oxidized bisbenzenesulfonyl hydrazide (composed of polyvinylidene fluoride by mass percentage: 4,4'-oxidized bisbenzenesulfonyl hydrazide=10:90 ) mixed in NMP (N-methylpyrrolidone) to obtain a slurry, which is evenly coated on the surface coated with SiO 2 One side of the non-woven porous matrix of the inorganic nanoparticle layer is dried at 60-110°C; the same slurry is evenly coated on the other side of the porous matrix, and dried at 60-110°C to obtain a diaphragm. Mix PVDF adhesive, carbon black and modified lithium manganate (adhesive by mass percentage: carbon black: lithium manganate = 8:7:85) in NMP (N-methylpyrrolidone), and mix thoroughly to make a positive electrode slurry. Coat the slurry on one side of the above separator, and dry it at 60-110°C; mix PVDF, lithium titanate and carbon black (composition by mass percentage: lithium titanate:carbon black:adhesive=90:3:7) Mix it in NMP, mix thorou...

Embodiment 2

[0022] Preparation of diaphragm: SBR (styrene-butadiene rubber) and CMC (sodium carboxymethyl cellulose), 4,4'-oxidized bisbenzenesulfonyl hydrazide (composed by mass percentage as SBR: CMC: 4,4'-oxidized bis-benzenesulfonyl hydrazide) Benzenesulfonyl hydrazide=5:3:92) is mixed in deionized water to obtain a slurry, and the slurry is evenly coated on the surface coated with SiO 2 One side of the non-woven porous matrix of the inorganic nanoparticle layer is dried at 60-110°C; the same slurry is evenly coated on the other side of the porous matrix, and dried at 60-110°C to obtain a diaphragm. Mix SBR and CMC, carbon black and modified lithium manganate (composed of SBR and CMC mixed adhesive by mass percentage: carbon black: lithium manganate = 8: 7: 85) in deionized water, fully mix to make positive electrode slurry material. This slurry is coated on one side of above-mentioned septum, at 60~110 ℃ of oven dry; SBR and CMC, artificial graphite and carbon black (by mass percent...

Embodiment 3

[0024] Preparation of diaphragm: polyvinyl chloride and benzenesulfonyl hydrazide (composed of polyvinyl chloride: benzenesulfonyl hydrazide = 9: 91 by mass percentage) are mixed in DMSO (dimethyl sulfoxide) to obtain a slurry, and the slurry The slurry is evenly coated on one side of a polyolefin porous substrate with a thickness of 25 microns, and dried at 60-80°C; then the same slurry is evenly coated on the other side of the porous substrate, and dried at 60-80°C to prepare Got diaphragm. Mix PVDF adhesive, carbon black and modified lithium manganate (adhesive by mass percentage: carbon black: lithium manganate = 8:7:85) in NMP (N-methylpyrrolidone), and mix thoroughly to make a positive electrode slurry. Coat the slurry on one side of the above diaphragm and dry at 60-80°C; mix PVDF, artificial graphite and carbon black (composed of artificial graphite:carbon black:adhesive=90:3:7 by mass percentage) in In NMP (N-methylpyrrolidone), mix well to make a negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com