Method for preparing 3-methyl-4-nitrobenzoic acid by oxidizing with nitric acid

A technology of oxidation of nitrobenzoic acid and nitric acid, which is applied in the field of synthesis of fine chemical products, can solve the problems of expensive catalysts and oxidants, high production costs, and difficult processing, and achieves improved production operation safety, low manufacturing costs, The effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a method for preparing 3-methyl-4-nitrobenzoic acid by oxidation of nitric acid. The preparation of 3-methyl-4-nitrobenzoic acid uses dilute nitric acid as an oxidant and 2,4-dimethylnitrobenzene as a raw material, and is prepared in a common reaction kettle.

[0019] The specific operation steps of this embodiment are as follows:

[0020] Step 1, feeding. Put 2,4-dimethylnitrobenzene and dilute nitric acid with a concentration of 30-65% into the reactor through the elevated tank, and the molar ratio of 2,4-dimethylnitrobenzene to dilute nitric acid is 1:5.5 ~8.0.

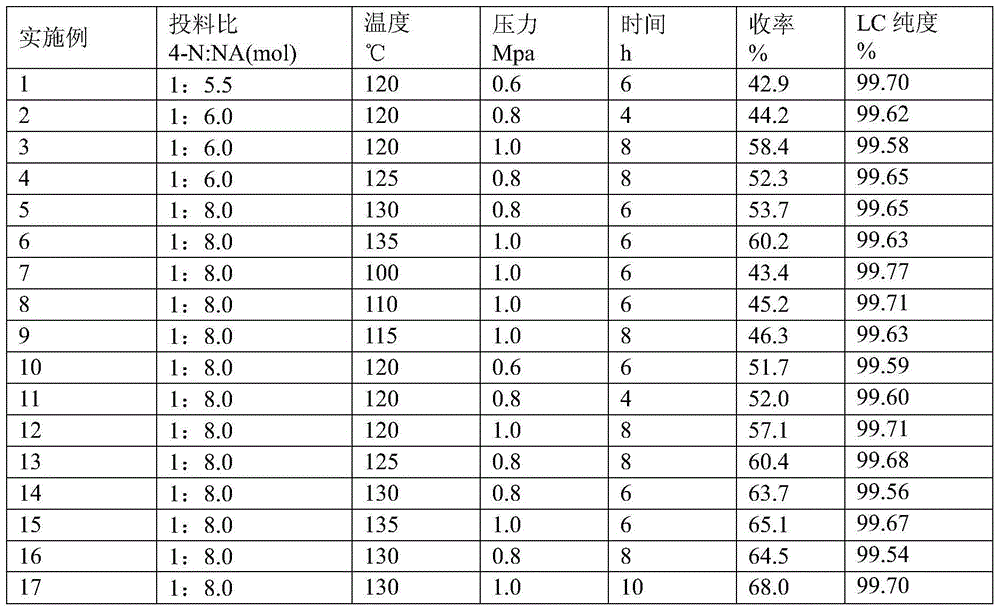

[0021] The specific parameters of step 1 in each embodiment of table 1

[0022] Example

Dilute nitric acid concentration%

The ratio of 2,4-dimethylnitrobenzene to dilute nitric acid

1

30

1:5.5

2

30

1:6

3

30

1:6

4

30

1:6

5

30

1:8

6

45

1:8

7

45

1:8

8

45

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com