Nano silicon dioxide for rubber reinforcement and preparation method thereof

A nano-silicon dioxide and carbon dioxide technology, applied in the field of rubber reinforcing additives and rubber additives, can solve the problems of solid materials unable to pass through microchannels, continuous production, and low gas utilization, achieving good dispersion and low wear. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

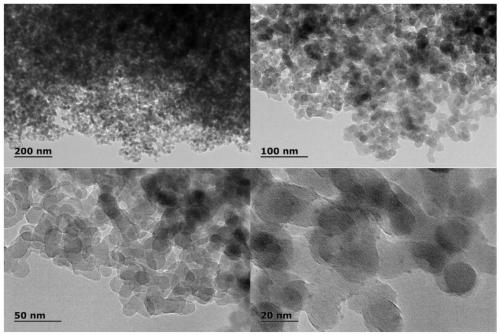

Image

Examples

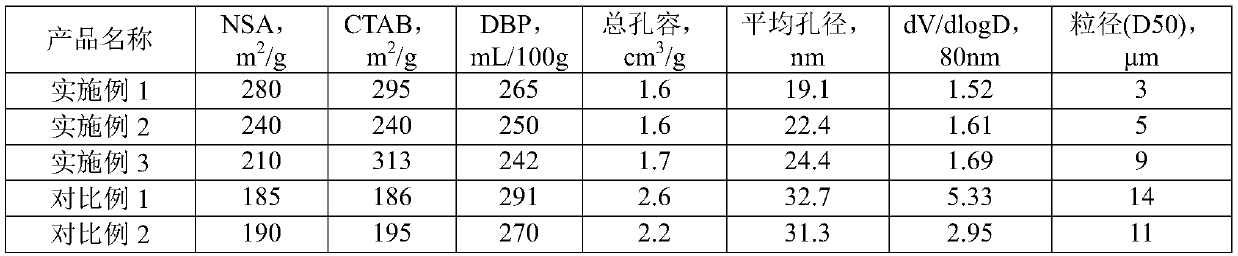

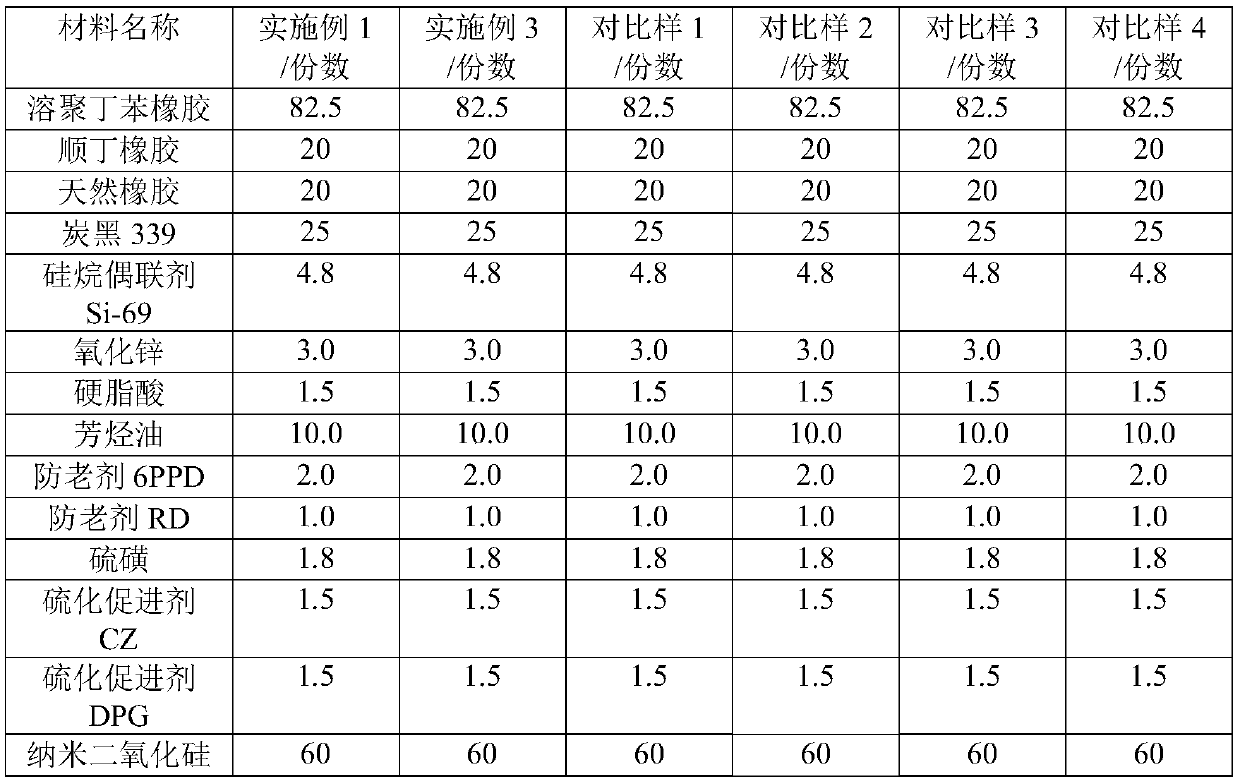

Embodiment 1

[0044] A kind of preparation method that is used for rubber reinforcing additive described in this embodiment, comprises the steps:

[0045] 1) Install a 1μm dispersion film on the stirring blade of the reactor.

[0046] 2) Take the first grade sodium silicate solution with a modulus of 3.4 and a commercially available Baume degree of 38, and prepare 120L of dilute water glass with a Baume degree of 22;

[0047] 3) Pump the sodium silicate solution in step 1) into a 150L reactor, turn on the stirring and heat the liquid, set the stirring speed to 12Hz, and the temperature to 70°C;

[0048] 4) When the temperature reaches 70°C, open the carbon dioxide valve, the gas enters the solution through the hollow shaft of the stirring paddle and the membrane dispersion paddle, and the carbon dioxide gas with a concentration of 100wt% is introduced, and the stirring speed is increased to 20Hz at the same time;

[0049] 5) After injecting carbon dioxide gas for 28 minutes, stop the venti...

Embodiment 2

[0056] A kind of preparation method that is used for rubber reinforcing additive described in this embodiment, comprises the steps:

[0057] 1) Install a 5μm dispersion film on the stirring blade of the reactor.

[0058] 2) Take the first grade sodium silicate solution with a modulus of 3.2 and a commercially available Baume degree of 38, and prepare 120L of dilute water glass with a Baume degree of 25;

[0059] 3) Pump the sodium silicate solution in step 2) into a 150L reactor, turn on the stirring and heat the liquid, set the stirring speed to 12Hz, and the temperature to 70°C;

[0060] 4) When the temperature reaches 70°C, open the carbon dioxide valve, the gas enters the solution through the hollow shaft of the stirring paddle and the membrane dispersion paddle, and the carbon dioxide gas with a concentration of 100wt% is introduced, and the stirring speed is increased to 20Hz at the same time;

[0061] 5) After injecting carbon dioxide gas for 20 minutes, stop the venti...

Embodiment 3

[0068] A kind of preparation method that is used for rubber reinforcing additive described in this embodiment, comprises the steps:

[0069] 1) Install a 20μm dispersion film on the stirring blade of the reactor.

[0070] 2) Take the first grade sodium silicate solution with a modulus of 3.3 and a commercially available Baume degree of about 38, and prepare 120L of dilute water glass with a Baume degree of 16;

[0071] 3) Pump the sodium silicate solution in step 2) into a 150L reactor, turn on the stirring and heat the liquid, set the stirring speed to 12Hz, and the temperature to 70°C;

[0072] 4) When the temperature reaches 70°C, open the carbon dioxide valve, the gas enters the solution through the hollow shaft of the stirring paddle and the membrane dispersion paddle, and the carbon dioxide gas with a concentration of 100wt% is introduced, and the stirring speed is increased to 20Hz at the same time;

[0073] 5) After injecting carbon dioxide gas for 20 minutes, stop th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com