Active atom beam spraying DC discharging process for preparing nano carbon nitride film

A DC discharge, nano-film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

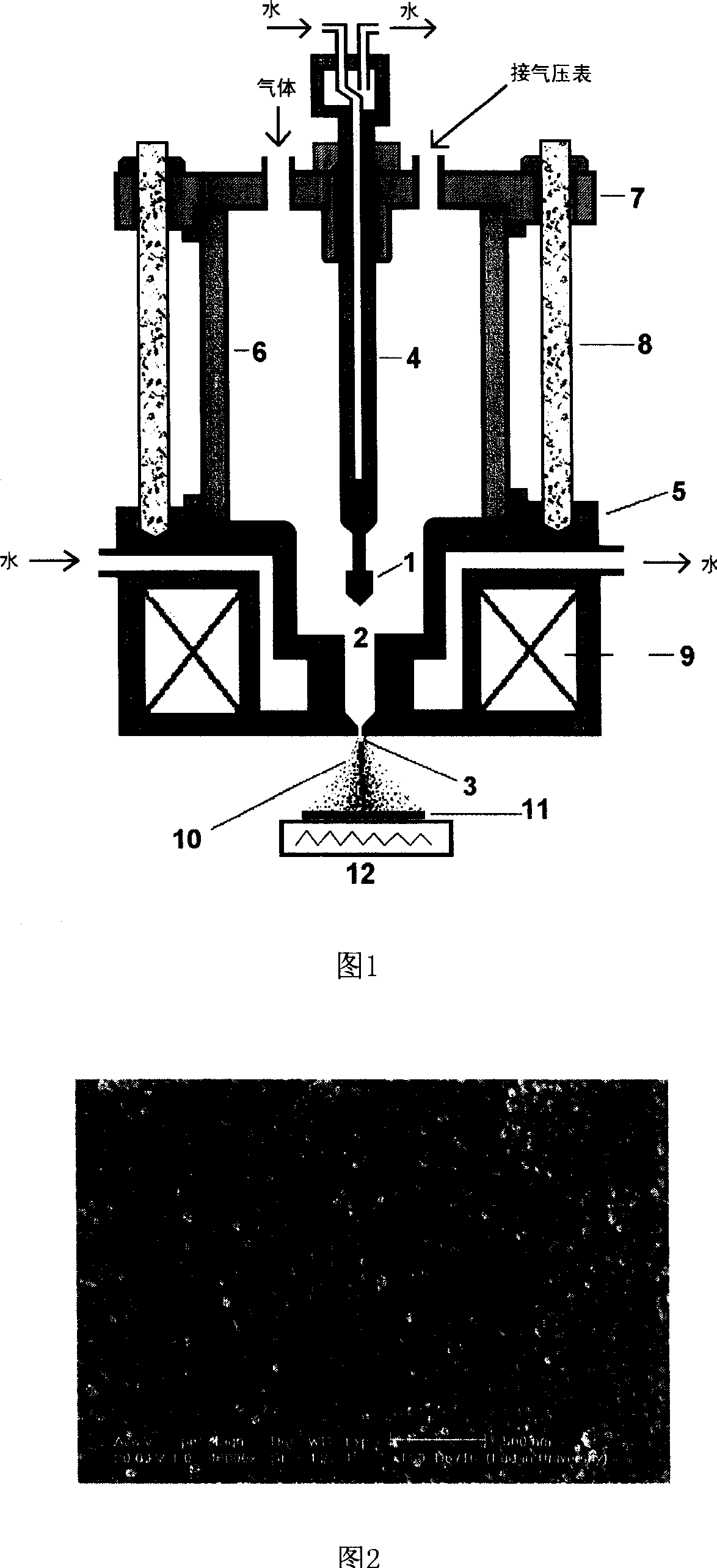

Method used

Image

Examples

Embodiment 1

[0040] The parameters of the preparation process are as follows:

[0041] Cathode-anode spacing: 0.6 cm, anode lead-out hole size: length 0.12 cm, diameter 0.2 cm, deposition chamber background vacuum: 10 -7 Torr, atomic beam source pressure: 30 Torr, deposition chamber pressure: 3 Torr, discharge current: 200 mA, discharge voltage: 150 V, Co / Ni transition layer thickness: 50 nm, methane / nitrogen: 1 / 50 deposition rate: 0.07 microns / min.

[0042] Composition structure index of synthetic carbon nitride nano film:

[0043] The film is composed of uniform and dense spherical grains;

[0044] The average grain size is 30-50 nanometers;

[0045] β-C in film 3 N 4 and graphite phase C 3 N 4 Composition ratio 4.5:1;

[0046] The composition of graphite and amorphous carbon in the film is less than 5%.

Embodiment 2

[0048] The parameters of the preparation process are as follows:

[0049] Cathode-anode spacing: 0.6 cm, anode lead-out hole size: length 0.12 cm, diameter 0.2 cm, deposition chamber background vacuum: 10 -7 Torr, atomic beam source pressure: 30 Torr, deposition chamber pressure: 3 Torr, discharge current: 200 mA, discharge voltage: 150 V, Co / Ni transition layer thickness: 50 nm, methane / nitrogen: 1 / 10, deposition rate : 0.11 μm / min.

[0050] Composition structure index of synthetic carbon nitride nano film:

[0051] The film is composed of uniform and dense spherical grains;

[0052] The average grain size is 30-50 nanometers;

[0053] β-C in film 3 N 4 and graphite phase C 3 N 4 The composition ratio is 2:1;

[0054] The composition of graphite and amorphous carbon in the film is about 10%.

Embodiment 3

[0056] Cathode-anode spacing: 0.6 cm, anode lead-out hole size: length 0.12 cm, diameter 0.2 cm, deposition chamber background vacuum: 10 -7 Torr, atomic beam source pressure: 30 Torr, deposition chamber pressure: 3 Torr, discharge current: 200 mA, discharge voltage: 150 V, Co / Ni transition layer thickness: 25 nm, methane / nitrogen: 1 / 50, deposition rate : 0.05 μm / min.

[0057] Composition structure index of synthetic carbon nitride nano film:

[0058] The film is composed of uniform and dense spherical grains;

[0059] The average grain size is 20-30 nanometers;

[0060] β-C in film 3 N 4 and graphite phase C 3 N 4 The composition ratio is 3:1;

[0061] The composition of graphite and amorphous carbon in the film is less than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com