Main body film forming resin for photoresist and its preparation method and uses

A film-forming resin and photoresist technology, which is applied to the main film-forming resin for photoresist and its preparation and application fields, can solve the problems of low glass transition temperature, insufficient heat resistance and the like, and achieves high resolution, Good adhesion and no deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

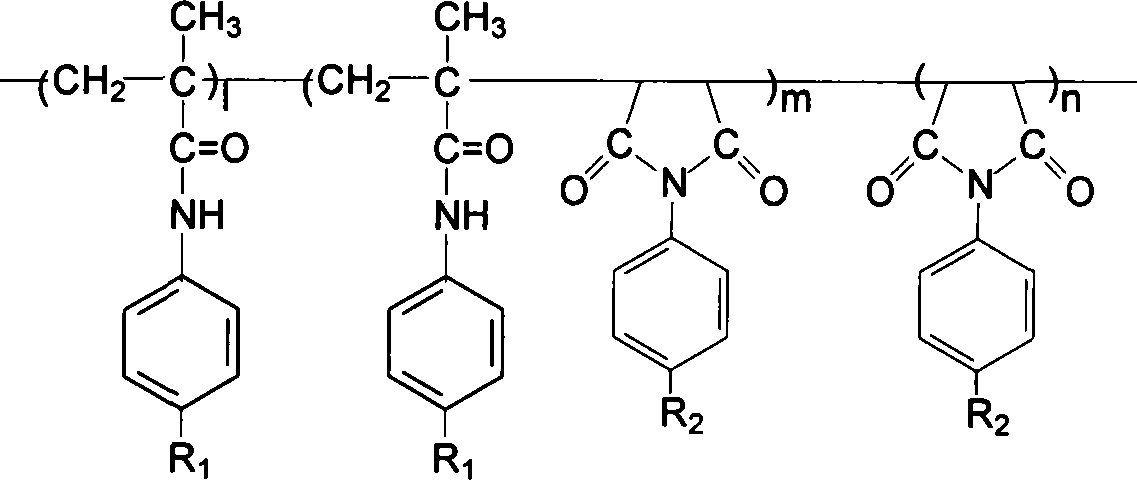

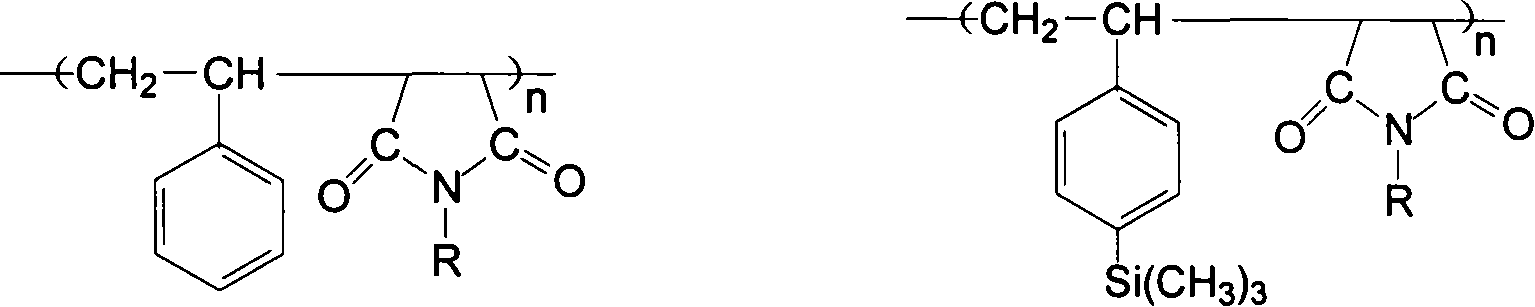

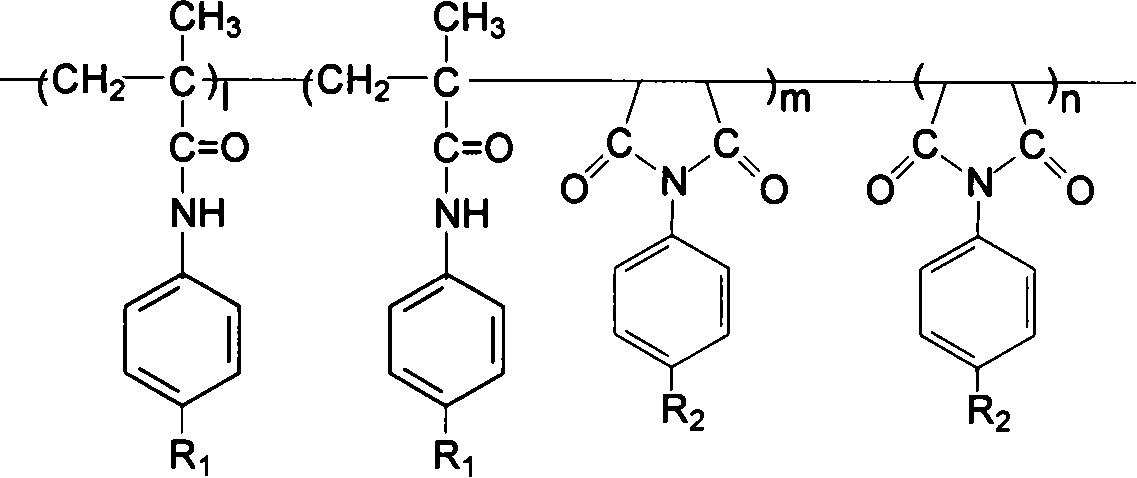

Method used

Image

Examples

example 1

[0027] Example 1: Dissolve monomer N-phenylmethacrylamide and monomer N-phenylmaleimide in dioxane (W / W: 1 / 10) at a molar ratio of 1:1, Make a homogeneous solution, add 1% AIBN of the total weight of monomers as a free radical polymerization initiator, vacuumize to remove oxygen, and protect it with nitrogen, at a constant temperature of 65 ° C, statically polymerize for 24 hours, and then slowly pour it into the precipitant ether , precipitated polymer precipitate, suction filtration, vacuum drying to obtain a crude product. The crude product was redissolved in dioxane (W / W: 1 / 10), and then slowly poured into diethyl ether (9 times the volume of dioxane used), precipitated, suction filtered, 65°C Vacuum drying was repeated three times to obtain a purified copolymer resin.

[0028] After the copolymer resin is compounded with diazonaphthoquinone sulfonyl chloride, benzophenone and cyclohexanone in proportion (W / W, 5:1.6:2:100), it can be filtered through an ultrafiltration me...

example 2

[0029] Example 2: The monomer N-(p-acetoxyphenyl) methacrylamide and the monomer N-(p-hydroxyphenyl) maleimide are dissolved in DMSO (W / W: 1 / 13), make a homogeneous solution, add 10% of the total weight of the monomer BPO as a free radical polymerization initiator, vacuumize and remove oxygen, and protect with nitrogen, and stir and polymerize for 48 hours at a constant temperature of 70°C , and then slowly poured into precipitant water, precipitated polymer precipitate, suction filtration, vacuum drying to obtain crude product. The crude product was re-dissolved in DMSO (W / W: 1 / 13), then slowly poured into water (5 times the volume of DMSO), filtered with suction, vacuum-dried at 65°C, and repeated three times to obtain a purified copolymer resin.

[0030] After compounding the copolymer resin with diazonaphthoquinone sulfonyl chloride, benzophenone and ethylene glycol monoethyl ether in proportion (W / W, 20:8:5:100), it can be filtered through ultrafiltration membrane Make...

example 3

[0031] Example 3: The monomer N-(p-acetoxyphenyl) methacrylamide and the monomer N-(p-hydroxyphenyl) maleimide are dissolved in DMF (W / W: 1 / 15) to make a homogeneous solution, add 19% of the total weight of the monomer BPO as a free radical polymerization initiator, vacuumize and remove oxygen, and protect with nitrogen, and stir and polymerize for 72 hours at a constant temperature of 75°C , and then slowly poured into precipitant water, precipitated polymer precipitate, suction filtration, vacuum drying to obtain crude product. The crude product was redissolved in DMF (W / W: 1 / 15), then slowly poured into water (1 times the volume of DMSO), filtered with suction, dried in vacuum at 65°C, and repeated three times to obtain a purified copolymer resin.

[0032] After compounding the copolymer resin with diazonaphthoquinone sulfonyl chloride, benzophenone and ethylene glycol monoethyl ether in proportion (W / W, 40:12:8:100), it can be filtered through ultrafiltration membrane M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com