Photosensitive composition, photosensitive film, photosensitive layered body, permanent pattern forming method and printed circuit board

A technology of photosensitive composition and photosensitive layer, which is applied in printed circuit, printed circuit manufacturing, microlithography exposure equipment, etc., can solve the problems of no preservation and reduction of preservation, and achieve plating resistance and preservation Excellent, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

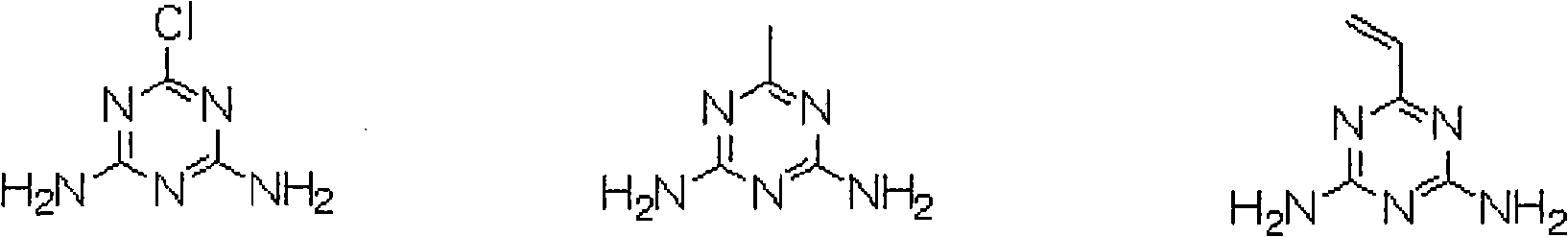

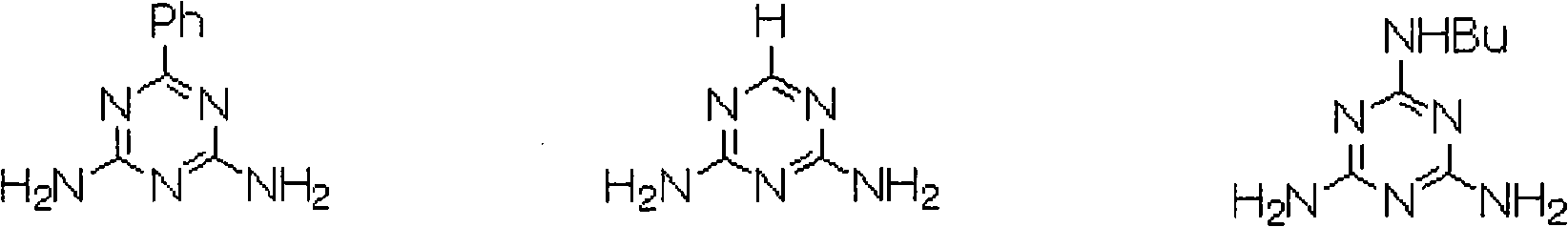

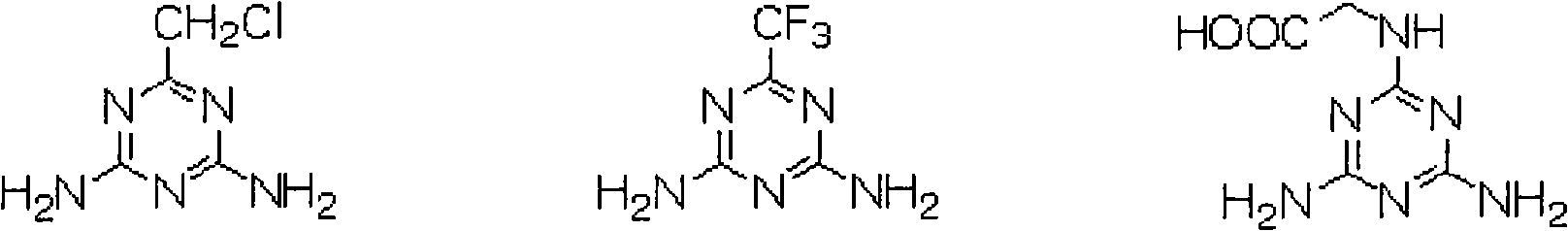

Method used

Image

Examples

Embodiment 1

[0473] -Manufacture of photosensitive film-

[0474] On a polyethylene terephthalate film (manufactured by Toray Co., Ltd., 16FB50) with a thickness of 16 μm as a support, a photosensitive composition solution having the following composition was applied and dried. A photosensitive layer with a thickness of 30 μm was formed on the support. A 20-μm-thick polypropylene film (Alphane E-200, manufactured by Oji Special Paper Co., Ltd.) was laminated as a protective layer on the photosensitive layer to produce a photosensitive film.

[0475] Composition of

[0476] The solution of the binder shown in the following formula B-1... 37.2 parts by mass

[0477] A-DPH (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., hereinafter referred to as polymerizable compound “J-1”)………………………………………………… 9.15 parts by mass

[0478] Compound represented by the following formula K-1 (manufactured by Daito Chemical Co., Ltd.) ... 0.63 parts by mass

[0479] DETX (manufactured by Nippon Ka...

Synthetic example 1

[0489] Synthesis of Adhesive B-1

[0490] 90.6 g of 1-methoxy-2-propanol was placed in a 1000 mL three-necked flask, and heated to 90° C. under a nitrogen stream. 105.8 g of benzyl methacrylate, 120.6 g of methacrylic acid in 156 g of 1-methoxy-2-propanol, and 7.24 g of V-601 (manufactured by Wako Pure Chemical Industries) were added dropwise thereto over 3 hours. - 50 g solution in methoxy-2-propanol. After the dropping was terminated, it was heated for an additional hour to make it react. Next, a solution of 20 g of 1-methoxy-2-propanol in 2.00 g of V-601 (manufactured by Wako Pure Chemical Industries, Ltd.) was added dropwise over 1 hour. After the dropwise addition was terminated, the mixture was heated for another 3 hours to make it react, and then the heating was stopped to obtain a copolymer of benzyl methacrylate / methacrylic acid (30 / 70 mol% ratio).

[0491]Next, 105.2 g of glycidyl methacrylate and 20 g of 1-methoxy-2-propanol were added to the dropping funnel, and...

Embodiment 2

[0528] Except that the addition amount of the compound represented by the above formula M-1 in the photosensitive composition solution was changed from 1 mass part to 2 mass parts, a laminated body and a permanent pattern were produced in the same manner as in Example 1, and in the same manner as in Example 1. The protective film detachability, sensitivity, developability (shortest developing time), survivability, and resistance to electroless gold plating were evaluated in a systematic manner. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com