Engraved intaglio plate polishing equipment and polishing process

A technology of engraving gravure and equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of low polishing quality, poor polishing method safety, and low polishing efficiency, so as to improve polishing quality, Strong anti-side load ability, ensuring uniform and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

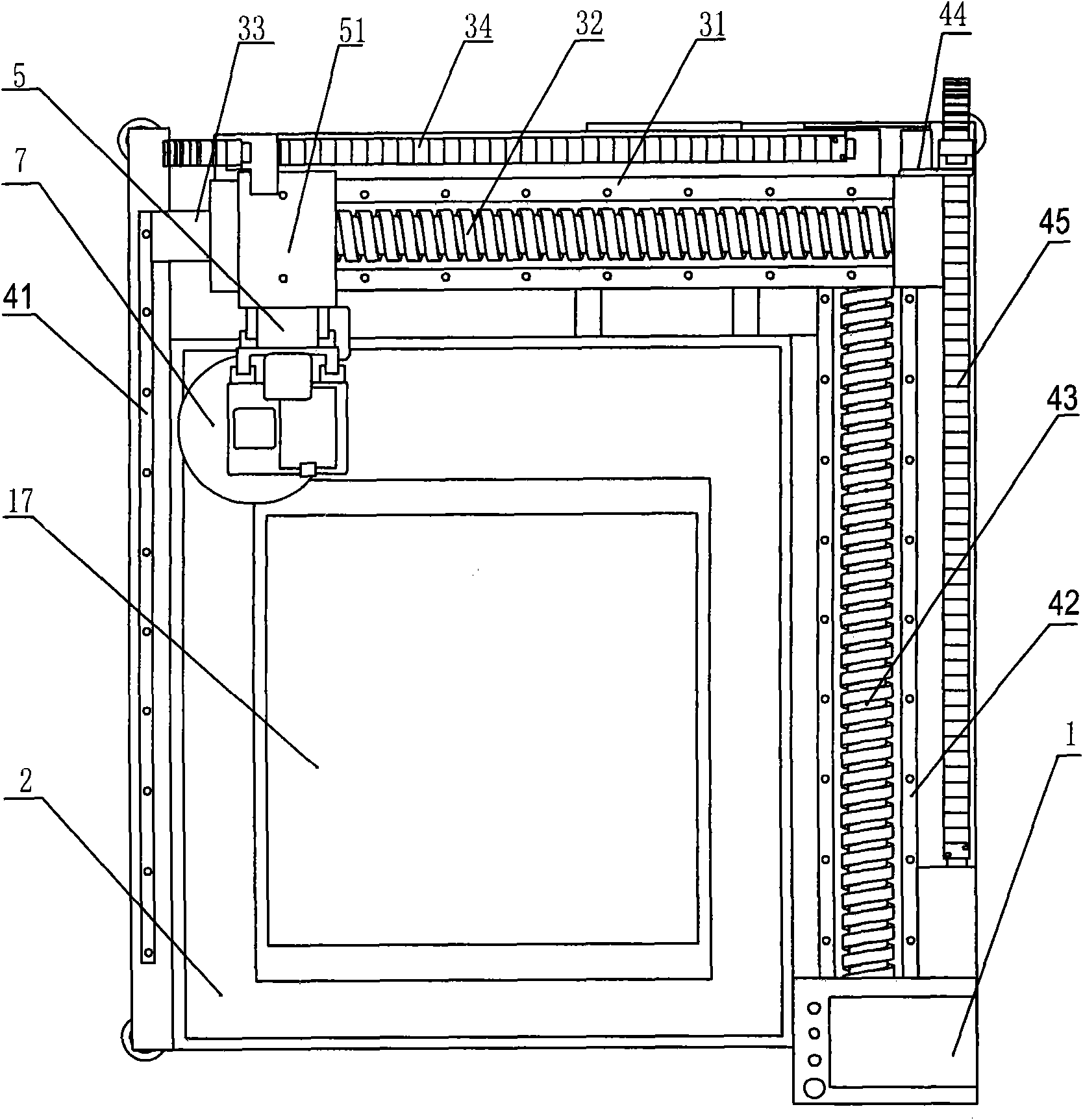

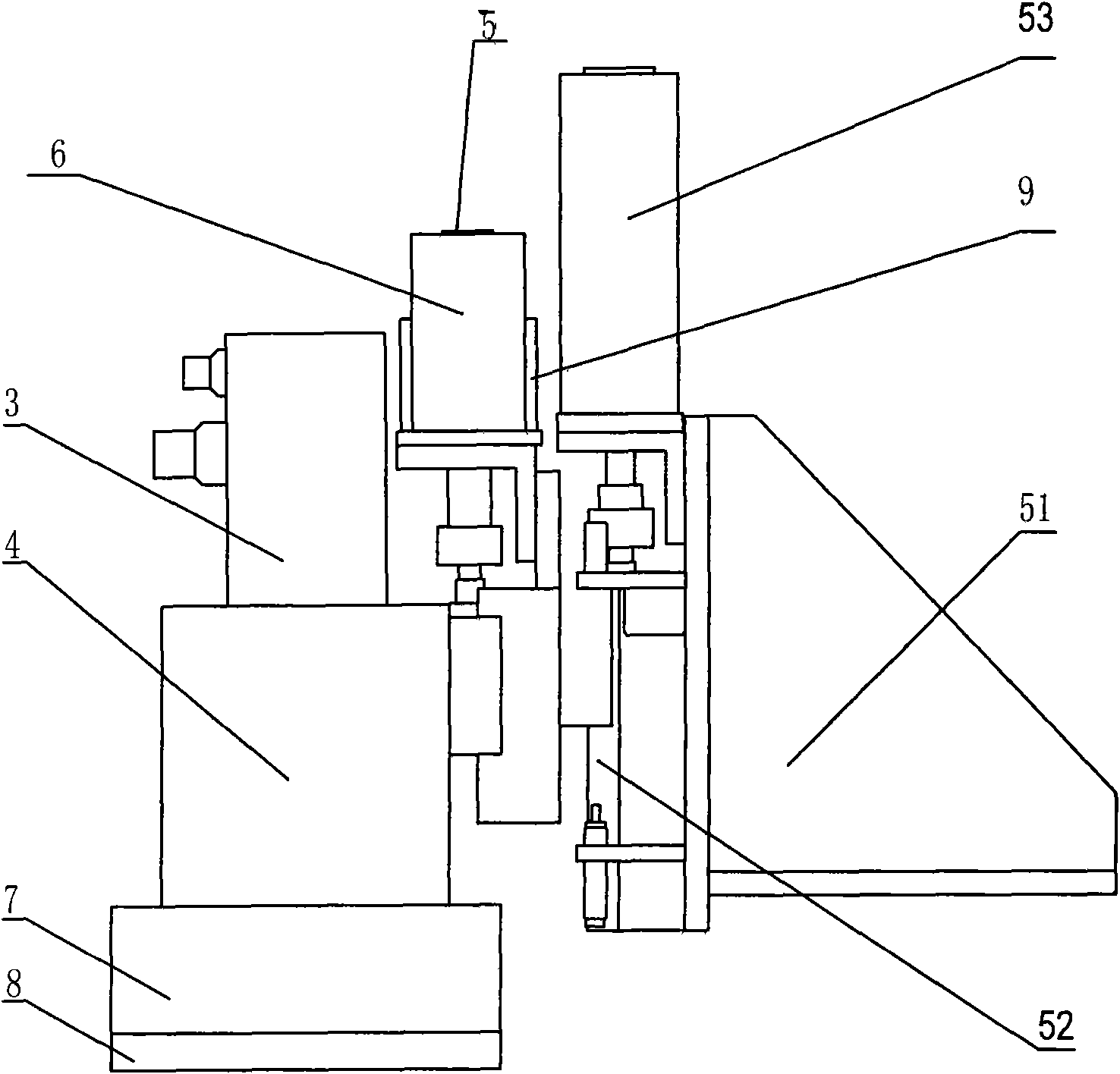

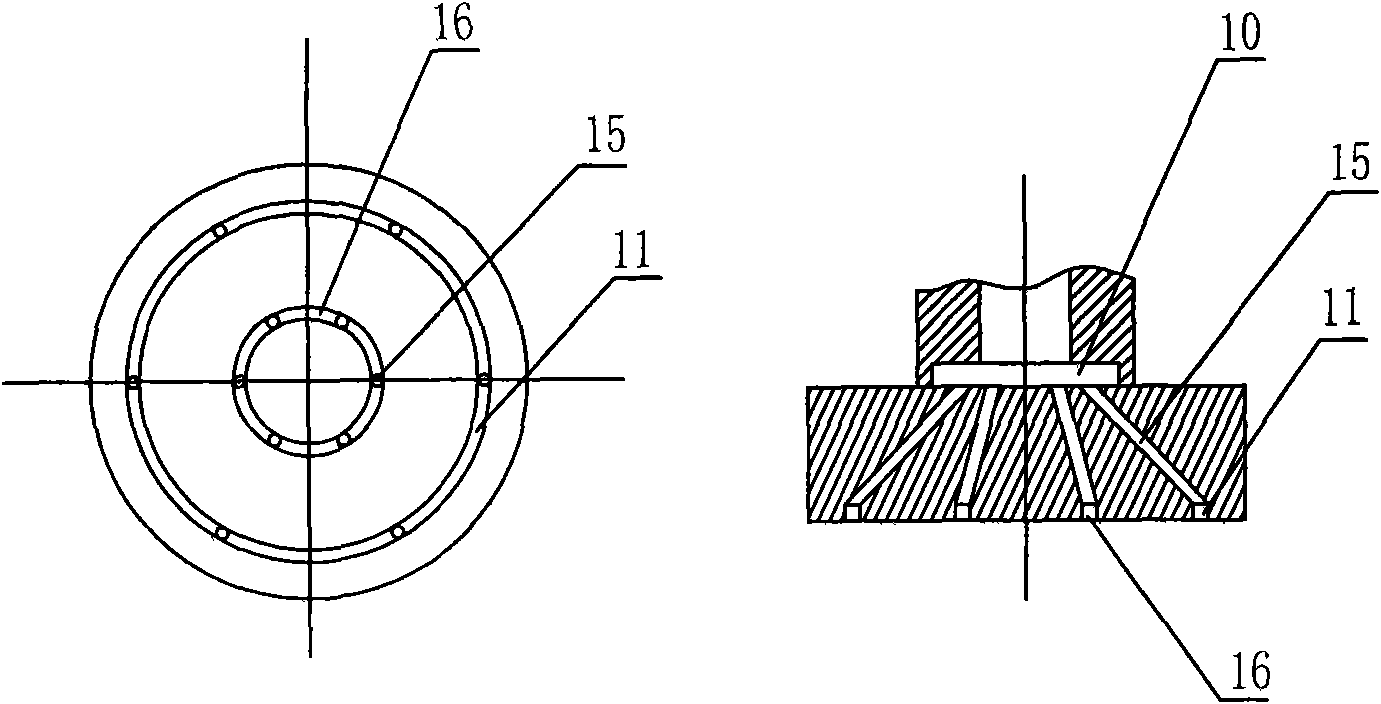

[0037]The engraving gravure polishing equipment of the present invention includes a control system 1, a pneumatic system, a frame 2, an X-axis servo mechanism, a Y-axis servo mechanism and a Z-axis servo mechanism, which can move along the Z-axis direction under the drive of the Z-axis servo mechanism The polishing device 5; the frame 2 is provided with an electromagnetic chuck 17 that can suck the gravure; the polishing device includes a constant pressure control cylinder 6 arranged on the Z-axis servo mechanism, an electric device arranged on the constant pressure control cylinder, and an electric device arranged on the electric motor. The polishing head 7 of device output end, the polishing pad 8 that is arranged on the polishing head 7, can provide the polishing liquid supply system of polishing liquid to the polishing head 7; The lower end surface of the polishing head 7 is also provided with a concentric polishing solution inner tank 16 with the polishing solution outer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com