High-performance as-cast austenite-bainite ductile iron and production method and application thereof

An austempered ductile iron and high-performance technology, which is applied in the field of metal material preparation, can solve the problems of increasing alloy cost and unfavorable application of as-cast austempered ductile iron, and achieves the effects of low production cost, good uniformity and widening application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

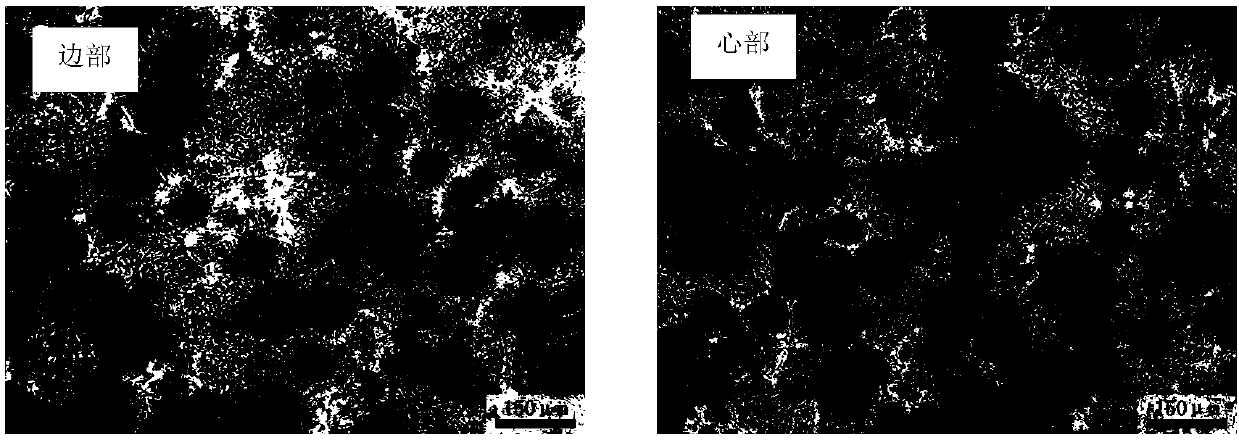

[0029] (1) Casting of ductile iron castings: make cylindrical samples with a diameter of 100mm and a maximum cross-sectional area of 100mm. According to the requirements of composition design, the cooling rate of simple samples is faster, and the lower limit of the content of three main alloying elements, Mo 0.3%, Ni 0.5%, Cu 0.5%, the rest of the elements are controlled in the following ranges, C3.0-4.5%, Si 2.0-3.5%, Mn 0.2-0.4%, P<0.05%, S<0.02%, Mg< 0.06%. The main raw material is low-sulfur Benxi cast iron, and the alloy is smelted with an induction furnace. The composition of molten iron after smelting is shown in Table 1. 0.9% Z6S nodularizing agent is used for spheroidizing treatment, and desulfurization and inoculation treatment are carried out before pouring; Shell mold casting, 3 shell molds are poured each time.

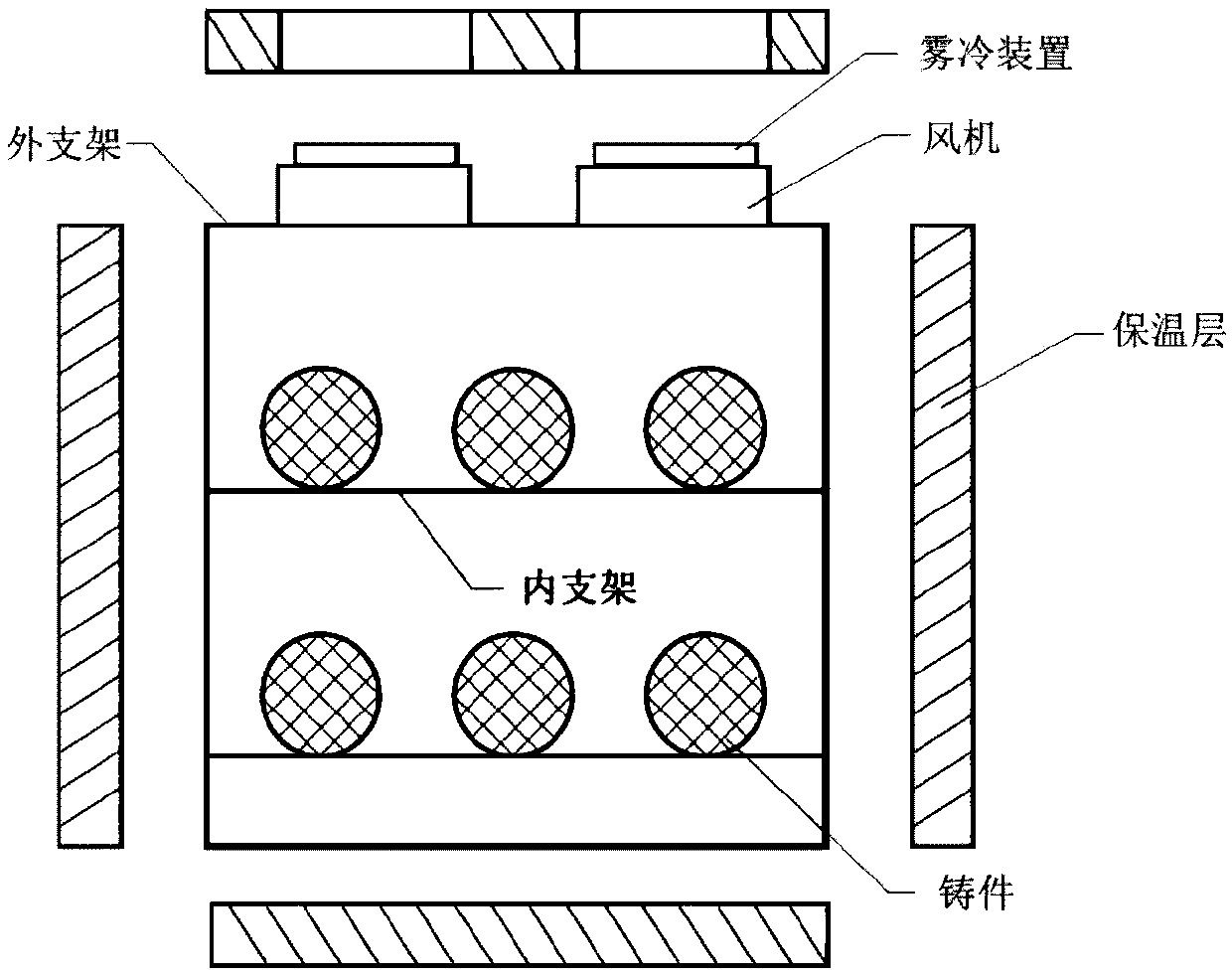

[0030] (2) Casting shelling process control: the pouring time of each shell shape is 10s, and the pouring interval is 1min; the shelling time of the f...

Embodiment 2

[0036] A diesel engine crankshaft is produced by using the high-performance as-cast austenitic ductile iron provided by the invention.

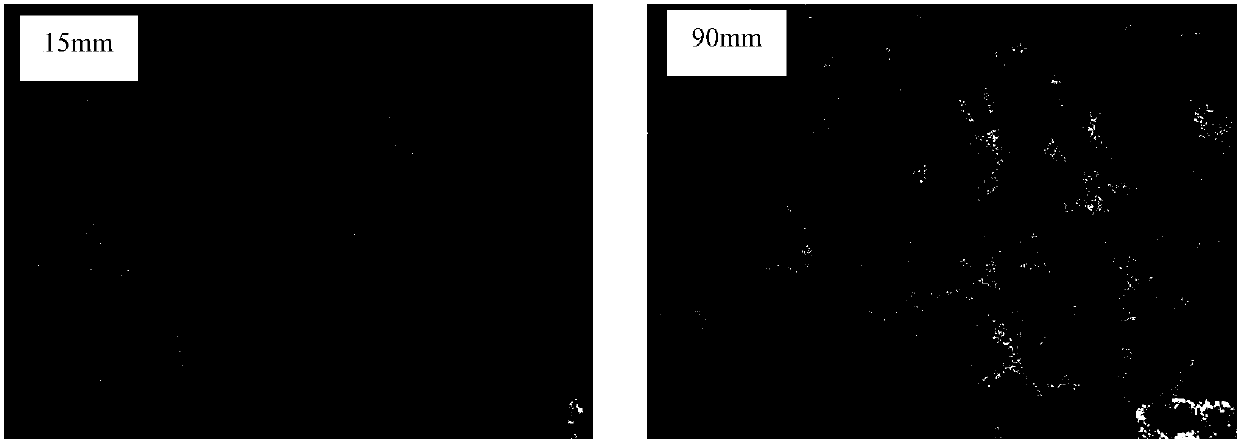

[0037] The main dimensions of the crankshaft (as shown in Table 2), the main journal, which is the largest bearing part of the crankshaft, reaches 90mm.

[0038] Table 2 Main dimensions of a diesel engine crankshaft (mm)

[0039] full length

main journal

connecting rod

650

Ф90

Ф74

58

Ф108

Ф45

[0040] The crankshaft production process is as follows:

[0041] (1) Casting of ductile iron castings: The chemical composition of the crankshaft is determined according to the 90mm main journal. Considering the complexity of the size of the crankshaft and the low cooling rate in the production process, the addition of the three main alloying elements has increased. Respectively: Mo 0.5%, Ni 0.8%, Cu 1.0%, the remaining elements are contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com