Heat resistant lubricant used for drawing refractory metal and preparation method thereof

A technology of high temperature resistant lubricants and refractory metals, applied in the direction of lubricating compositions, etc., can solve the problems of broken wires, scratches, low yield rate, etc., and achieve the effects of maintaining uniformity, improving lubricity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

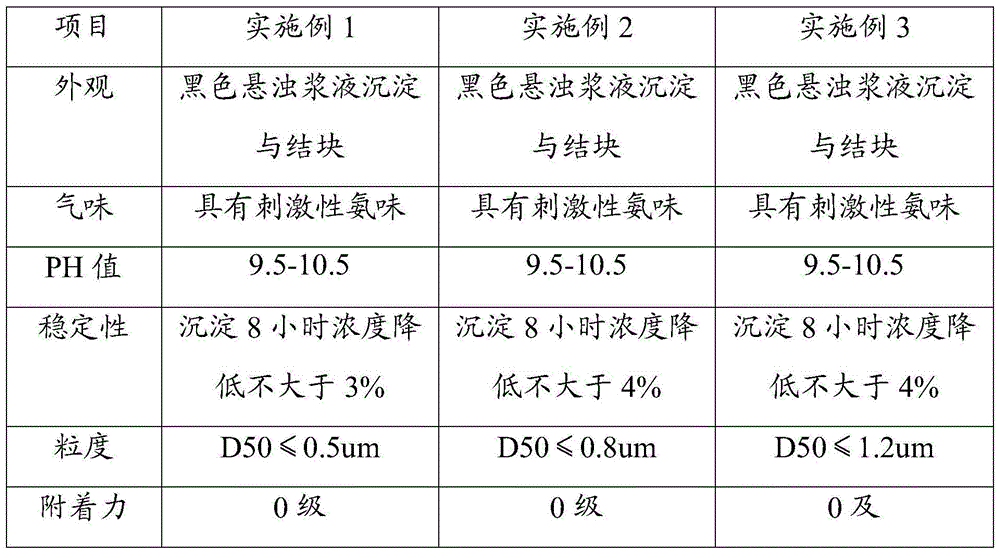

Embodiment 1

[0038] A high-temperature-resistant lubricant for refractory metal drawing, which is prepared from the following raw materials in weight percentage:

[0039] Graphite 12%, polyvinyl alcohol 0.6%, sodium carboxymethylcellulose 0.55%, Tween 0.1%, styrene acrylic emulsion 6%, polyethylene glycol 2%, sodium metasilicate 5%, 5,5-di Methylhydantoin 0.3%, ammonia water 4%, pure water to 100%;

[0040] Its preparation process is as follows:

[0041] 1) Prepare graphite powder

[0042] Pulverization: After the natural flake graphite is pulverized by air flow, the Z-30 bead mill is used to circulate the bead mill for 15-25 hours for wet pulverization;

[0043] Classification: The crushed graphite powder is centrifugally classified by a horizontal rough separator, and graphite particles with a particle size of less than 5 μm are screened out, and then subjected to high-speed centrifugal separation by a fine separator at 5000-6000 rpm to obtain graphite particles with a particle size of...

Embodiment 2

[0047] A high-temperature-resistant lubricant for refractory metal drawing, which is prepared from the following raw materials in weight percentage:

[0048] Graphite 19%, sodium methylene bis-naphthalene sulfonate 0.5%, sodium alginate 0.7%, sodium carboxymethylcellulose 0.75%, polyethylene glycol 2.6%, 5,5-dimethylhydantoin 0.3%, ammonia water 4.5%, sodium metasilicate 8%, pure water to make up to 100%;

[0049] Its preparation process is as follows:

[0050] 1) Prepare graphite powder

[0051] Pulverization: After the natural flake graphite is pulverized by air flow, the Z-30 bead mill is used to circulate the bead mill for 15-25 hours for wet pulverization;

[0052] Classification: The crushed graphite powder is centrifugally classified by a horizontal rough separator, and graphite particles with a particle size of less than 5 μm are screened out, and then subjected to high-speed centrifugal separation by a fine separator at 5000-6000 rpm to obtain graphite particles wit...

Embodiment 3

[0056] A high-temperature-resistant lubricant for refractory metal drawing, which is prepared from the following raw materials in weight percentage:

[0057] Graphite 22%, sodium methylene bis-naphthalene sulfonate 0.6%, sodium carboxymethyl cellulose 0.65%, sodium alginate 0.68, polyvinyl alcohol 0.5%, polyethylene glycol 3%, 5,5-dimethyl seawater Because 0.5%, ammonia water 5%, sodium metasilicate 10%, pure water make up to 100%;

[0058] Its preparation process is as follows:

[0059] 1) Prepare graphite powder

[0060] Pulverization: After the natural flake graphite is pulverized by air flow, the Z-30 bead mill is used to circulate the bead mill for 15-25 hours for wet pulverization;

[0061] Classification: The crushed graphite powder is centrifugally classified by a horizontal rough separator, and the graphite particles with a particle size of less than 5 μm are screened out, and then subjected to high-speed centrifugal separation by a fine separator at 5000-6000 rpm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com