Heterogeneous Fenton reagent and preparation method and application thereof

A heterogeneous reagent technology, applied in heterogeneous Fenton reagent and its preparation and application fields, can solve the problems of corrosion in the furnace, easy leakage of ammonia, large investment cost, etc., and achieve mild reaction conditions, easy process control, high The effect of denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

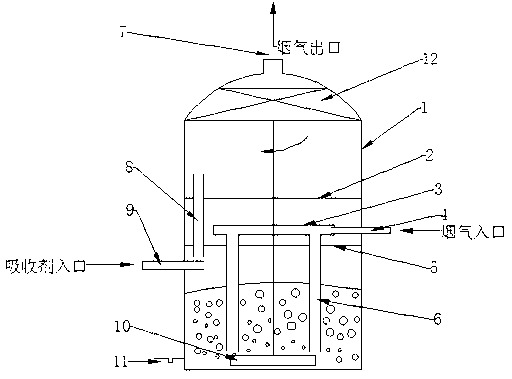

Image

Examples

Embodiment 1

[0040] A heterogeneous Fenton's reagent, namely by H 2 o 2 Aqueous solution and Al 2 o 3 The pH of the Fe catalyst composition is a mixed solution of 5, and the H in the mixed solution 2 o 2 The aqueous solution concentration is 1.0mol / L, Al 2 o 3 The supported Fe catalyst concentration is 2g / L;

[0041] The Al 2 o 3 In the supported Fe catalyst, calculated by mass ratio, that is, Al 2 o 3 : Fe is 4:1.

[0042] The preparation method of above-mentioned a kind of heterogeneous phase Fenton reagent, comprises the steps:

[0043] (1), Al 2 o 3 Preparation of supported Fe catalyst

[0044] First, configure 0.05mol / L FeSO 4 1000ml of aqueous solution was added to the stirred reactor, and N 2 0.5h to exclude dissolved oxygen, then add 10g of 100-mesh activated alumina, adjust the pH value to 4.0 with a NaOH solution with a concentration of 1mol / L, and then seal to prevent oxygen from entering. Stir on a stirrer for 24 hours, then filter, wash the obtained filter cake...

Embodiment 2

[0055] A heterogeneous Fenton's reagent, namely by H 2 o 2 Aqueous solution and Al 2 o 3 The pH of the Fe catalyst composition is a mixed solution of 5, and the H in the mixed solution 2 o 2 The aqueous solution concentration is 0.5mol / L, Al 2 o 3 The supported Fe catalyst concentration is 2g / L;

[0056] The Al 2 o 3 In the supported Fe catalyst, calculated by mass ratio, that is, Al 2 o 3 : Fe is 4:1.

[0057] The above-mentioned preparation method of a heterogeneous Fenton reagent is the same as in Example 1.

[0058] Using the heterogeneous Fenton reagent obtained in Example 2 to carry out wet flue gas denitrification, the details are the same as in Application Example 1, and the denitrification efficiency is 60.95%.

Embodiment 3

[0060] A heterogeneous Fenton's reagent, namely by H 2 o 2 Aqueous solution and Al 2 o 3 The pH of the Fe catalyst composition is a mixed solution of 5, and the H in the mixed solution 2 o 2 The concentration of the aqueous solution is 1.5mol / L, Al 2 o 3 The supported Fe catalyst concentration is 2g / L;

[0061] The Al 2 o 3 In the supported Fe catalyst, calculated by mass ratio, that is, Al 2 o 3 : Fe is 4:1.

[0062] The above-mentioned preparation method of a heterogeneous Fenton reagent is the same as in Example 1.

[0063] The heterogeneous Fenton reagent obtained in Example 3 was used to carry out wet flue gas denitrification, as in Example 1, and the denitrification efficiency was 67.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com