Combined type stirring system

A mixing system and composite technology, applied in the field of suspension storage and mixing equipment, can solve the problems of low degree of homogenization and low mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

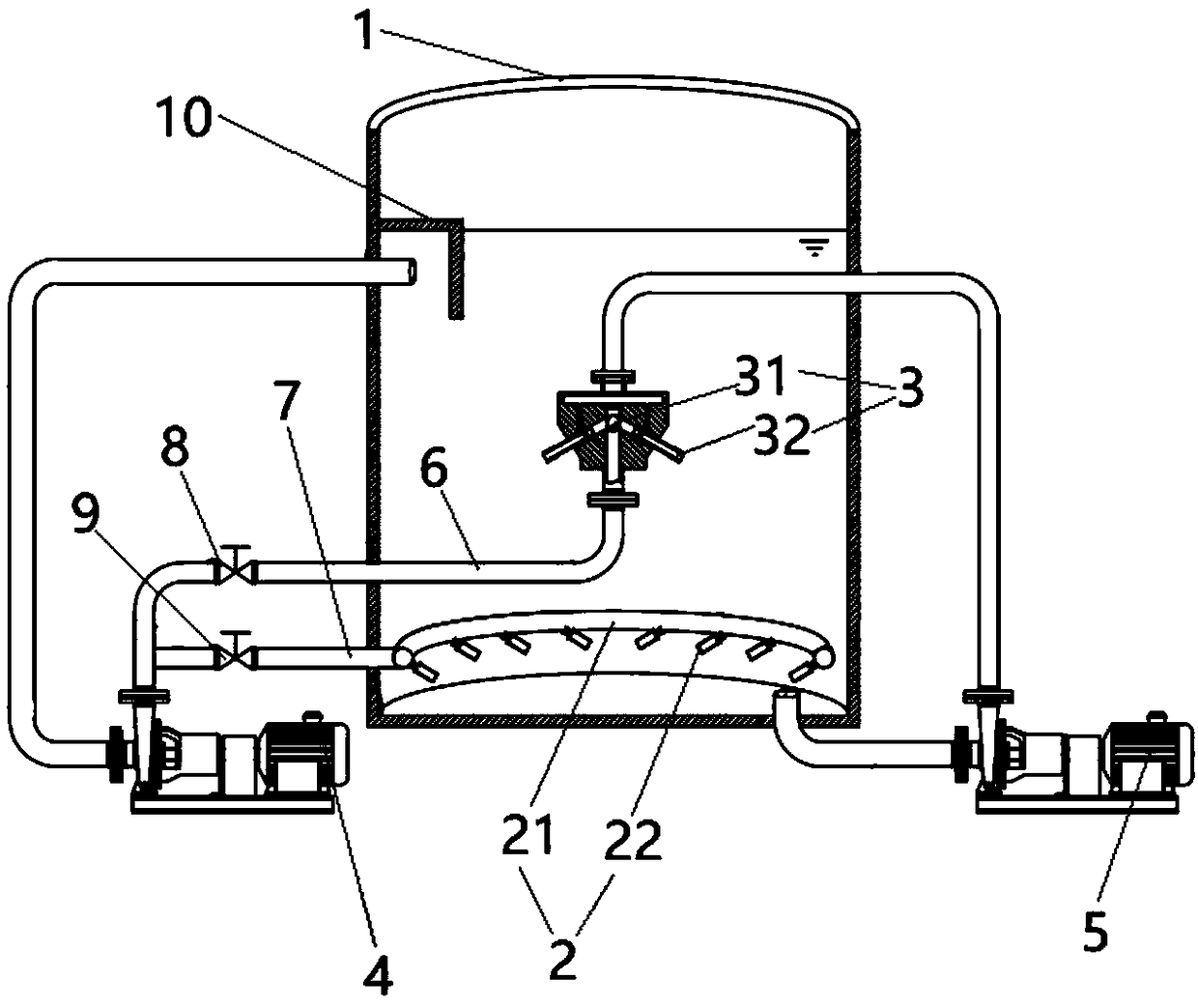

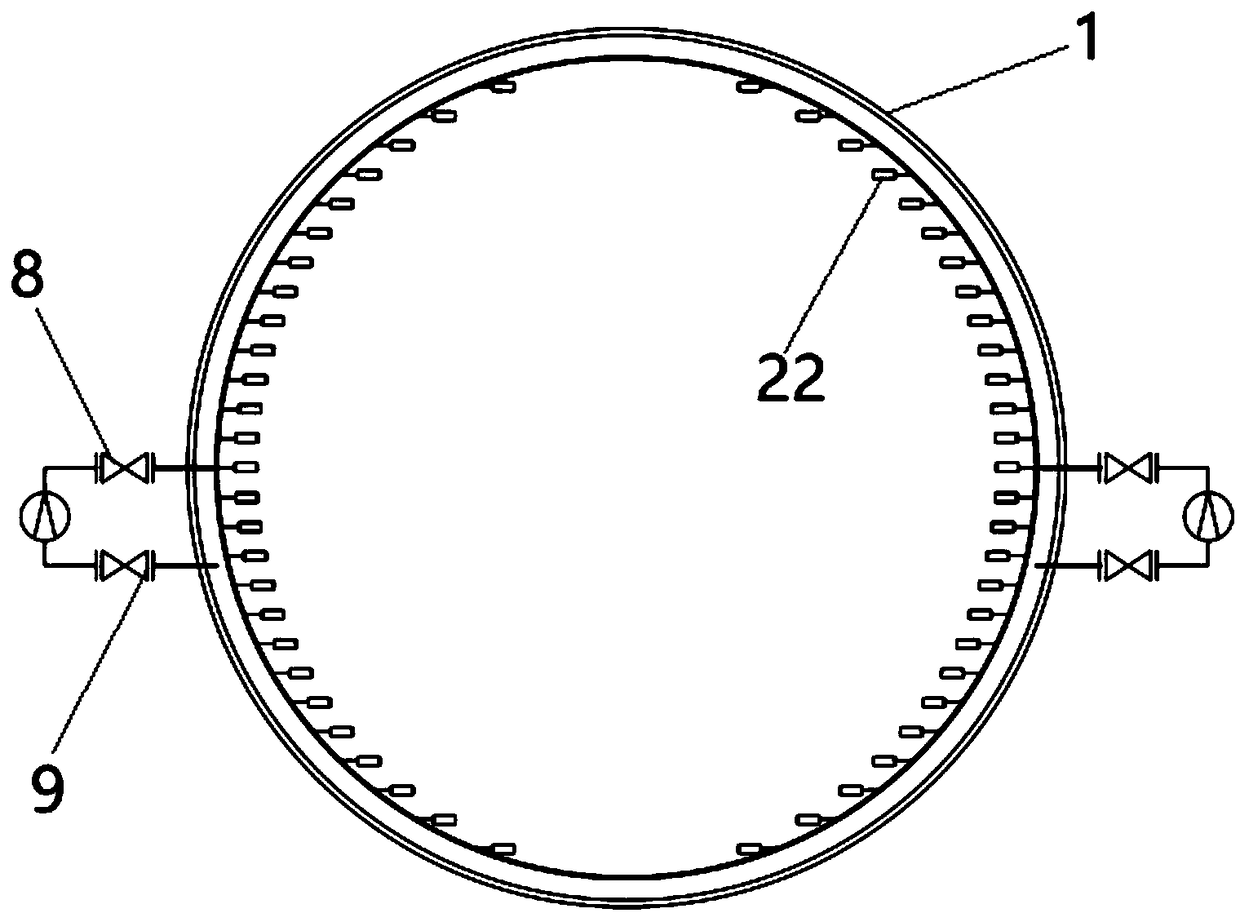

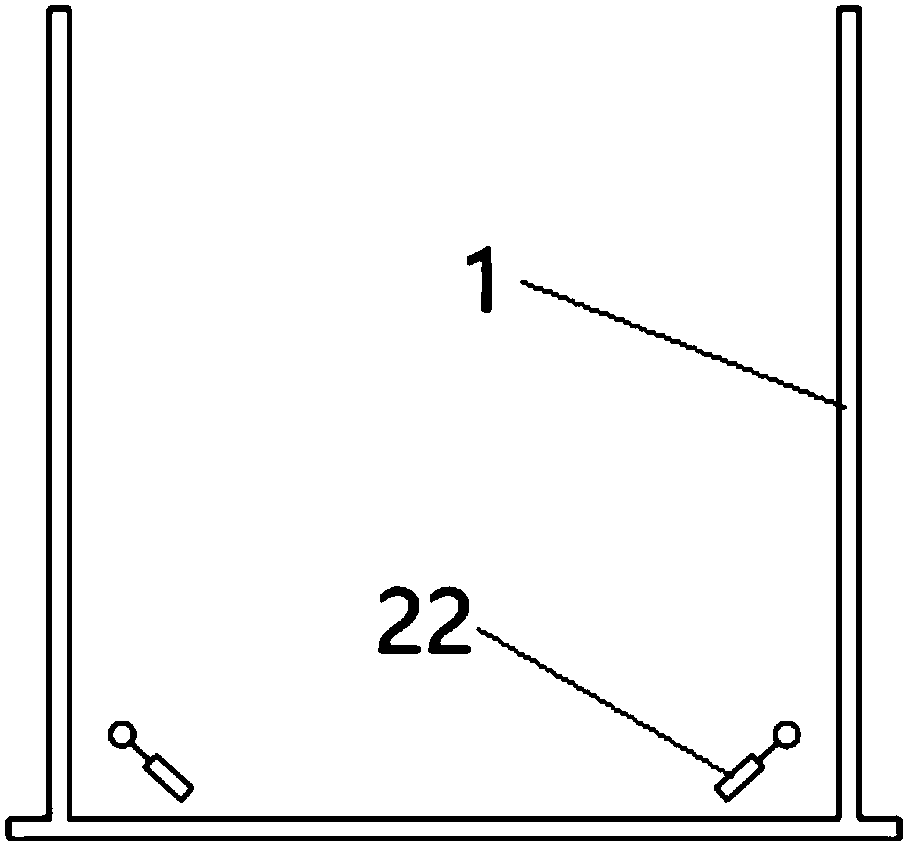

[0027] Such as figure 1 , 2 , 3, the composite mixing system provided by this embodiment includes: a mixing tank 1, a disc jet system 2, a center jet system 3, a first circulation pump 4, and a second circulation pump 5. The disc jet system 2 is arranged under the inside of the stirring tank 1 , and the central jet system 3 is located at the center of the stirring tank 1 . The inlet of the first circulation pump 4 is connected to the upper part of the inner cavity of the stirring tank 1, and the outlet of the first circulation pump 4 is connected to the first liquid outlet pipe 6 and the second liquid outlet pipe 7 at the same time, and the first liquid outlet pipe 6 and the central jet system 3 In communication, the second liquid outlet pipe 7 is connected with the disc fluidic system 2 . The inlet of the second circulation pump 5 is connected to the lower part of the inner chamber of the stirring tank 1 , and the outlet of the second circulation pump 5 is connected to the ...

Embodiment 2

[0037] This embodiment is basically the same in structure as the composite stirring system provided in Embodiment 1. In this embodiment, there are multiple central jet systems, and the multiple central jet systems are arranged at intervals along the axis of the stirring tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com