Liquid divider

A technology of liquid separator and distribution cavity, which is applied in the direction of refrigeration and liquefaction, fluid circulation arrangement, refrigeration components, etc. It can solve the problems of uneven flow of refrigerant and insufficient heat exchange capacity of evaporator, etc., and achieves compact structure, long length long, noise-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

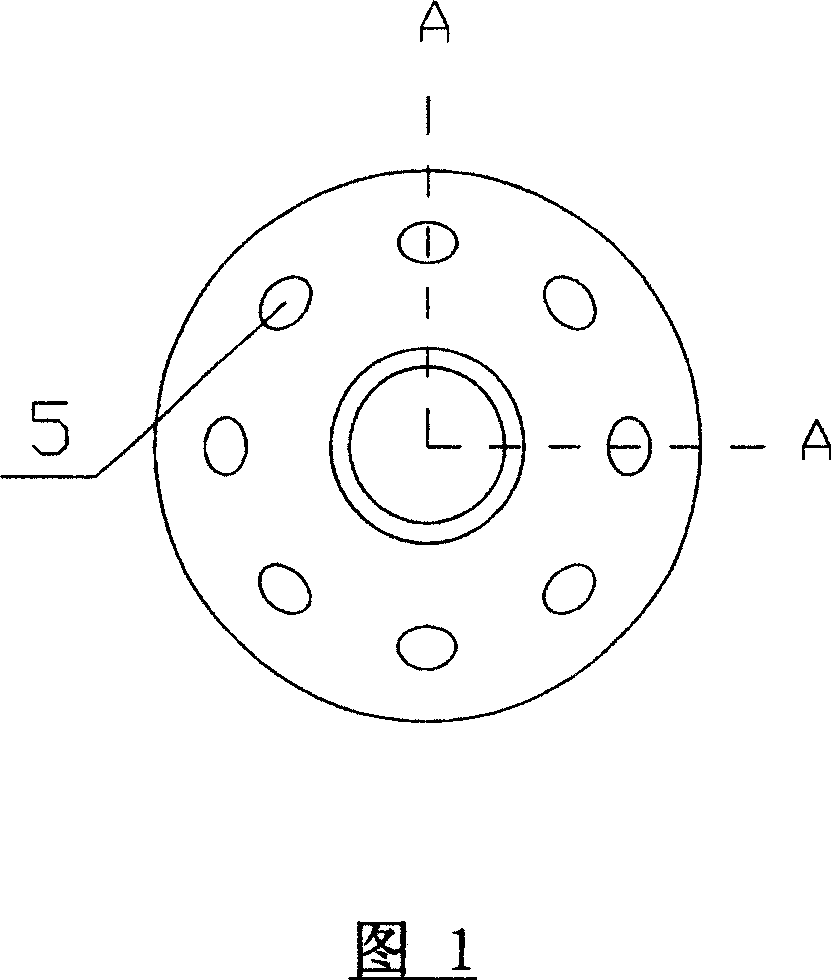

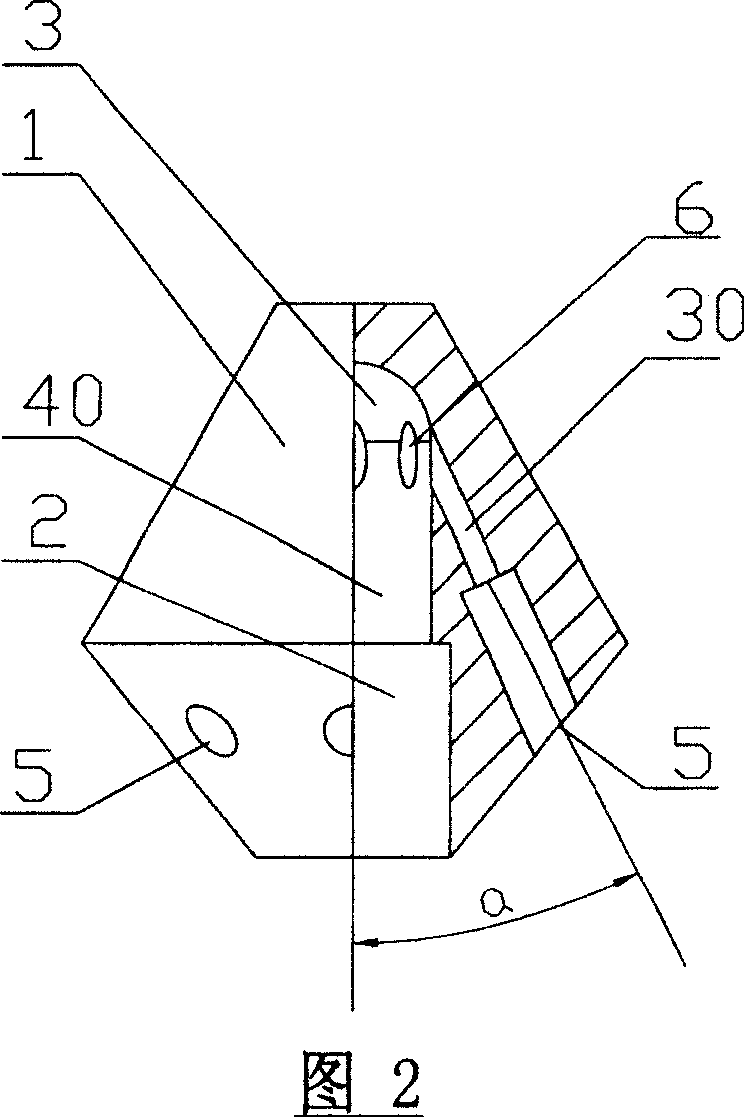

[0020] As shown in Fig. 2, the present invention provides a liquid distributor of an air conditioner, the liquid distributor includes a liquid distributor body 1, a main channel 40 in the liquid distributor body 1 and a liquid outlet chamber 30, and the main channel 40 includes a mixing chamber 2 and a distributing chamber 3. The distributing chamber 3 is branched radially and leads to a plurality of liquid outlet chambers 30. The distribution chamber 3 has a connecting opening 6 communicating with the branched liquid outlet chambers 30. , the angle a between the mixing chamber 2 and the liquid outlet chamber 30 is less than 90 degrees. The main channel 40 is composed of two parts: one part is the mixing chamber 2, and the mixing chamber 2 is composed of two cylindrical cavities with different diameters to form a stepped cylindrical cavity; the other part is the distributing chamber 3, and the The distribution chamber 3 is a part of the inner spherical cavity formed by the upw...

Embodiment 2

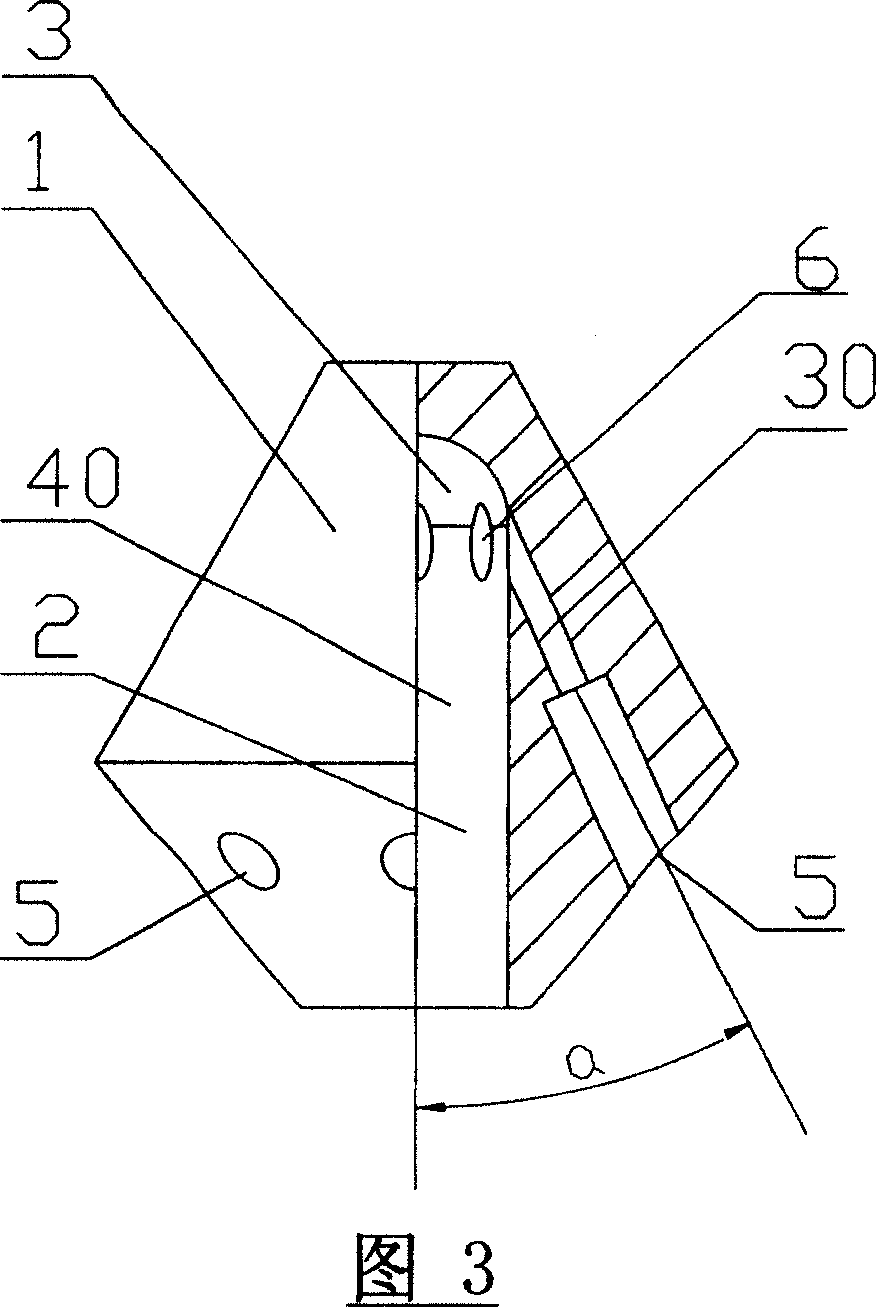

[0027] As shown in Figure 3, the biggest difference between this embodiment and Embodiment 1 is:

[0028] In this embodiment, the mixing chamber 2 of the main channel 40 is a cylinder with equal diameters rather than a stepped cylinder composed of two sections of cylinders with unequal diameters.

[0029] As shown in Figure 5 and Figure 7, the spray head 15 is inserted into the main channel 40 of the liquid distributor body 1, and the refrigerant enters the distribution chamber 3 of the liquid dispenser body 1 from the spray hole 16 of the spray head 15, and then passes through the distribution chamber 3 The connection opening 6 communicating with the liquid outlet chamber 30 enters the liquid outlet chamber 30 to achieve the purpose of diverting the refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com