Centrifugal device and cleaning device

A technology of centrifugal device and cleaning device, which is applied in the field of volute and impeller, which can solve the problems of large radial size and large radial size of the motor support, and achieve the effects of improving efficiency, increasing the length of the diffuser, and reducing flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

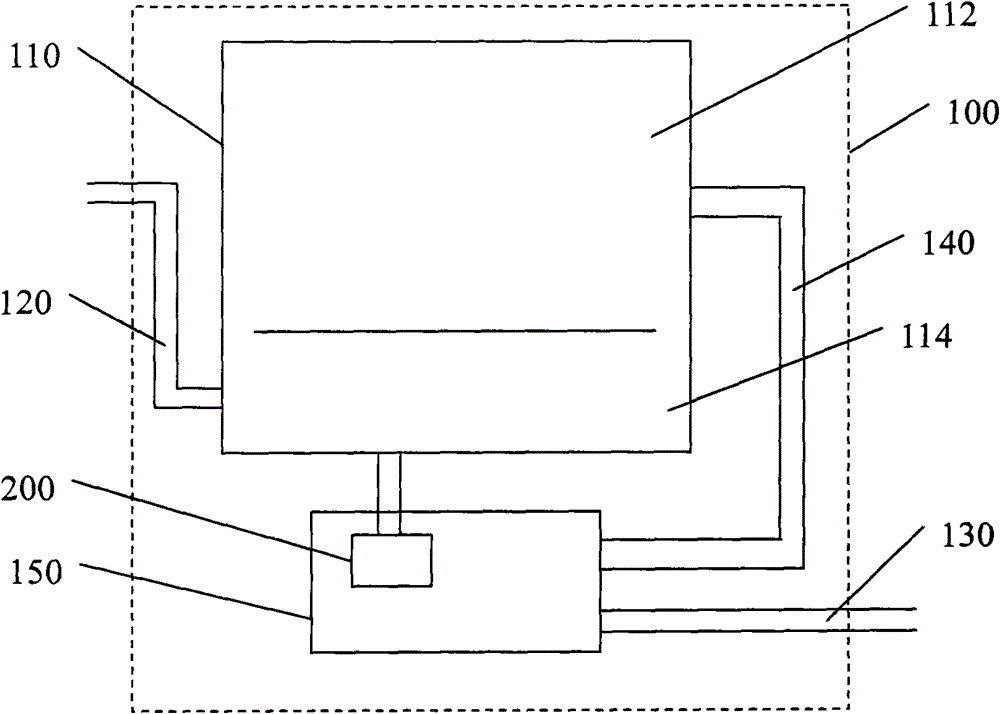

[0022] A cleaning device 100 provided in an embodiment of the present invention includes a housing 110 provided with a cleaning space 112 for accommodating objects to be cleaned and a water storage space 114 for retaining washing water, and is used to supply water to the water storage space 114 from the outside. The water supply channel 120 for delivering washing water, the drainage channel 130 for discharging the washing water to the outside, the circulation channel 140 for circulating the washing water in the water storage space 114 to the washing space 112, and the water storage space 114 for selectively The washing water in the water is circulated to the washing space 112 or sent to the control system 150 of the drainage channel 140 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com