Array jet plasma system and method for rapidly disinfecting surface pathogenic microorganisms

A technology of jet plasma and pathogenic microorganisms, used in disinfection, sanitary equipment for toilets, buildings, etc., can solve the problems of small coverage area, difficult power matching, high energy consumption, etc., to reduce the generation of harmful gases and break through technical bottlenecks , the effect of strengthening the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

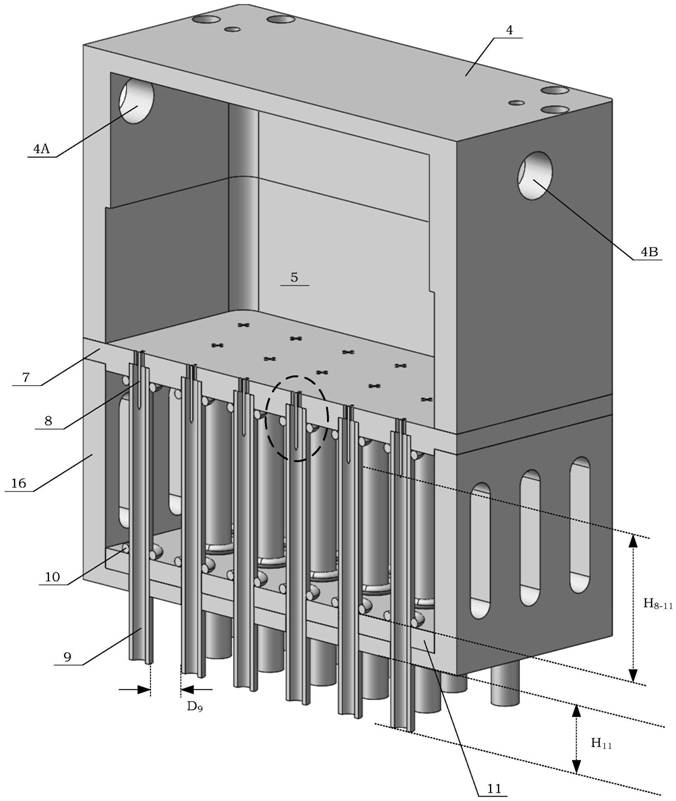

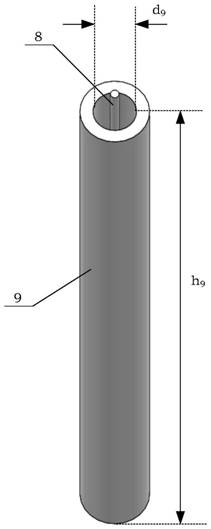

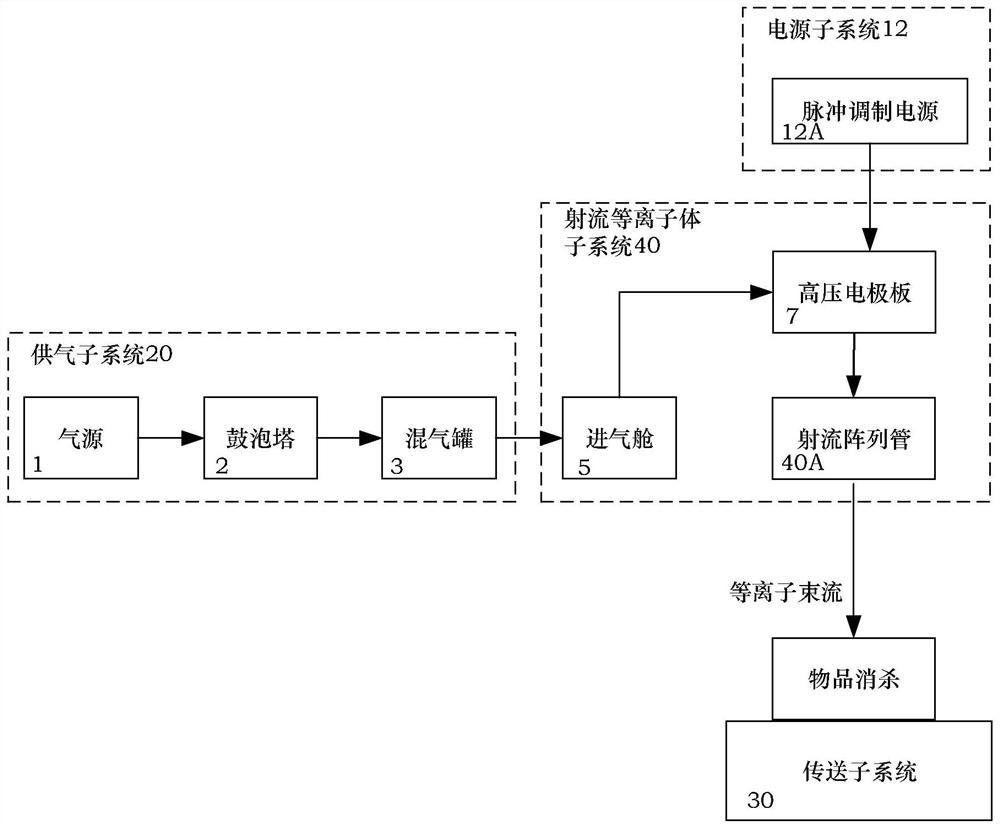

Embodiment 1

[0087] In Embodiment 1, the box size of the jet plasma subsystem 40 (such as image 3 shown), the length is denoted as A, the width is denoted as B, and the height is denoted as C, with a length of 150mm, a width of 150mm, and a height of 130mm, including 33 hollow medium pipes (9) arranged in an array, and the distance between adjacent hollow medium pipes ( D. 9 ) is 8mm. The diameter of the restrictor hole (6) is 0.52mm, and the inner diameter of the hollow medium pipe (9) (d 9 ) is 8mm, the outer diameter is 13mm, the length (h 9 ) is 85mm. The distance (H 8-11 ) is 40mm, the distance (H 11 ) is 25mm. The effective killing area of a single jet plasma subsystem 40 is 174.2cm 2 .

[0088] In Example 1, the gas composition is controlled by the gas supply subsystem 20 to be argon with a volume fraction greater than 99.9%, and the flow rate is 132 L / min, and then it is filled into the gas inlet chamber 5 of the jet plasma subsystem 40 and purged.

[0089] In Embodiment ...

Embodiment 2

[0093] In Embodiment 2, a jet plasma subsystem 40 of the same size as in Embodiment 1 is used.

[0094] In Embodiment 2, the gas composition is controlled by the gas supply system to be 95% argon by volume fraction, 5% oxygen, and the flow rate is 132L / min, which is then filled into the inlet chamber 5 of the jet plasma subsystem 40 and purged .

[0095] In Embodiment 2, under the atmosphere environment of the air inlet cabin 5 of the jet plasma subsystem 40, the modulated pulse power supply is switched on, and a high voltage of 10KV is applied to the high voltage electrode plate 7, and the sine frequency is adjusted to be 20kHz, and the pulse duty ratio is 60 %, the power of the power supply is 330w, and the voltage of the power supply is 200V, forming a large-area and uniform array plasma flow.

[0096] In Example 2, the object to be sterilized is placed on the conveying system, the distance between the hollow medium tube and the surface of the object is adjusted to be 15mm...

Embodiment 3

[0099] In Embodiment 3, a jet plasma subsystem 40 of the same size as in Embodiment 1 is used.

[0100] In Example 3, the gas composition is controlled by the gas supply system to be 95% argon by volume fraction, 2% N 2 O gas, with a flow rate of 132 L / min, is then filled into the intake chamber 5 of the jet plasma subsystem 40 and purged.

[0101] In Embodiment 3, under the atmosphere environment of the air inlet cabin 5 of the jet plasma subsystem 40, the modulated pulse power supply is switched on, a 15KV high voltage is applied to the high voltage electrode plate 7, and the sine frequency is adjusted to be 20kHz and the pulse duty ratio is 60. %, the power of the power supply is 330w, and the voltage of the power supply is 200V, forming a large-area and uniform array plasma flow.

[0102] In Example 3, the object to be sterilized is placed on the conveying system, the distance between the hollow medium tube and the surface of the object is adjusted to be 15 mm, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com