Electrospinning device, method and system for manufacturing nanofibers in batch

A nanofiber and electrospinning technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc. It can solve the problems of difficult cleaning, inconsistent spraying state, and large difference in nanofiber shape and size, and achieves deposition of fibers Uniform, induced easy spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

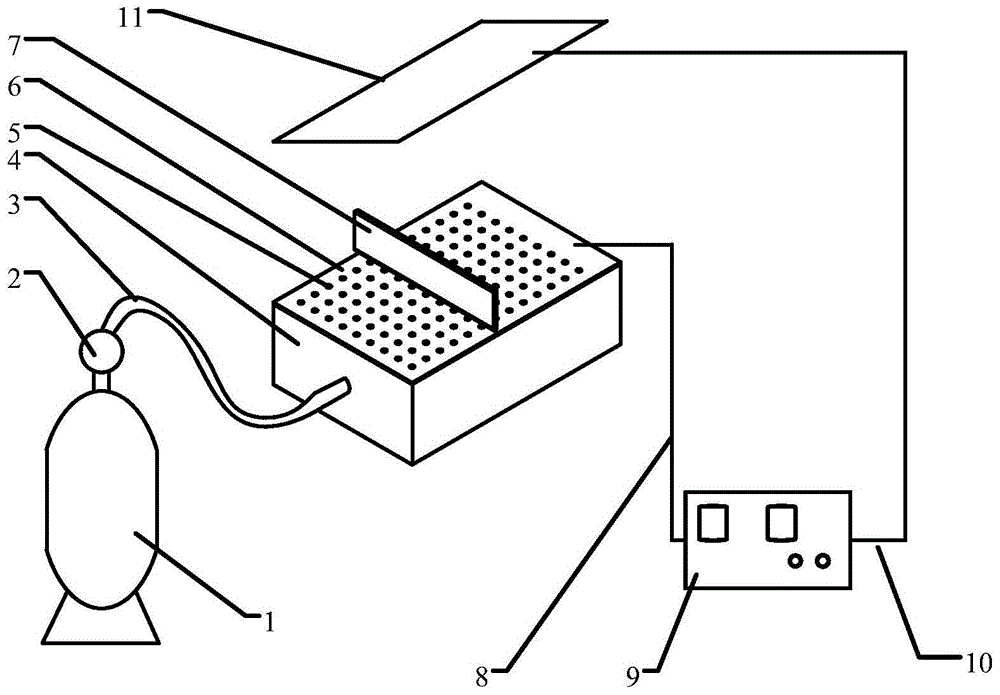

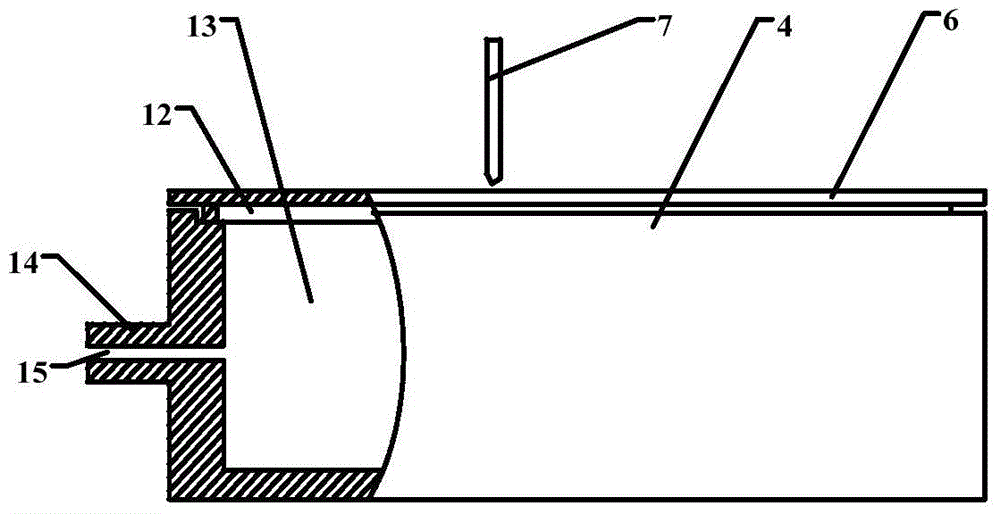

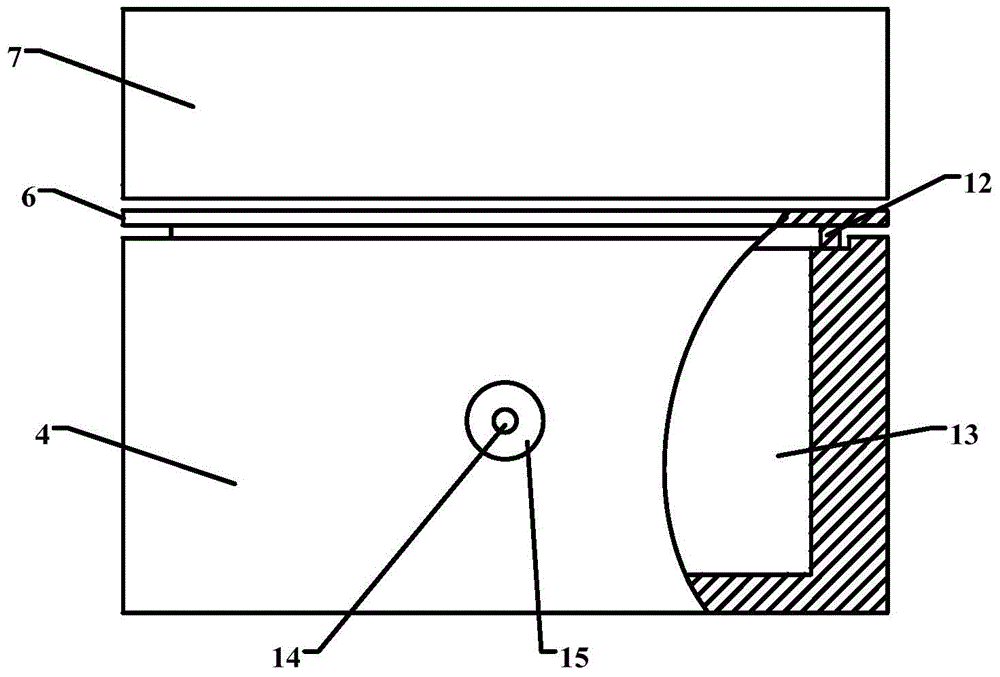

[0035] Such as Figure 1 to Figure 4 The electrospinning device for batch manufacturing of nanofibers shown includes an air chamber 13, an air supply unit, a scraper 7, a conductive collector 11 and a power source 9.

[0036] The air chamber 13 is surrounded by a box body 4 and a plate electrode 6. The upper end of the box body 4 is opened, and the plate electrode 6 covers the opening. A sealing ring 12 is arranged on the connecting surface of the box body 4 and the plate electrode 6 to ensure that the connecting surface of the two does not leak air.

[0037] A number of micropores 5 are uniformly opened on the plate electrode 6. These micropores 5 are perpendicular to the plane where the plate electrode 6 is located and communicate with the air chamber 13 and the outside. When the air chamber 13 is filled with gas, air flow can flow out of the micropores 5.

[0038] The air supply unit is located outside the air chamber 13 and supplies air to the air chamber 13, and is specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com