Atmospheric pressure discharge cold plasma generator based on double gas source

A cold plasma and generator technology, applied in the directions of plasma and electrical components, can solve the problems of reducing the service life of the cold plasma generator, increasing the cost of using the cold plasma technology, etc., so as to reduce the working cost and achieve rapid processing capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

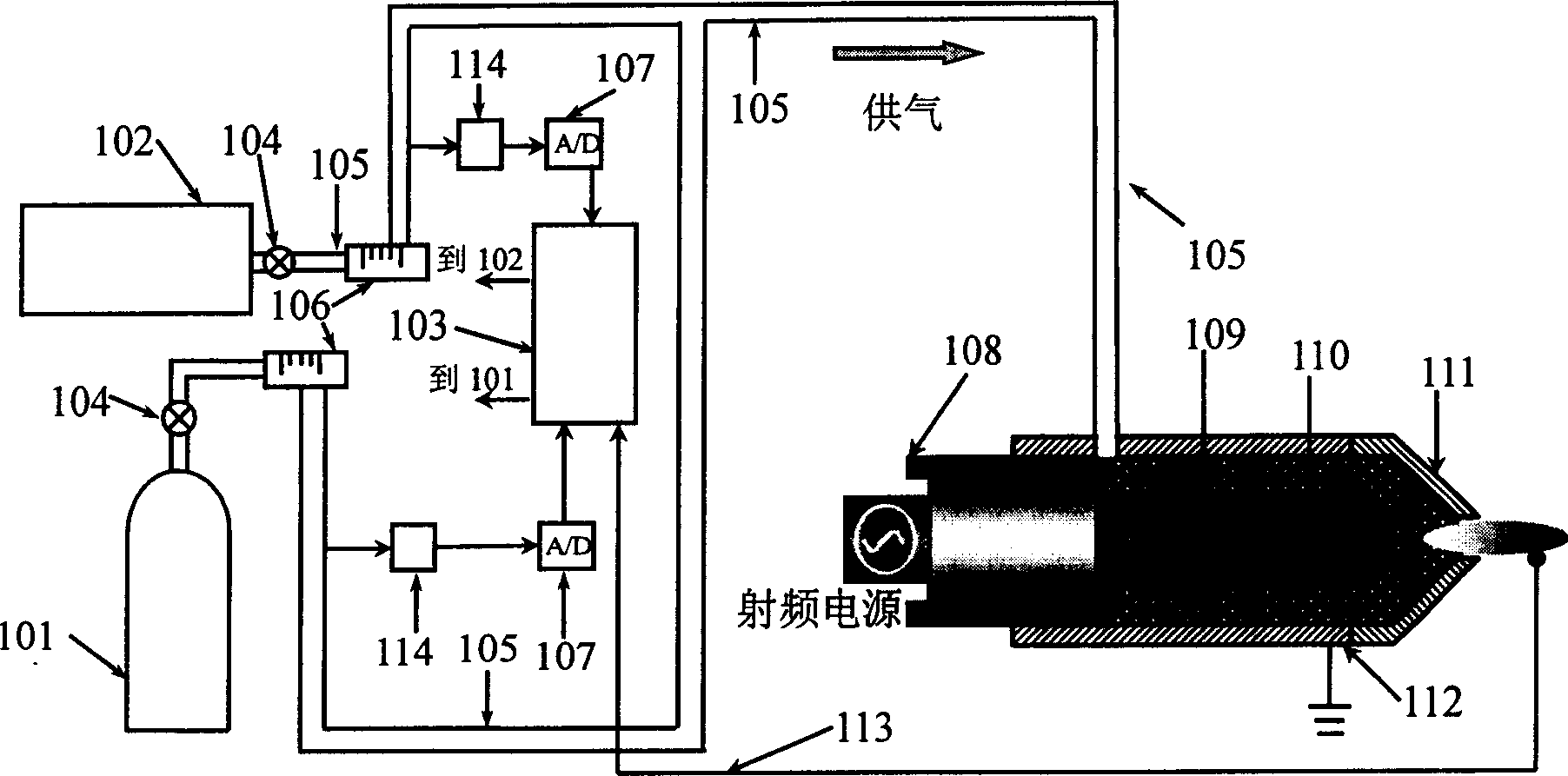

[0040] The application adopts such as figure 1 Dual gas source gas supply system shown. By making the gas that can discharge stably under atmospheric pressure (such as helium, argon, etc.) discharge first, and then increase the flow of gas that cannot discharge stably under atmospheric pressure (such as air, nitrogen, etc.), induce its discharge, and at the same time gradually close the inducing gas ( gas that can be stably discharged under atmospheric pressure), and finally realize the discharge of gas that cannot be stably discharged under atmospheric pressure such as air and nitrogen, thereby expanding the types of working gases for atmospheric pressure discharge cold plasma, and greatly reducing the use cost of this technology.

[0041] figure 1 Schematic diagram of the dual gas source gas supply system. Among them, 101 is an inducing gas source (a gas source that can discharge stably under atmospheric pressure, such as a helium gas bottle, an argon gas bottle, etc.), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com