Atomizer nozzle for a sanitary water outlet and sanitary outlet fitting with a water outlet

A technology of atomizing nozzles and water outlet devices, which is applied in the field of sanitary water outlet accessories, and can solve problems such as complex structures and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

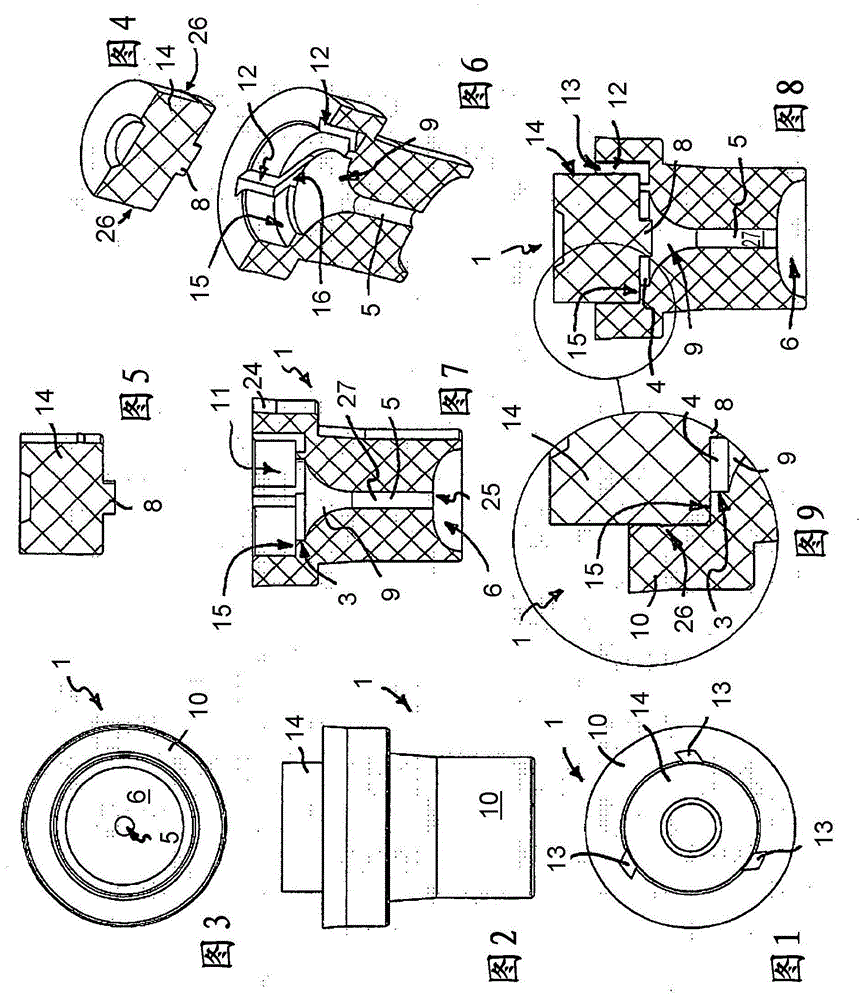

[0060] exist Figures 1 to 16 shows an atomizing nozzle 1 which is used in a sanitary water outlet to atomize water under pressure. The atomizing nozzle 1 should form a uniform water jet with a large volume from a small volume flow.

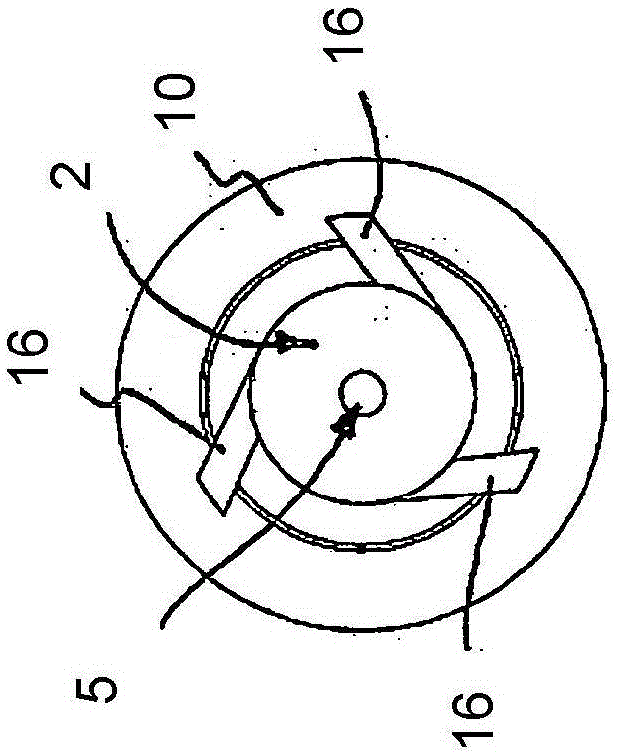

[0061] The atomizing nozzle 1 has a swirl chamber 2 which, on the inflow side, has a chamber section 3 with an approximately cylindrical or disk-shaped clear cross-section. At least one supply channel 4 oriented transversely and preferably perpendicularly to the longitudinal axis of the nozzle and tangentially into the swirl chamber 2 opens into the swirl chamber 2 .

[0062] Such as Figure 11 Visible in the top view of , which shows grooves 16 each forming a supply channel, here a plurality of supply channels 4 open into the vortex chamber 2 , said supply channels being evenly spaced apart from one another in the circumferential direction. The vortex chamber 2 tapers funnel-shaped in the outflow direction in the direction of the nozzle chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com