Surface treatment process system and process of automobile plastic parts

A surface treatment and process system technology, applied in the field of auto parts processing, can solve the problems of no grade, multiple burrs, extra noise, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

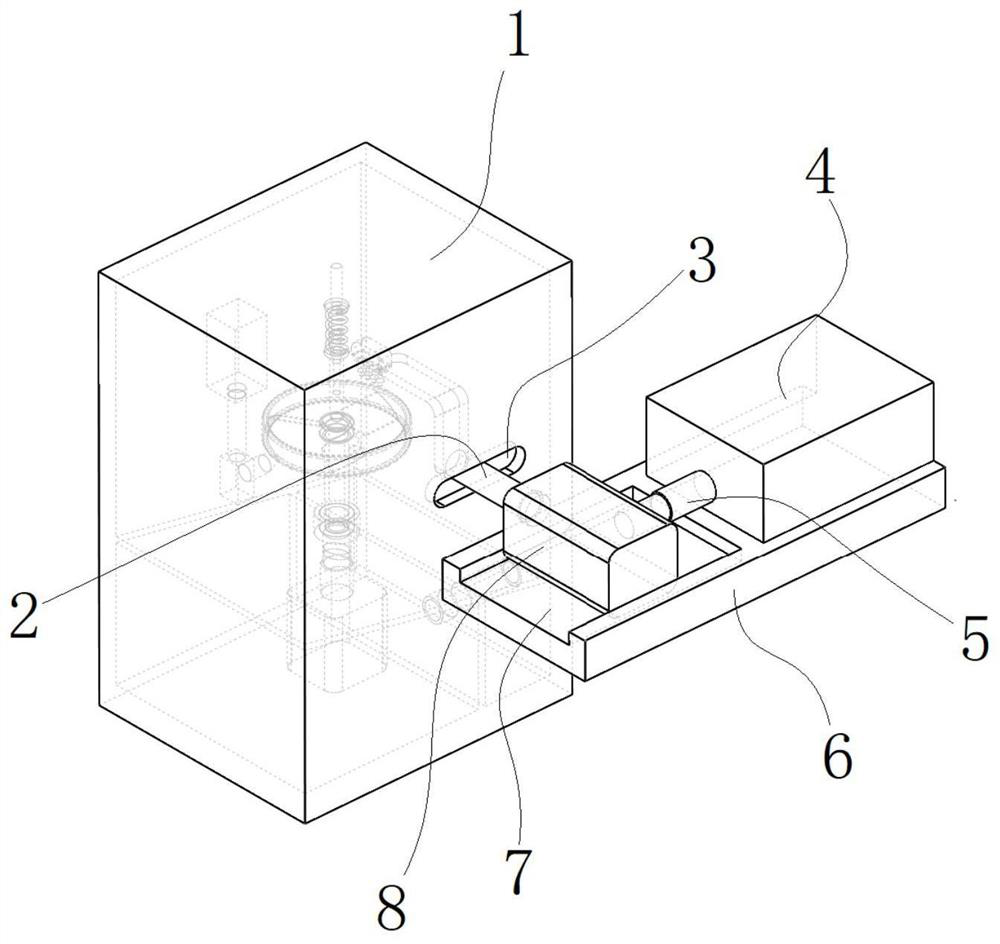

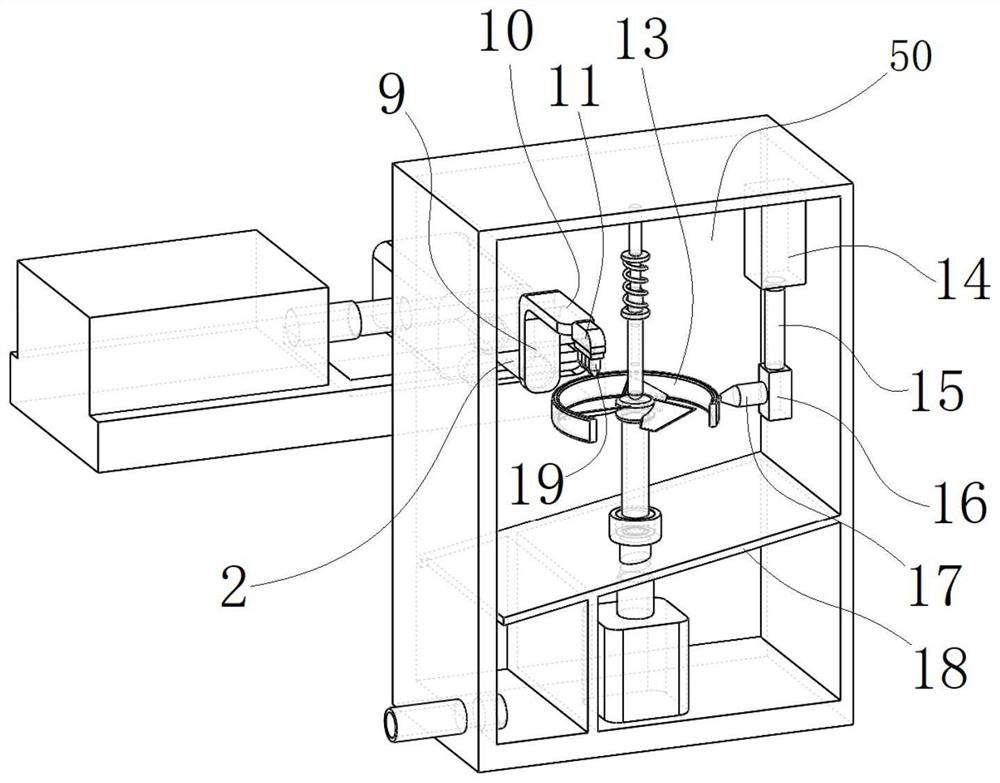

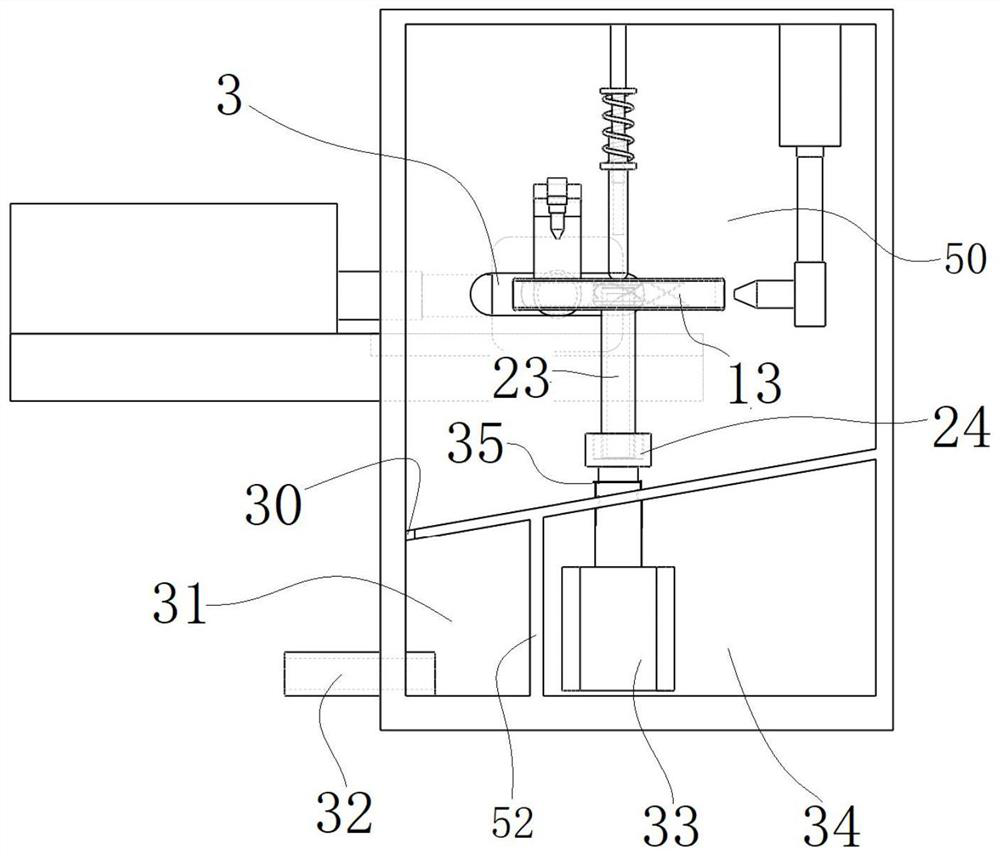

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] as attached Figures 1 to 8 The surface treatment process system for plastic parts of automobiles shown includes a liquid sandblasting and grinding box 1, and an inclined deflector 18 is arranged inside the liquid sandblasting and grinding box 1, and the upper side of the deflector 18 is jet grinding. Chamber 50, the lower side of the deflector 18 is provided with a vertical partition 52, the left side of the partition 52 is the waste liquid chamber 31, and the right side of the partition 52 is the lifting motor chamber 34; The short end of deflector 18 is provided with leakage hole 30, and described leakage hole 30 connects the bottom end of described jet grinding chamber 50 to described waste liquid chamber 31; Also comprises waste liquid discharge pipe 32, and described waste liquid The feeding end of the discharge pipe 32 is connected to the waste liquid ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com