Simple atmosphere pressure suspending electrode cold plasma fluid generator

A technology of cold plasma and jet generator, applied in the directions of plasma, circuit, discharge tube, etc., can solve the problems of reducing the stability of the atmospheric pressure cold plasma jet, increasing the complexity of operation, control and maintenance, and the structure of the jet source being complicated. , to achieve the effect of improving energy utilization, long continuous working time, and optimizing jet characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

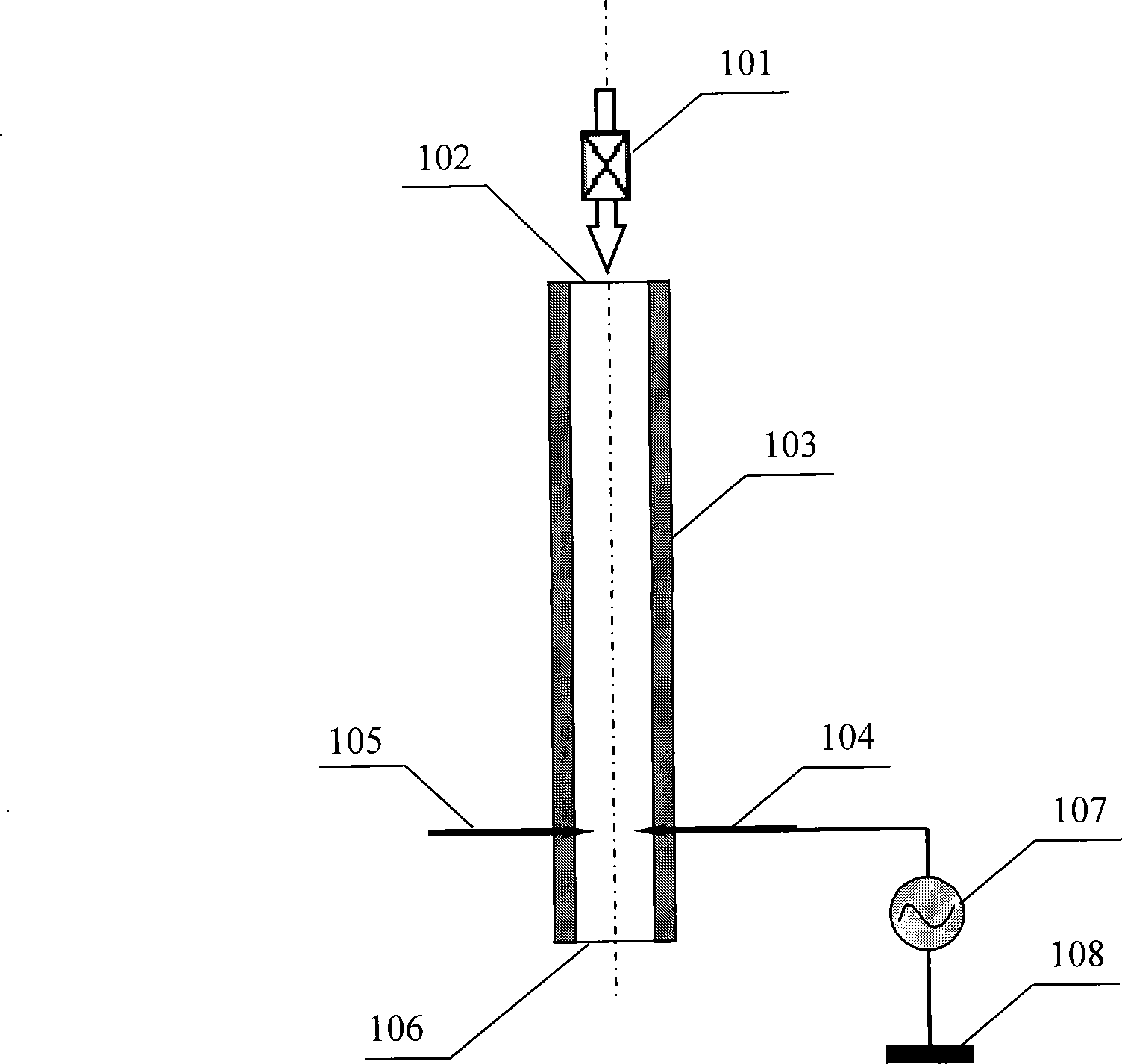

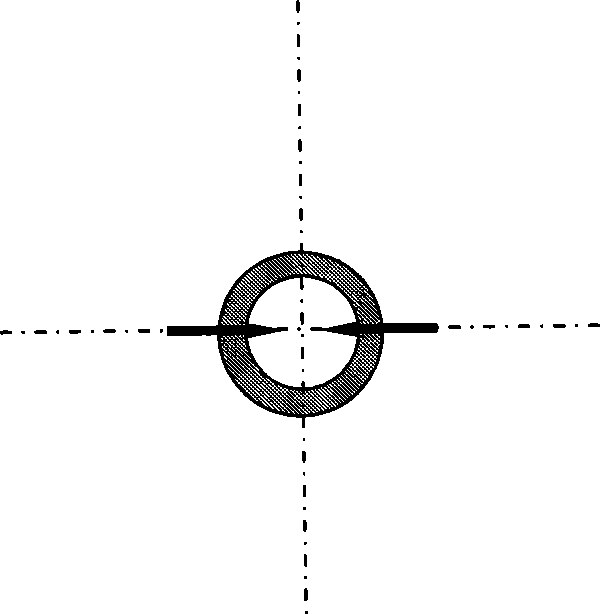

[0024] Using high-purity argon with a purity of 99.999% as the working gas, the lower limit of the flow rate that can produce steady-state jets and unsteady-state jets is 0.08m 3 / h. When the flow rate is 0.26m 3 / h, the threshold voltage and jet characteristics of each stage are as follows:

[0025] 1. When a discharge is generated between two needle electrodes, the breakdown threshold for forming a low-intensity micro-arc is 2.7kV.

[0026] 2. Further increase the voltage, the voltage range of steady-state jets is 3.6kV-4.4kV; the macroscopic temperature range of steady-state jets is 18.7°C-22.3°C, and the electron excitation temperature is 3329K-3715K; the length of the jets is always kept at about 60mm .

[0027] 3. Continue to increase the voltage, the voltage range of the unsteady jet is 4.4kV-5.6kV; the electron excitation temperature is 3329K-4405K; the length of the unsteady jet is slightly shorter than the steady jet, about 40mm-60mm.

[0028] 4. When the applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com