Laminar plasma jet stabilizing method

A plasma and stable laminar flow technology, applied in the field of plasma jet, can solve the problems of increasing the difficulty of plasma source control, unreasonable use of energy resources, and increasing the volume of plasma source, so as to reduce the pressure difference and improve effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

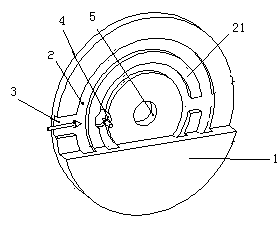

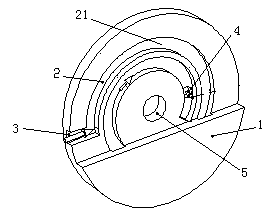

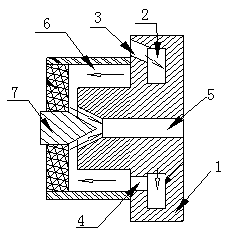

Image

Examples

Embodiment 1

[0028] As a preferred embodiment of the present invention, this embodiment discloses a method for stabilizing a laminar plasma jet, and this embodiment includes the following steps:

[0029] Cooling step: when the plasma source is working, the working gas first enters the inside of the anode body, and when the working gas circulates inside the anode body, the working gas cools the anode body, and at the same time, the excess energy on the anode body is transmitted to the working gas, and the working gas The temperature is raised; the working gas is then output from the anode body to the

[0030] Airflow transportation steps: the working gas circulates in the airflow channel between the casing and the anode body, and the temperature of the working gas in the airflow channel is maintained or continuously raised; then transported to

[0031] Plasma jet step: the working gas flows from the gas flow channel into the arc channel, the working gas is heated and ionized into plasma in ...

Embodiment 2

[0033] As another preferred embodiment of the present invention, this embodiment discloses a method for stabilizing a laminar plasma jet, and this embodiment includes the following steps:

[0034] Cooling step: when the plasma source is working, the working gas first enters the inside of the anode body, and when the working gas circulates inside the anode body, the working gas cools the anode body, and at the same time, the excess energy on the anode body is transmitted to the working gas, and the working gas The temperature is raised; the working gas is then output from the anode body to the

[0035] Airflow transportation steps: the working gas circulates in the airflow channel between the casing and the anode body, and the temperature of the working gas in the airflow channel is maintained or continuously raised; then transported to

[0036] Plasma jet step: the working gas flows from the gas flow channel into the arc channel, the working gas is heated and ionized into plas...

Embodiment 3

[0040] As another preferred embodiment of the present invention, this embodiment discloses a method for stabilizing a laminar plasma jet, and this embodiment includes the following steps:

[0041] Cooling step: when the plasma source is working, the working gas first enters the inside of the anode body, and when the working gas circulates inside the anode body, the working gas cools the anode body, and at the same time, the excess energy on the anode body is transmitted to the working gas, and the working gas The temperature is raised; the working gas is then output from the anode body to the

[0042]Airflow transportation steps: the working gas circulates in the airflow channel between the casing and the anode body, and the temperature of the working gas in the airflow channel is maintained or continuously raised; then transported to

[0043] Plasma jet step: the working gas flows from the gas flow channel into the arc channel, the working gas is heated and ionized into plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com