Atomizing nozzle used for sanitary water outlet unit and sanitary faucet with water outlet unit

A technology of atomizing nozzles and water outlet parts, which is applied in the field of sanitary water faucets, and can solve problems such as manufacturing difficulties and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

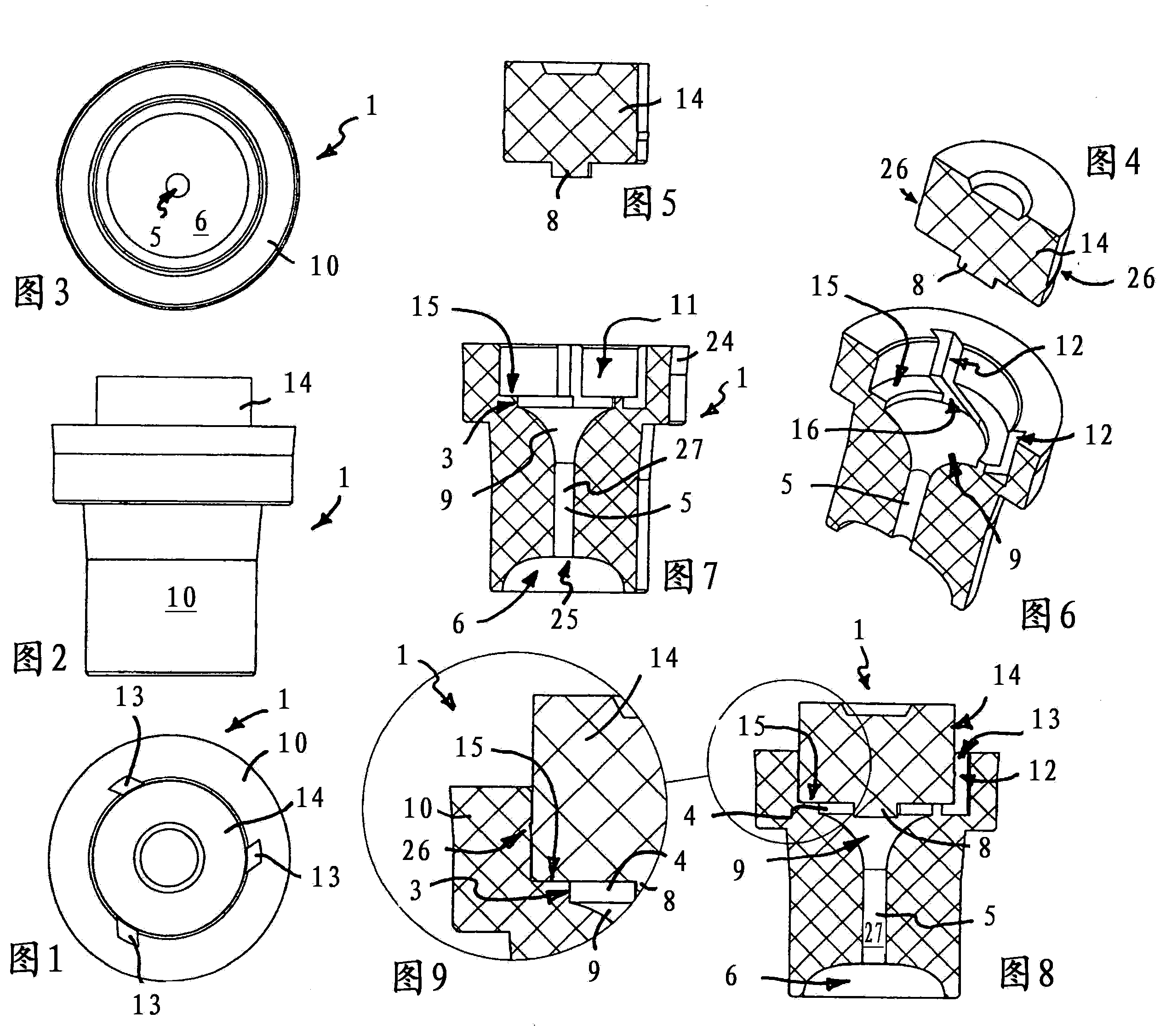

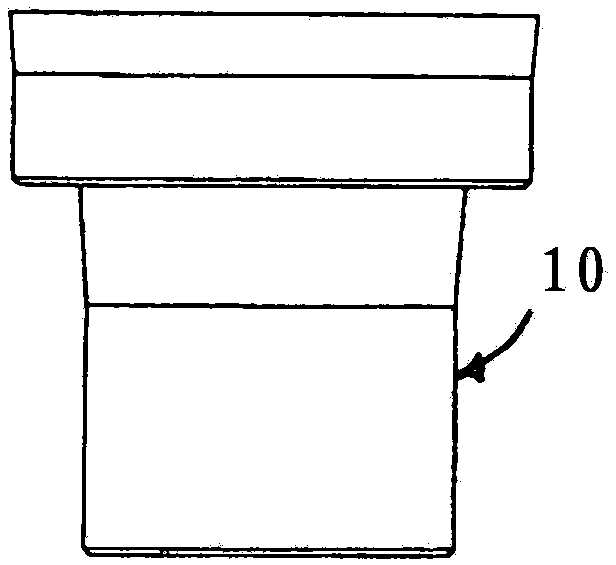

[0061] exist Figures 1 to 16 shows an atomizing nozzle 1 which is intended for a sanitary outlet for atomizing water under pressure. Whether the atomizing nozzle 1 is to be formed from a small volume stream or into an apparently volumetric, homogeneous water jet.

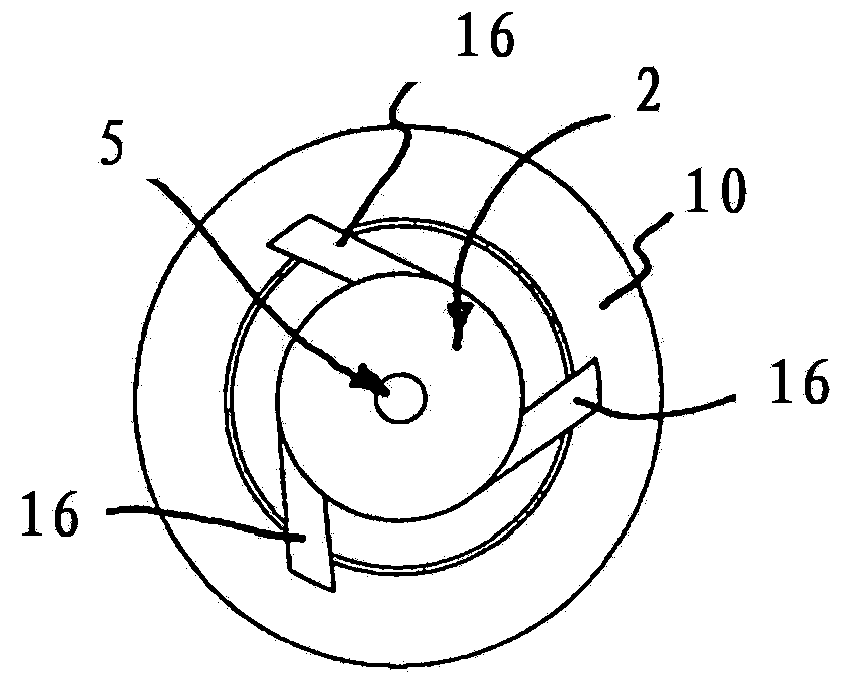

[0062] The atomizing nozzle 1 has a swirl chamber 2 which, on the inflow side, has a chamber section 3 with a substantially cylindrical or disk-shaped clear cross section. At least one supply channel 4 oriented transversely and preferably perpendicularly to the longitudinal axis of the nozzle and tangentially into the swirl chamber 2 opens into the swirl chamber 2 .

[0063] as in Figure 11 It can be seen in the top view in that the grooves 16 each forming a supply channel are shown in this figure, here a plurality of supply channels 4 which are evenly spaced apart from one another in the circumferential direction open into the vortex chamber 2 . The vortex chamber 2 tapers funnel-shaped in the outflow directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com