Gas gap pressure stabilizer

A voltage stabilizer and gas technology, applied in the direction of hull, hull design, hydrodynamic characteristics/hydrostatic characteristics, etc., can solve the problems of difficult implementation of gas lubrication drag reduction technology, low speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

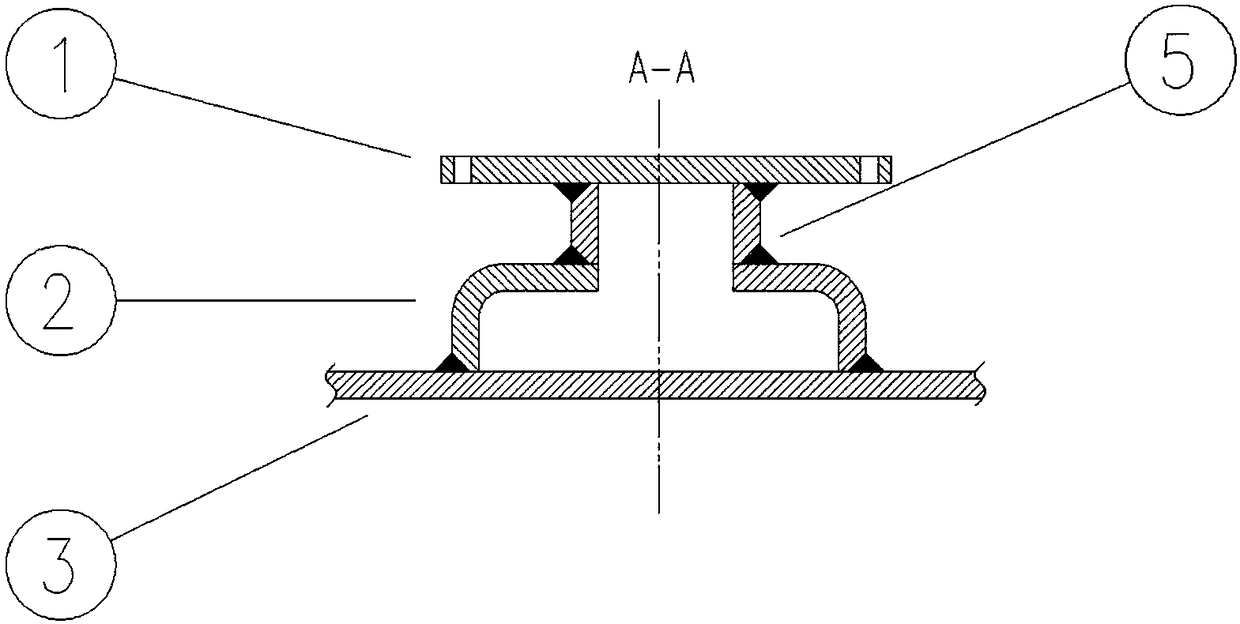

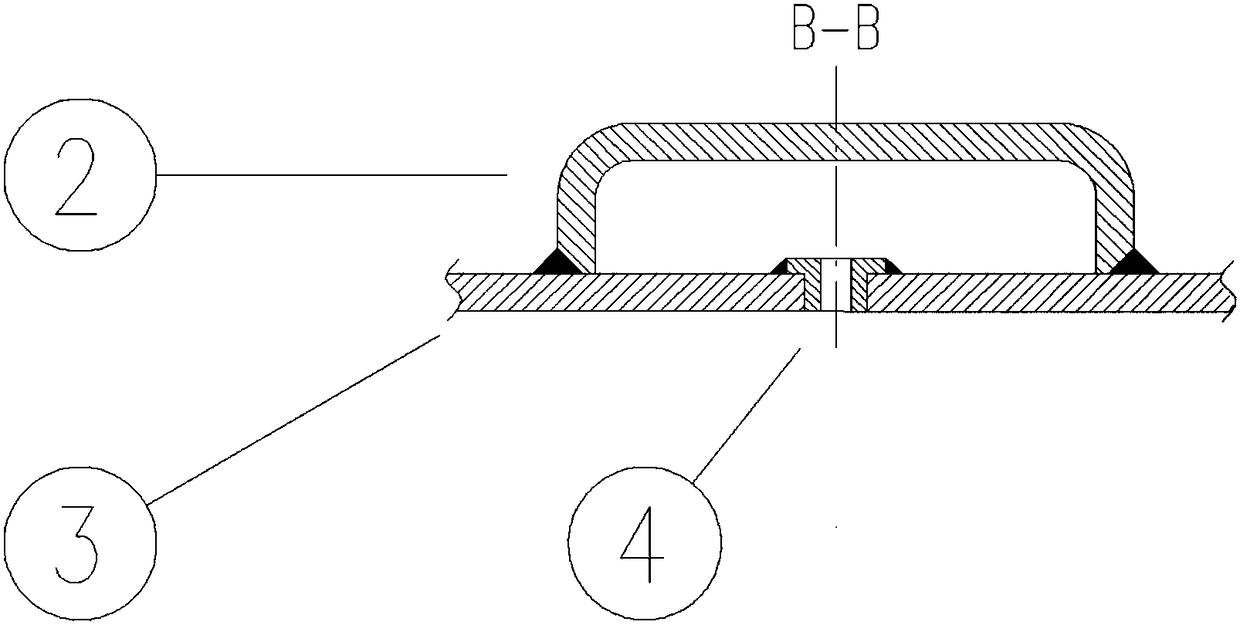

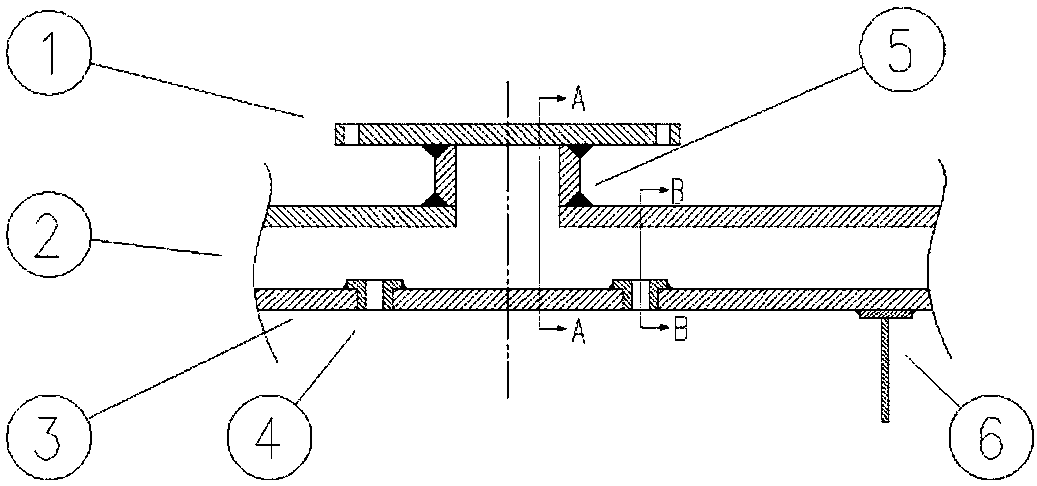

[0045] Taking the open-top container ship applying the marine gas Gap voltage regulator provided by the present invention as an example, the open-top container ship is Changhang Yangshan No. 2 400-box open-top container ship with a total length of 122.8m, a molded width of 18.8m, and a molded depth of 8.6m. m, a draft of 4.8m, and an operating speed of 9 knots. In November 2016, it was retrofitted with gas lubrication and drag reduction. In order to make the gas evenly and stably ejected from the jet hole, 5 independent pressure stabilizing chambers are built in the cabin, such as Figure 5 shown.

[0046] The control system of each independent pressure stabilizing chamber is as follows: Figure 6 shown. The plenum chamber is a narrow and long cavity arranged at the bottom of the cabin, which can be a narrow and long gas channel formed by welding stainless steel components on the inner side of the bottom plate of the ship. The corresponding plenum chamber is provided with je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com