Nozzle structure of combustion chamber in low heat value of gas turbine, and combustion method

A technology of gas turbine and combustion method, which is applied in the direction of combustion method, combustion chamber, continuous combustion chamber, etc., and can solve the problems such as the increase of flow resistance loss of the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

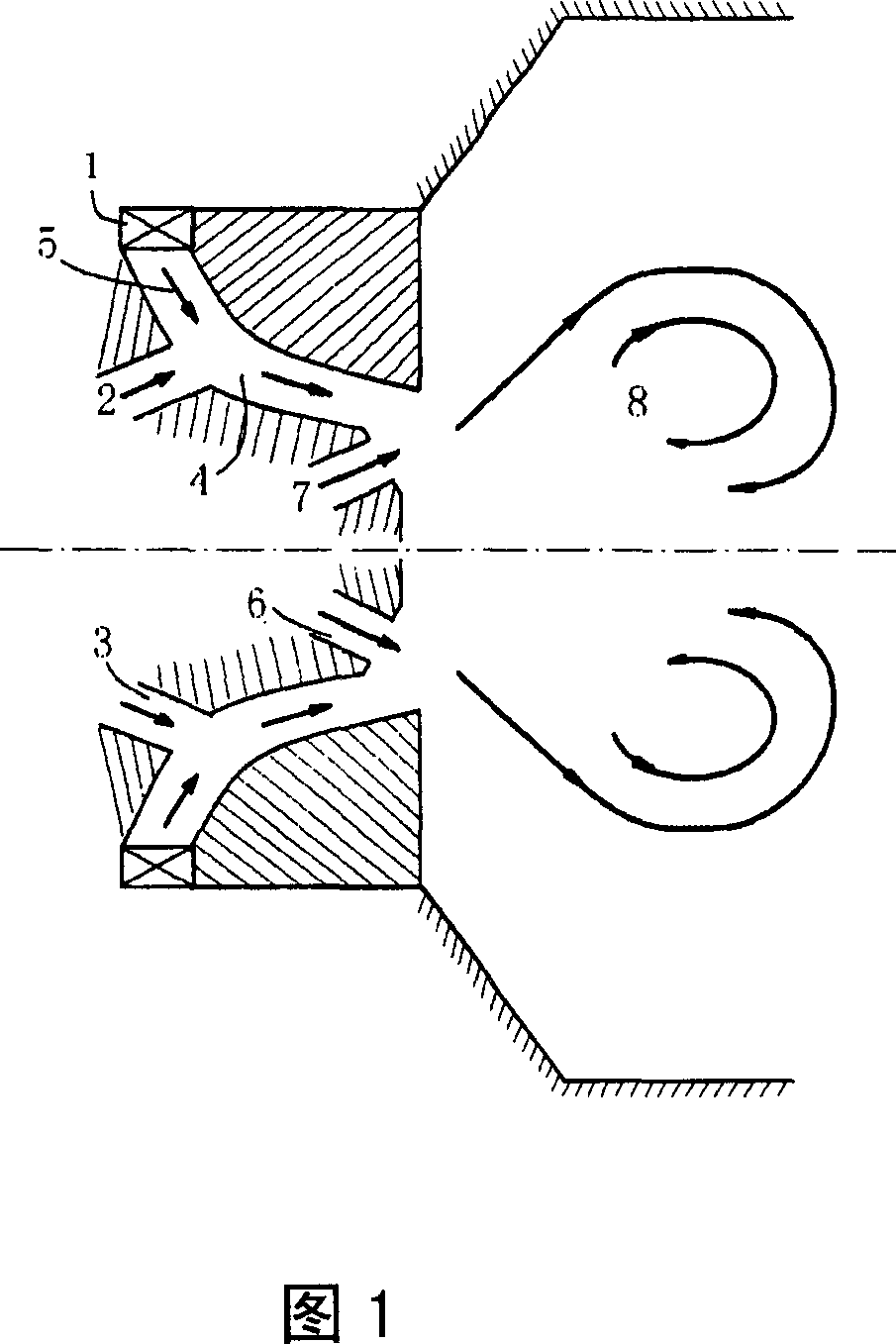

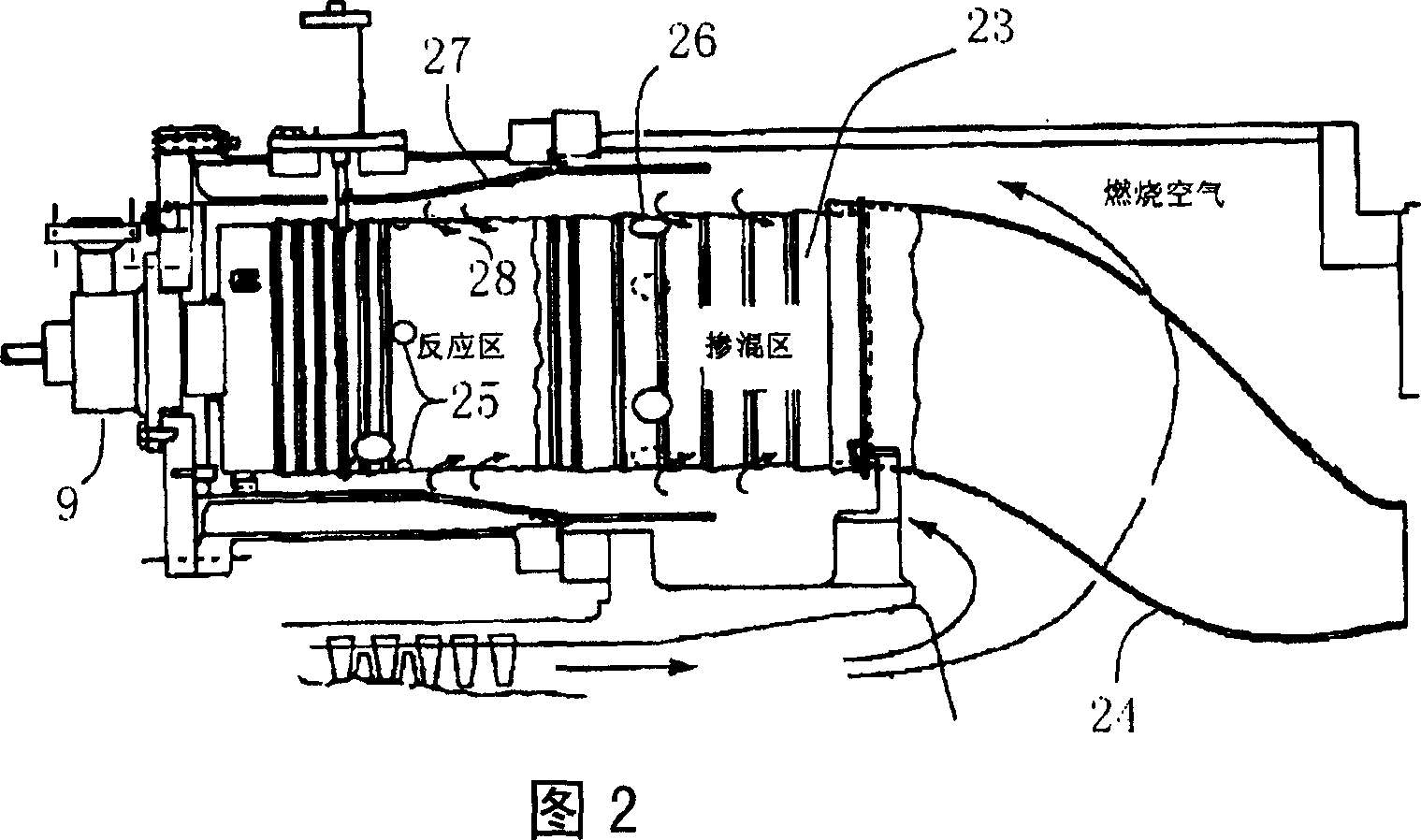

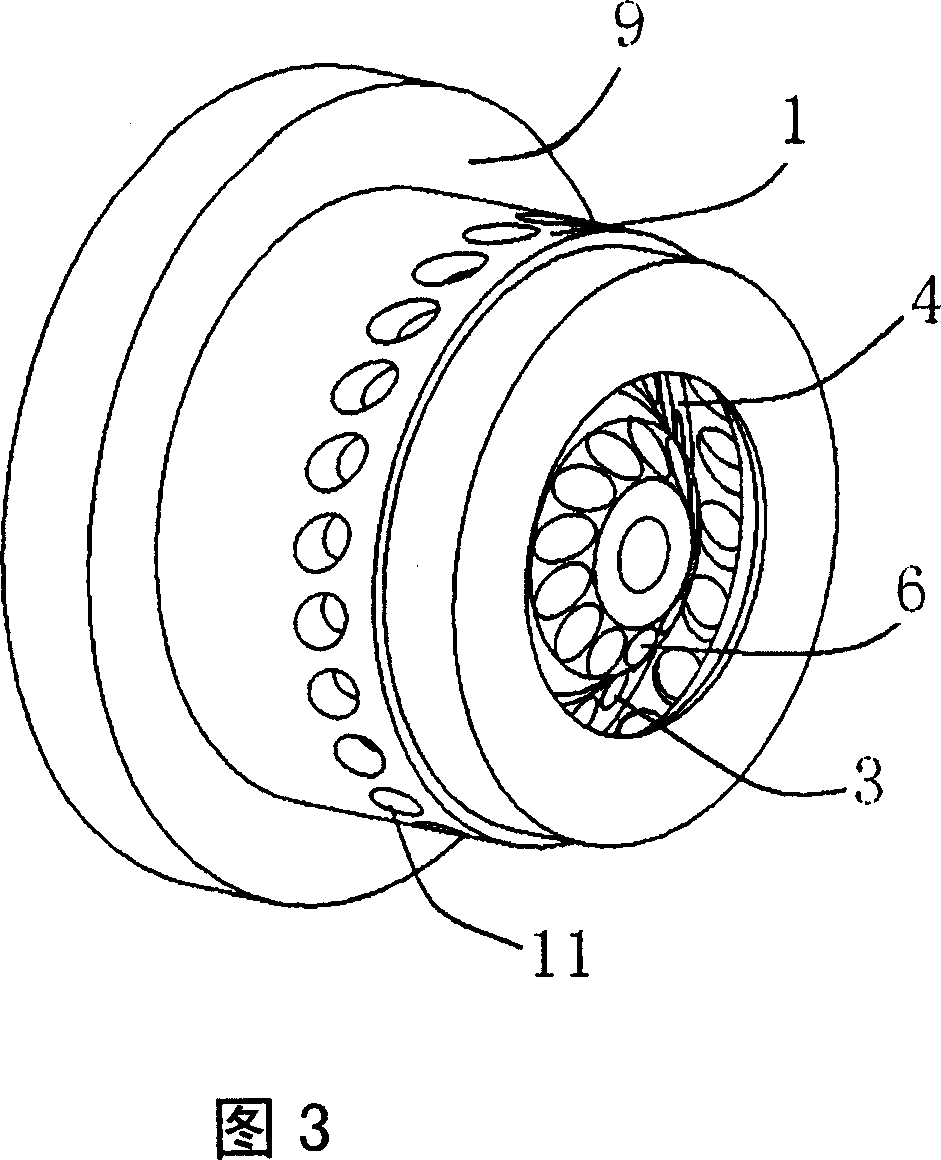

[0031] Fig. 1 is the design method and structural features of the low calorific value nozzle which adopts the combination of diffusion flame and partial premixing in the present invention. This new type of nozzle 9 adopts a radial air swirler 1, and the fuel jets are divided into two rows. The first row of fuel jets 2 directly injects into the swirler channel 4 through the first row of fuel swirl jet holes 3, and the same swirl flow The primary air 5 in the swirler channel 4 forms a rich premixed gas, and the second row of fuel swirl jet holes 6 is located at the outlet of the swirler channel 4, and its jet trajectory is directly injected into the combustion chamber. When the gas turbine works at a low load, the second row of fuel jets 7 forms a pure diffusion flame, which acts as a stable ignition point to maintain stable combustion. When the gas turbine works at high load, the first row of fuel jets 2 is mixed with the primary air 5 in the swirler channel 4, and the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com