Method for preparing carbon nano-tube by diffusion flame with stable limited area

A technology of diffusing flame and carbon nanotubes, which is applied in the field of preparing carbon nanotubes, and can solve problems such as poor repeatability, difficult stable state, unfavorable flame method application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

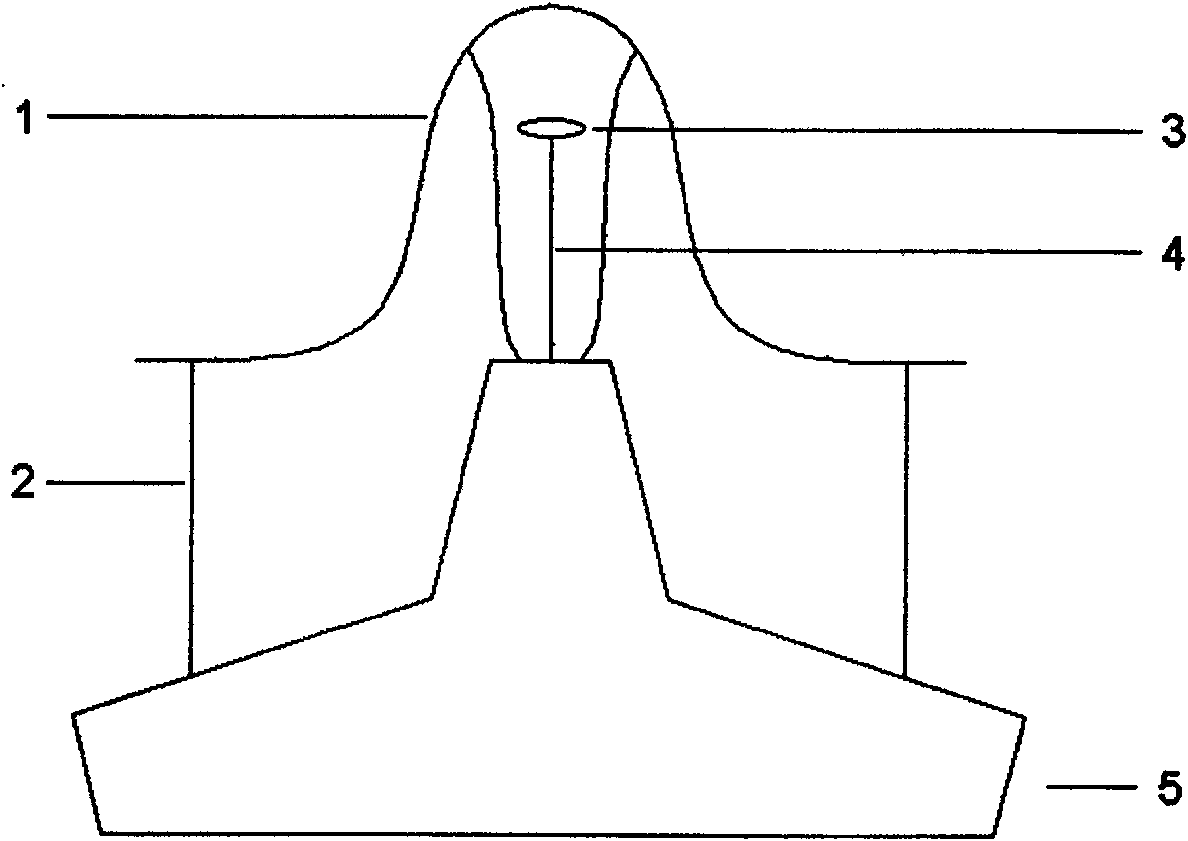

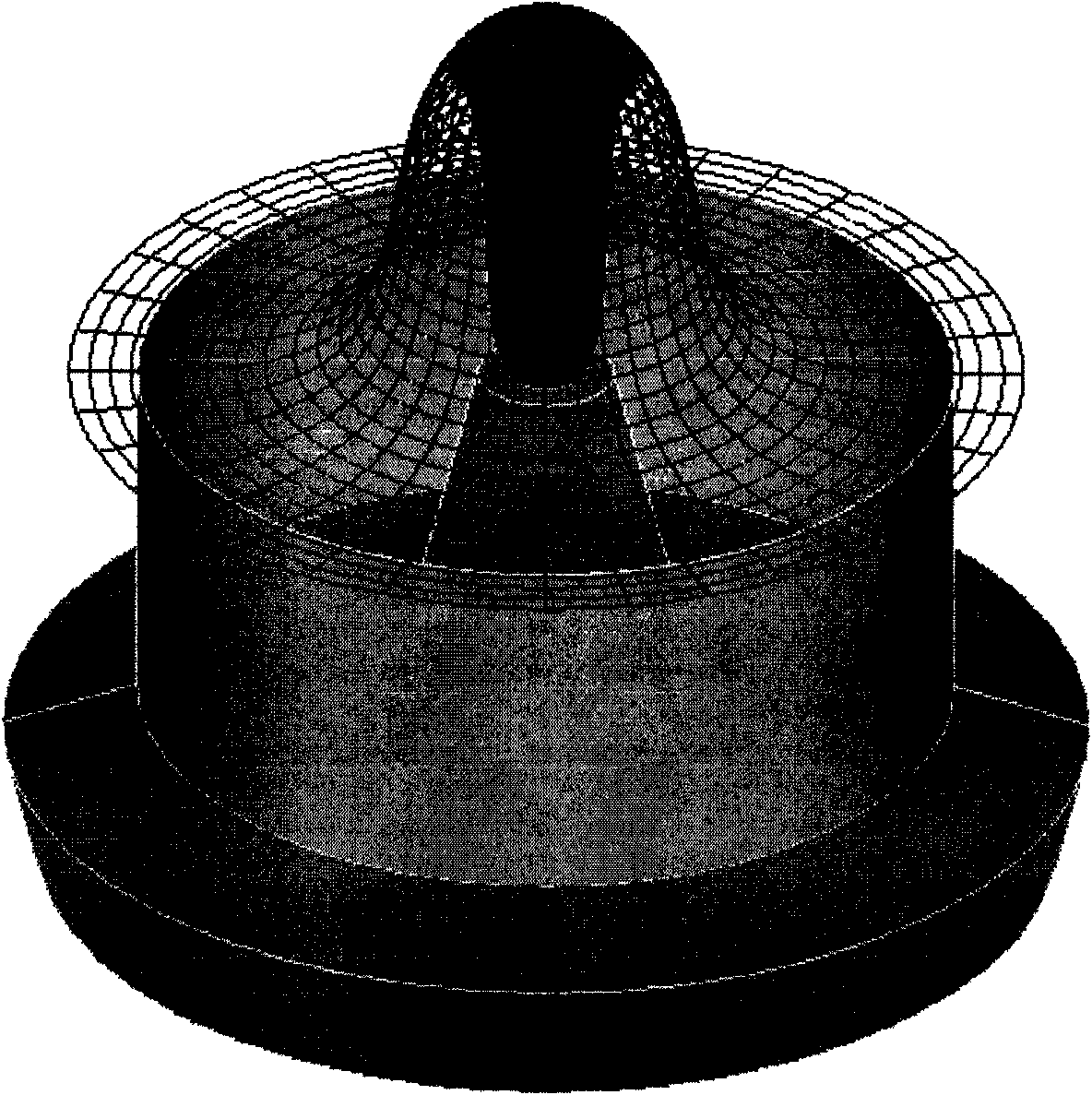

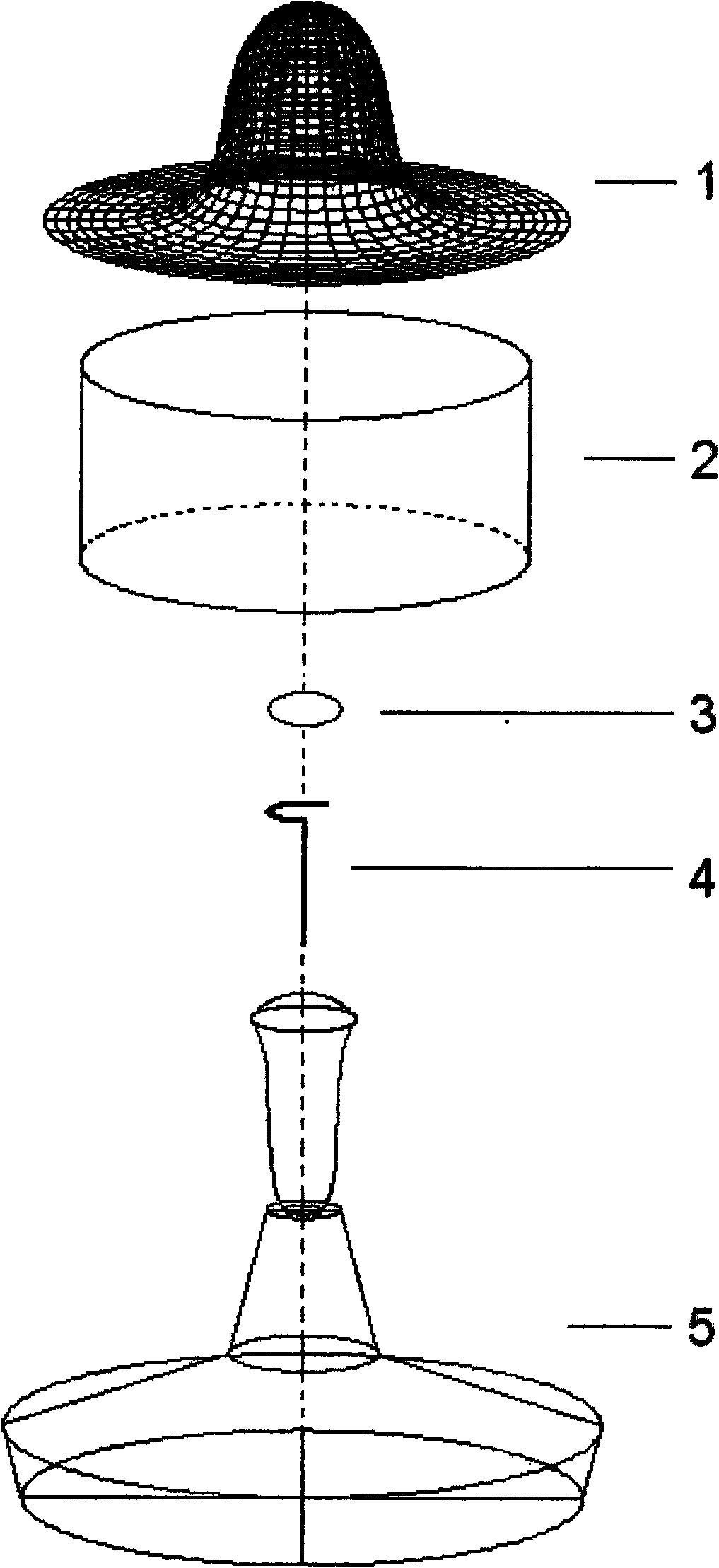

Method used

Image

Examples

Embodiment 1

[0027] Take 0.29g of analytically pure nickel nitrate and dissolve it in 10ml of absolute ethanol to form a 0.1mol / l nickel nitrate solution and apply it on a clean copper substrate and let it dry naturally. Insert the bracket into the wick of an alcohol lamp, put the dry copper substrate on the bracket, put on the support ring, light the alcohol lamp filled with ethanol, cover with a flame stabilization cover, burn for 10 minutes, extinguish the flame, and obtain the product. The morphology of the product was characterized by scanning electron microscopy. Figure 4 It can be seen that its morphology is fibrous, with a single shape and a diameter of about 40-50nm; Figure 5 Display: Under a high-resolution transmission electron microscope, it can be seen that it is a multi-walled carbon nanotube whose crystal lattice is arranged in a fishbone shape.

Embodiment 2

[0029] Take 0.29g of analytically pure nickel nitrate and dissolve it in 10ml of absolute ethanol to form a 0.1mol / l nickel nitrate solution and apply it on a clean copper substrate and let it dry naturally. Insert the bracket into the wick of the alcohol lamp, put the dry copper substrate on the bracket, put on the support ring, light the alcohol lamp filled with methanol, cover with the flame stabilization cover, burn for 10 minutes, extinguish the flame, and obtain carbon nanotubes.

Embodiment 3

[0031] Take 0.29g of analytically pure nickel nitrate and dissolve it in 10ml of absolute ethanol to form a 0.1mol / l nickel nitrate solution and apply it on a clean copper substrate and let it dry naturally. Insert the bracket into the wick of the alcohol lamp, put the dry copper substrate on the bracket, put on the support ring, light the alcohol lamp filled with acetone, cover with the flame stabilization cover, burn for 10 minutes, extinguish the flame, and obtain carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com