Particle sensor calibration system and measuring method

A particle sensor and calibration system technology, which is applied in the field of vehicle exhaust emission control, can solve the problems of lack of accurate and effective particle sensor calibration devices and measurement methods, and achieve the effect of convenient and reliable recording of instantaneous soot concentration, easy implementation, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

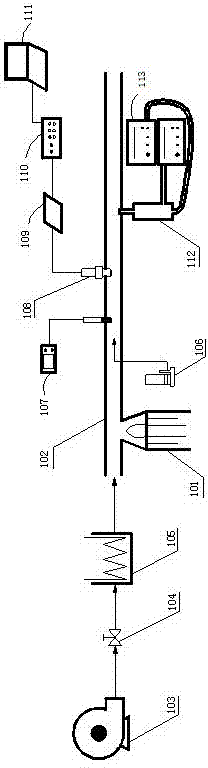

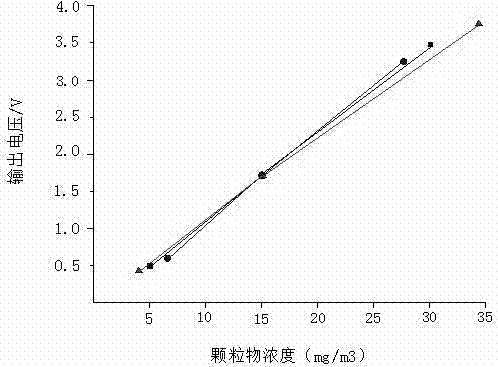

[0019] In the particulate matter sensor calibration system and measurement method of the present invention, the fuel is passed into the back-diffusion flame burner 101, the upper port of the burner is connected with the first lower hole of the exhaust pipe 102, and the mixed gas is ignited to burn to generate stable soot; The compressor 103 blows in a stable amount of air, adjusts the intake air volume through the pressure regulating valve 104, and then heats up through the heater 105, setting the heating rate at 20°C / min until the temperature sensor 107 outputs the final heating temperature to 300°C And maintain, the air after heating enters exhaust pipe and is used for diluting the soot that combustion produces; Regulate pressure regulating valve 104, make the intake flow of flowmeter 106 be 3kg / min; Output the voltage signal after conversion, the signal value is collected by the A / D converter 110, and the voltage value is read out by the computer 111 as 1.7 V, and the s...

Embodiment 2

[0021] On the basis of the method in Example 1, change the heating rate to 10°C / min, and the temperature sensor outputs the final heating temperature to 200°C. When the measured voltage value is 0.4 V, the corresponding particle concentration is 4 mg / m3; change the heating rate to 30°C / min, the temperature sensor outputs the final heating temperature to 400°C, and the corresponding particle concentration is 35 mg / m3 when the measured voltage value is 3.8 V; record the voltage values corresponding to different particle concentrations under the same conditions and change the temperature, and draw Calibration curve 2, a different calibration curve can be obtained, see figure 2 triangular curve.

Embodiment 3

[0023] On the basis of the method in Example 1, under the same circumstances, by adjusting the pressure regulating valve to change different intake flow rates, when the intake flow rate is adjusted to 2kg / min, the corresponding particle concentration when the measured voltage value is 0.6 V is 6mg / min. m3; when the intake air flow rate is adjusted to 4kg / min, the corresponding particle concentration when the measured voltage value is 3.2 V is 28 mg / m3. Record the voltage values corresponding to different particle concentrations by changing the intake flow rate under the same conditions, and draw the calibration curve 3 to obtain another different calibration curve. For details, see figure 2 circular curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com