Combustion device and method for a dual-fuel engine based on a dual-needle valve injector

A dual-fuel engine and combustion device technology, which is applied to combustion engines, machines/engines, fuel injection devices, etc., can solve the problem that the stability and fuel economy of the engine need to be improved, the stability of the engine is affected, and the output power of the engine is reduced. problem, to achieve the effect of being conducive to flame propagation, fast and flexible switching, and improving the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings:

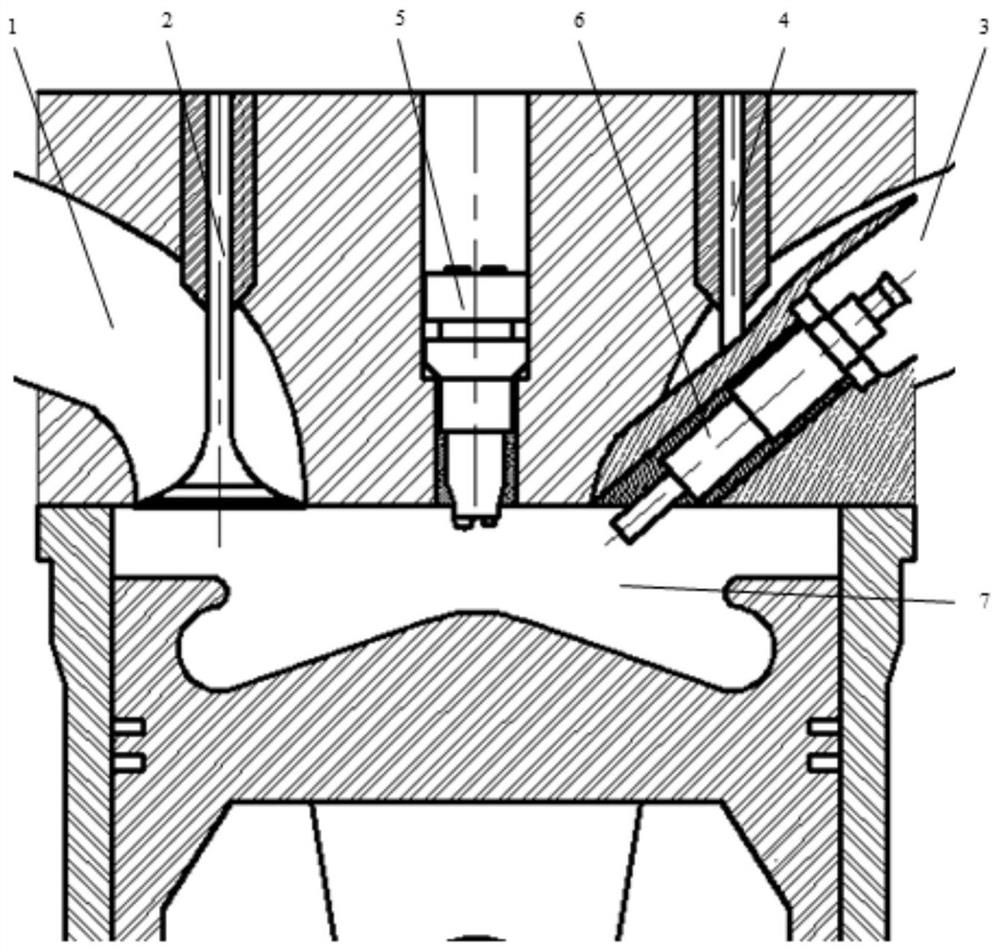

[0035] figure 1 It is a structural schematic diagram of a dual-fuel engine combustion device based on a dual-needle valve injector;

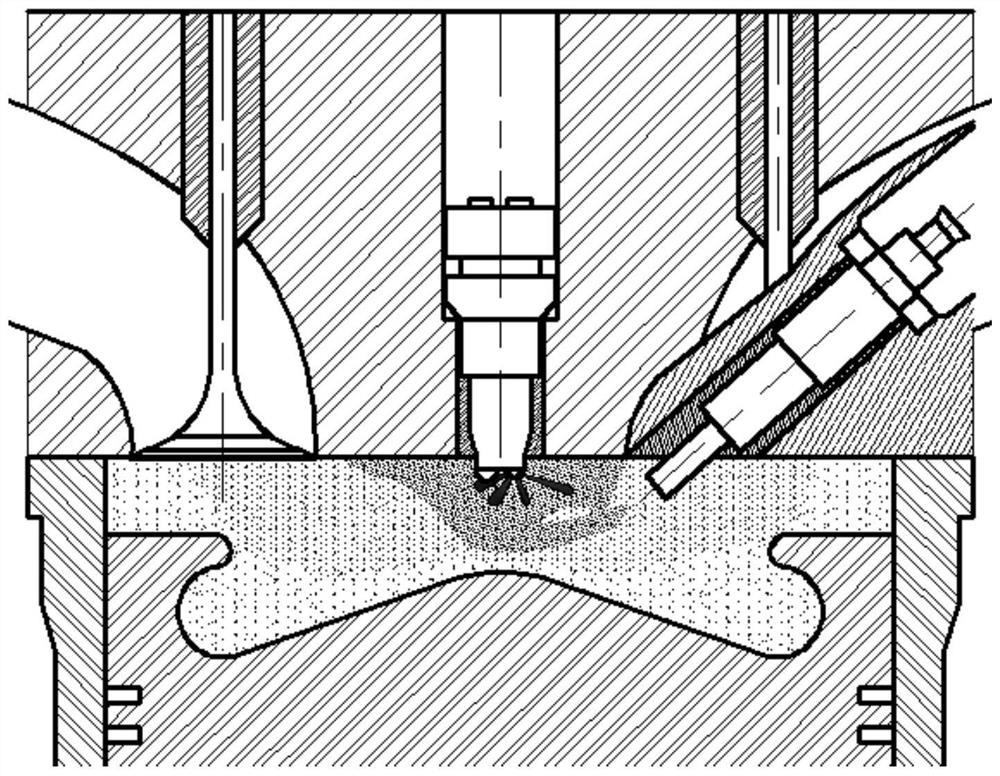

[0036] figure 2 It is a schematic diagram of the working state of the double-needle valve injector before the piston compression top dead center in the gas mode of the present invention and a distribution diagram of the concentration of the combustible mixture in the cylinder;

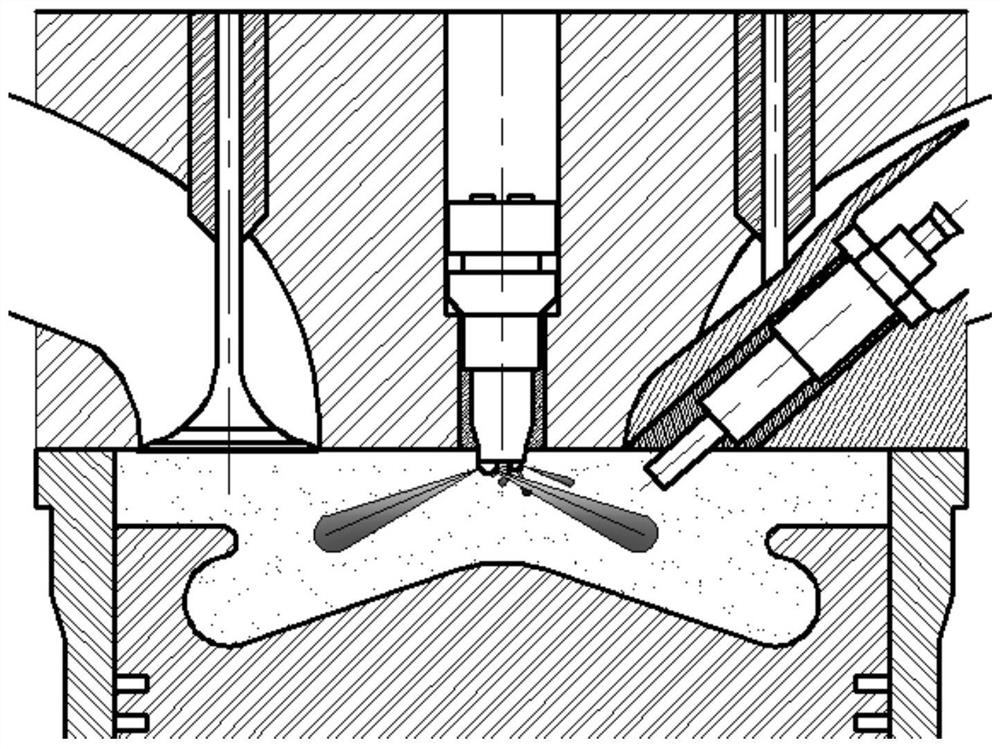

[0037] image 3 It is a schematic diagram of the working state of the double-needle valve injector before the piston compression top dead center in the diesel mode of the present invention;

[0038] Figure 4 It is a schematic diagram of the nozzle part of the double-needle valve fuel injector of the present invention;

[0039] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com