Enhanced discharge igniter for marine large-bore gas engine

A technology of gas engine and large cylinder diameter, which is applied in the direction of engine ignition, spark ignition controller, engine components, etc. It can solve the problems that cannot meet the high energy and high reliability requirements of marine gas engines, and achieve the improvement of ignition stability and discharge The effect of strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

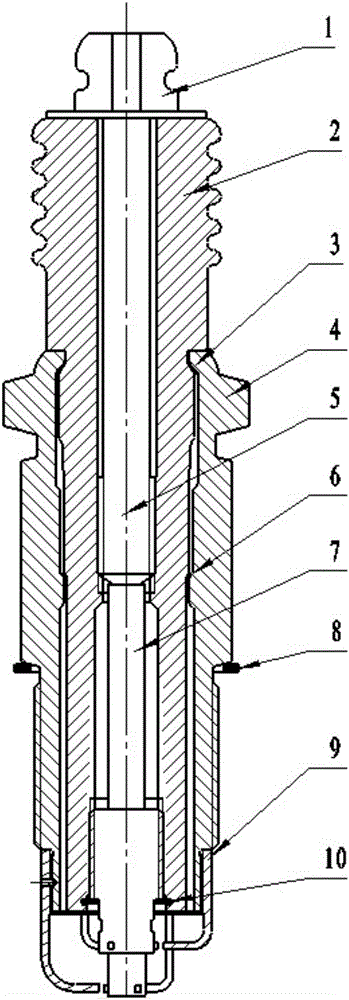

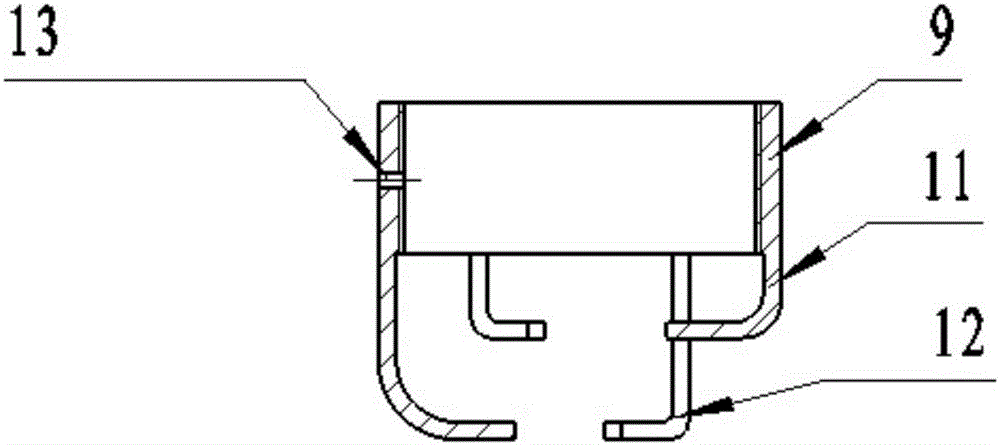

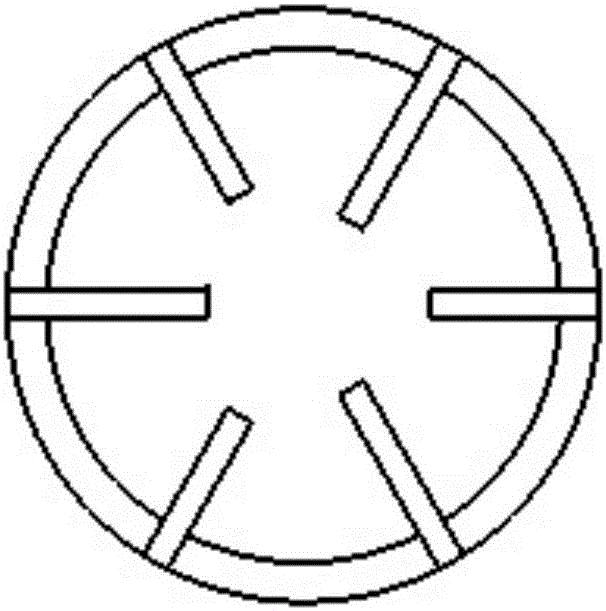

[0019] combine figure 1 -3. The enhanced discharge igniter for a marine large-bore gas engine of the present invention includes a wire nut 1, an insulator 2, an upper gasket 3, a metal shell 4, a wire screw 5, a lower gasket 6, a center electrode 7, a sealing gasket 8, The side electrode 9 and the open retaining spring 10 constitute. The metal shell 4 and the center electrode 7 are separated by the insulator 2. There are two threads on the outer surface of the metal shell 4. One thread is used to install the enhanced discharge ignition on the engine cylinder head, and the other thread is used to fix the side electrode. 9. The side electrodes 9 and the metal shell 4 are independent of each other, which can ensure the maintainability of the electrodes. The side surface of the side electrode 9 is processed with a positioning hole 13 with an internal thread, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com