Pulverized coal jet flow midstream and downstream combustion organization method in tangent circle pulverized coal combustion boiler

A technology of pulverized coal combustion and pulverized coal burner, which is applied in the fields of boiler pulverized coal combustion for power generation and boiler pulverized coal combustion, can solve the problems of boiler pulverized coal combustion efficiency decline, furnace coking, high temperature corrosion of water wall, etc., and achieves improved ignition stability. The effect of improving the combustion capacity, improving the combustion rate of pulverized coal, and reducing the generation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

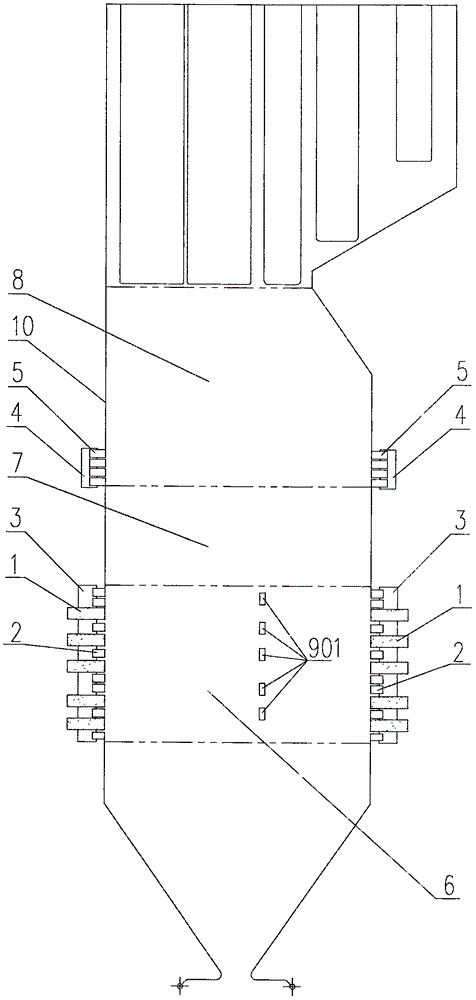

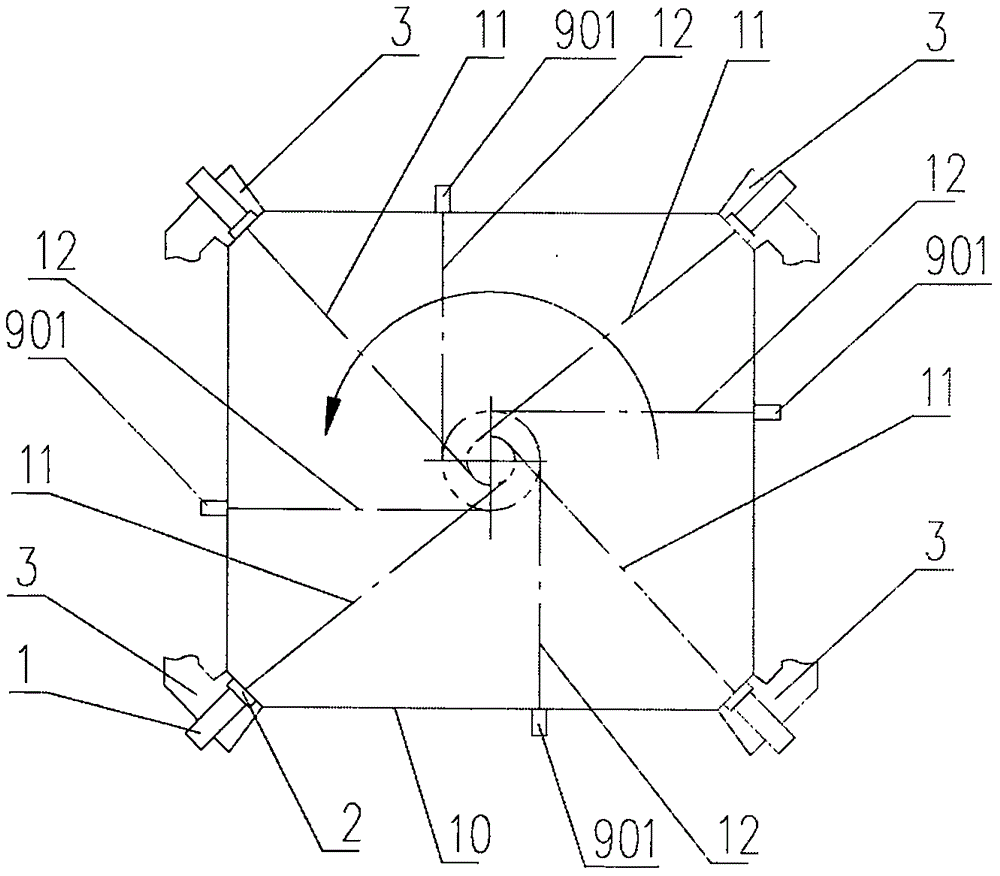

[0046] Such as figure 1 , image 3 As shown, it is a schematic diagram of the furnace combustion system of the middle and downstream combustion organization of the pulverized coal jet in a four-corner tangential pulverized coal combustion boiler using a direct blowing pulverization system and a separate overfire air system. In this example, the boiler is a 300MW four-corner tangential coal pulverized combustion boiler, the pulverizing system adopts a medium-speed mill positive pressure direct blowing system, the coal quality is mixed combustion of sub-bituminous coal and lean coal, and the coal quality of the furnace is dry and ash-free. The volatile matter is about 23%, the low calorific value is about 21MJ / kg, and the ash melting point ST is 1210°C. The original combustion system organization of the boiler adopts the low-nitrogen combustion technology with separated overfire air.

[0047] Such as figure 1 As shown, the overall arrangement form of all furnace low-nitrogen c...

specific Embodiment approach 2

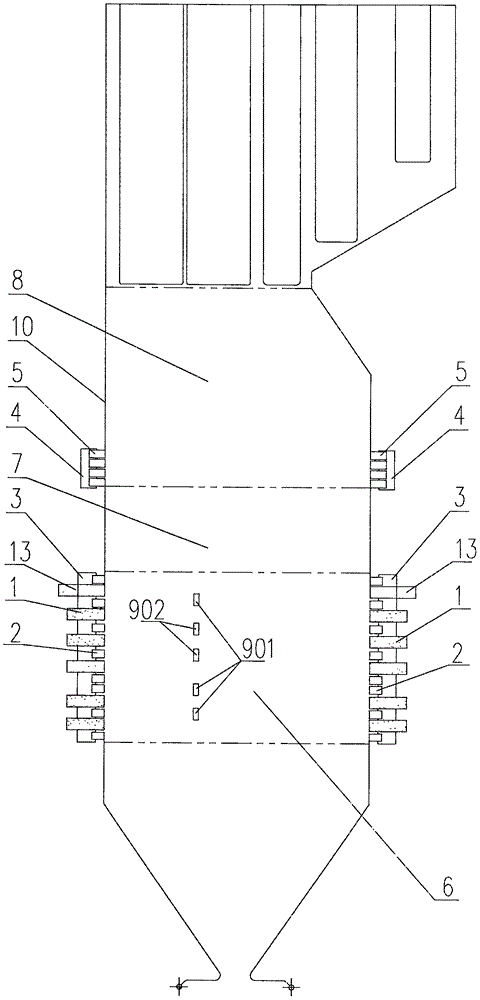

[0061] Such as figure 2 , Figure 4 As shown, it is a schematic diagram of the furnace combustion system of the middle and downstream combustion organization of the pulverized coal jet in a four-wall tangential pulverized coal combustion boiler with a mid-storage hot air powder feeding system and a separate overfire air system. In this example, the boiler is a 350MW four-wall tangential coal pulverized combustion boiler. The volatile content of the dry ash-free base is about 14%, the low calorific value is about 20MJ / kg, and the ash melting point ST is 1300°C. The original combustion system organization of the boiler adopts the low-nitrogen combustion technology with separated overfire air.

[0062] Such as figure 2 As shown, the overall arrangement form of all furnace low-nitrogen combustion systems with separate overfire air systems is the same, the furnace combustion is divided into three areas along the furnace height direction: the lower part is the main combustion ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com