Plasma Duty Flame Igniter Based on Aeroengine Afterburner

A technology of afterburner and aero-engine, applied in the field of ion flame igniter on duty, which can solve problems such as harsh working environment, complex structure, unfavorable rapid ignition, etc., to widen the ignition boundary, improve combustion efficiency, and shorten ignition delay time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

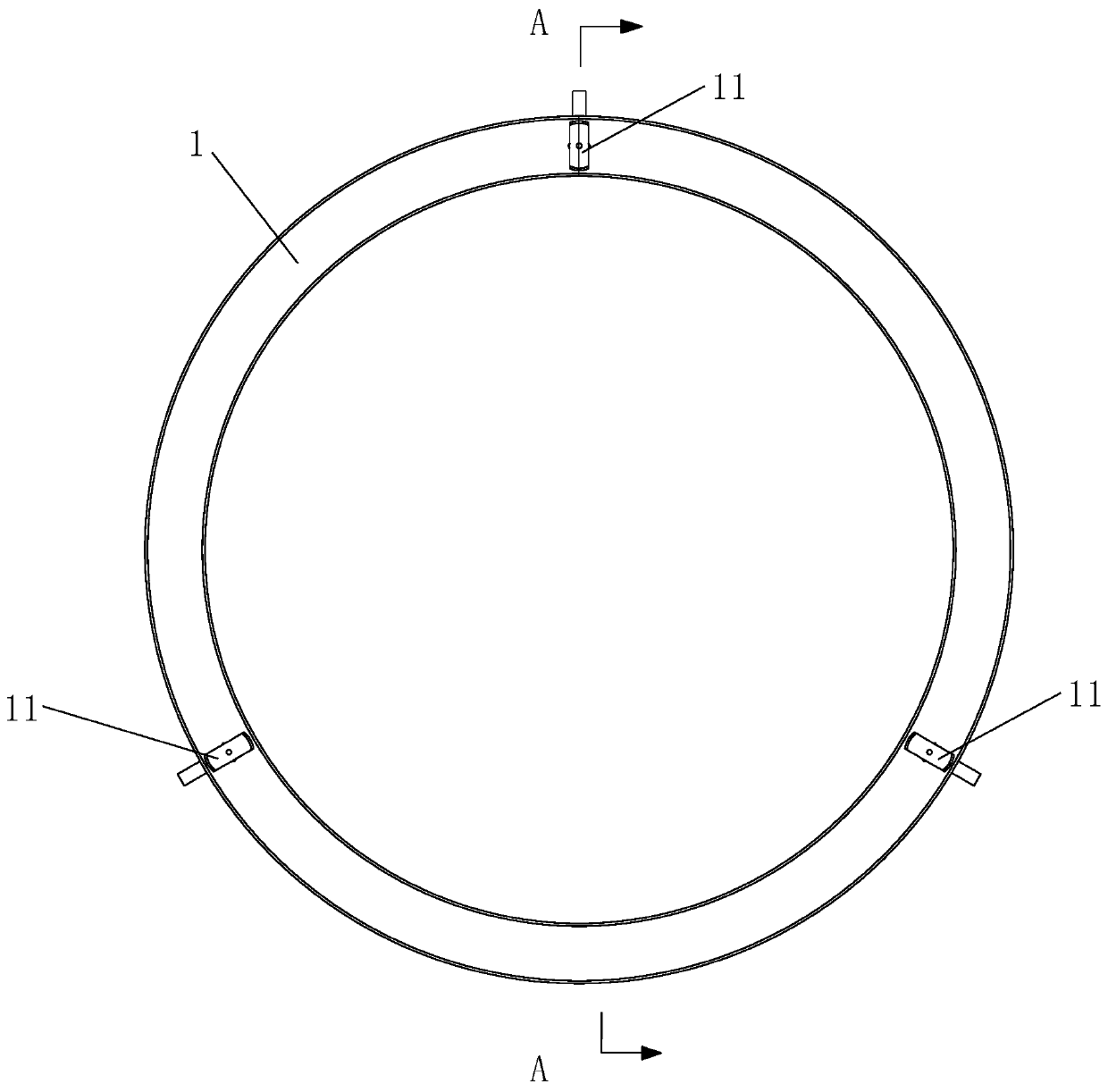

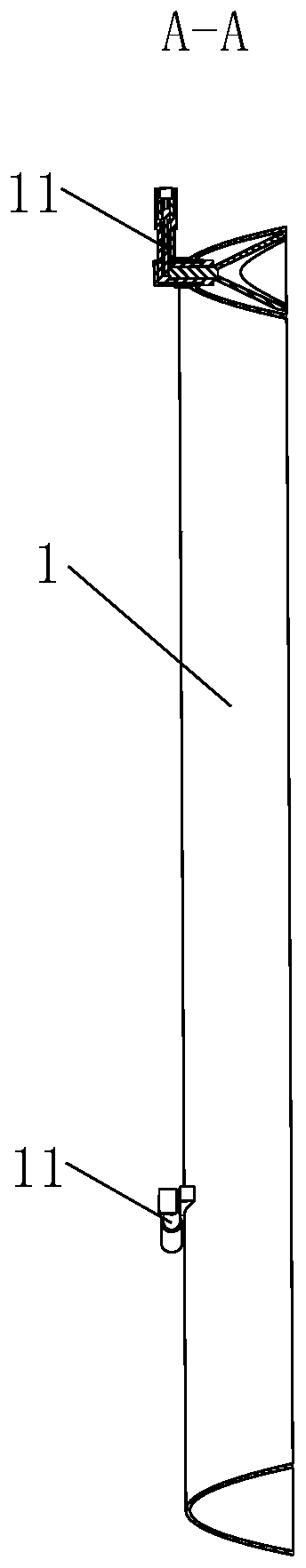

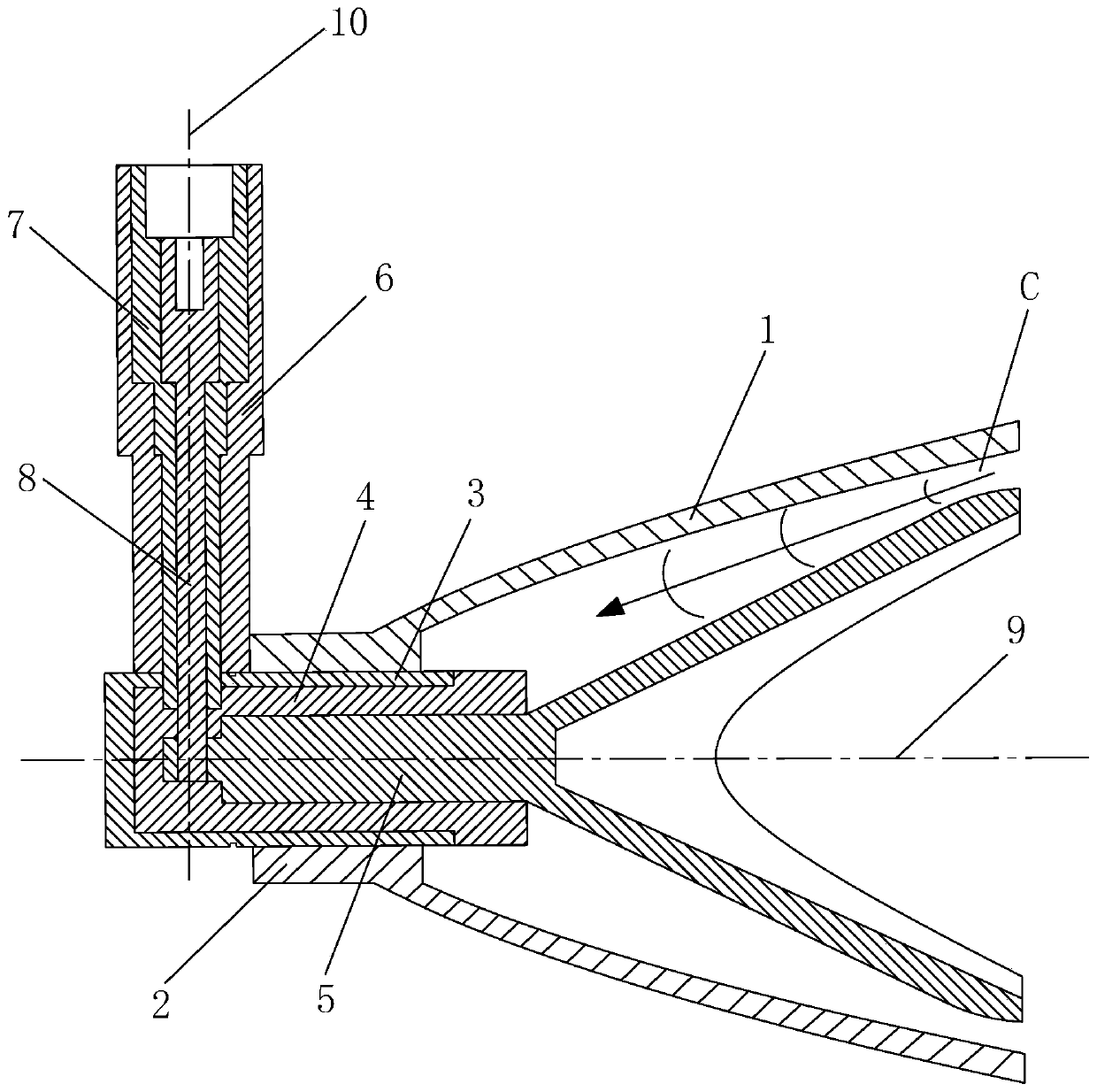

[0044] Such as Figure 1 to Figure 3 As shown, the present invention includes a flame stabilizer 1 and an embedded cathode assembly 11 installed on the flame stabilizer 1, the number of the embedded cathode assembly 11 is at least one, and the embedded cathode assembly 11 includes a connection Sleeve 2, cathode housing 3, transverse insulating tube 4, Y-shaped cathode 5, guide rod housing 6, longitudinal insulating tube 7 and energized guide rod 8, the connecting sleeve 2 is sleeved on the right side of the cathode housing 3 and the inner wall of the connecting sleeve 2 is screwed to the outer wall of the cathode casing 3, the right end of the connecting sleeve 2 is welded to the small end of the flame stabilizer 1, and the left middle part of the transverse insulating tube 4 is arranged on the cathode In the housing 3, the right end of the transverse insulating tube 4 is located outside the cathode housing 3, the closed end of the Y-shaped cathode 5 is arranged in the transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com