Enhanced graded low NOx pulverized coal burner

A pulverized coal burner and pulverized coal technology are used in burners, burners for burning powder fuel, combustion methods, etc., which can solve the problems of combustion delay and fly ash combustibles, and achieve delayed combustion and good ignition stability. , Improve the effect of swirl strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

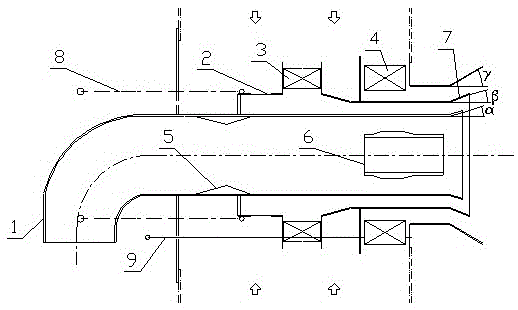

[0013] The enhanced graded low NOx pulverized coal burner of the present invention is mainly composed of primary air channel 1, secondary air channel 2 in direct current, secondary air channel 3 in swirl flow, secondary air channel 4 outside swirl flow, and pulverized coal flow equalizer 5. Composition of pulverized coal separator 6; a pulverized coal flow equalizer 5 is installed on the inlet side of the straight pipe section of the primary air channel 1, and a pulverized coal separator 6 is installed on the outlet side, and the periphery of the primary air channel 1 is equipped with a secondary air flow in the direct current. Channel 2, the outer wall of the direct current internal secondary air channel 2 is provided with a swirl internal secondary air channel 3 that converges in the same channel and sprays into the furnace, and the outlet of the primary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com