Tiny-oil ignition device of pulverized coal burner

A pulverized coal burner, micro-oil ignition technology, applied in the direction of combustion ignition, burner, burner burning powder fuel, etc., can solve the problems of high investment cost, high energy consumption, etc., to reduce fuel consumption, reduce Heat dissipation loss, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

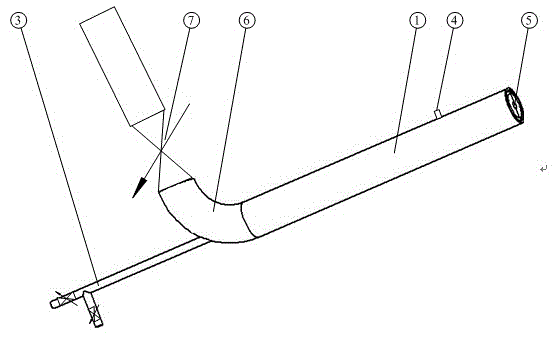

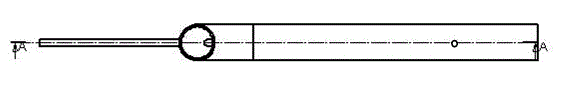

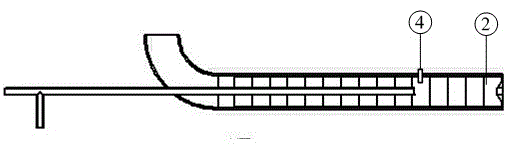

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a micro-oil ignition device for a pulverized coal burner is composed of a circular igniter passage pipe 1 with a regulating valve 7 lined with a high-temperature refractory ceramic sheet 2, an igniter 4 extending into the interior of the igniter passage pipe, and a The retractable ignition oil gun 3 coaxial with the igniter passage tube, the high-temperature refractory ceramic blunt body 5 located at the outlet end of the igniter passage pipe, etc. are installed and connected. One end of the ignition oil gun extends into the igniter passage tube, the igniter is arranged on the tube wall of the igniter passage pipe and extends into the igniter passage tube, the igniter is close to the outlet end of the ignition oil gun arranged in the igniter passage pipe, and the high temperature The refractory ceramic blunt body is arranged at the outlet end of the igniter passage tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com