Low emission vehicle

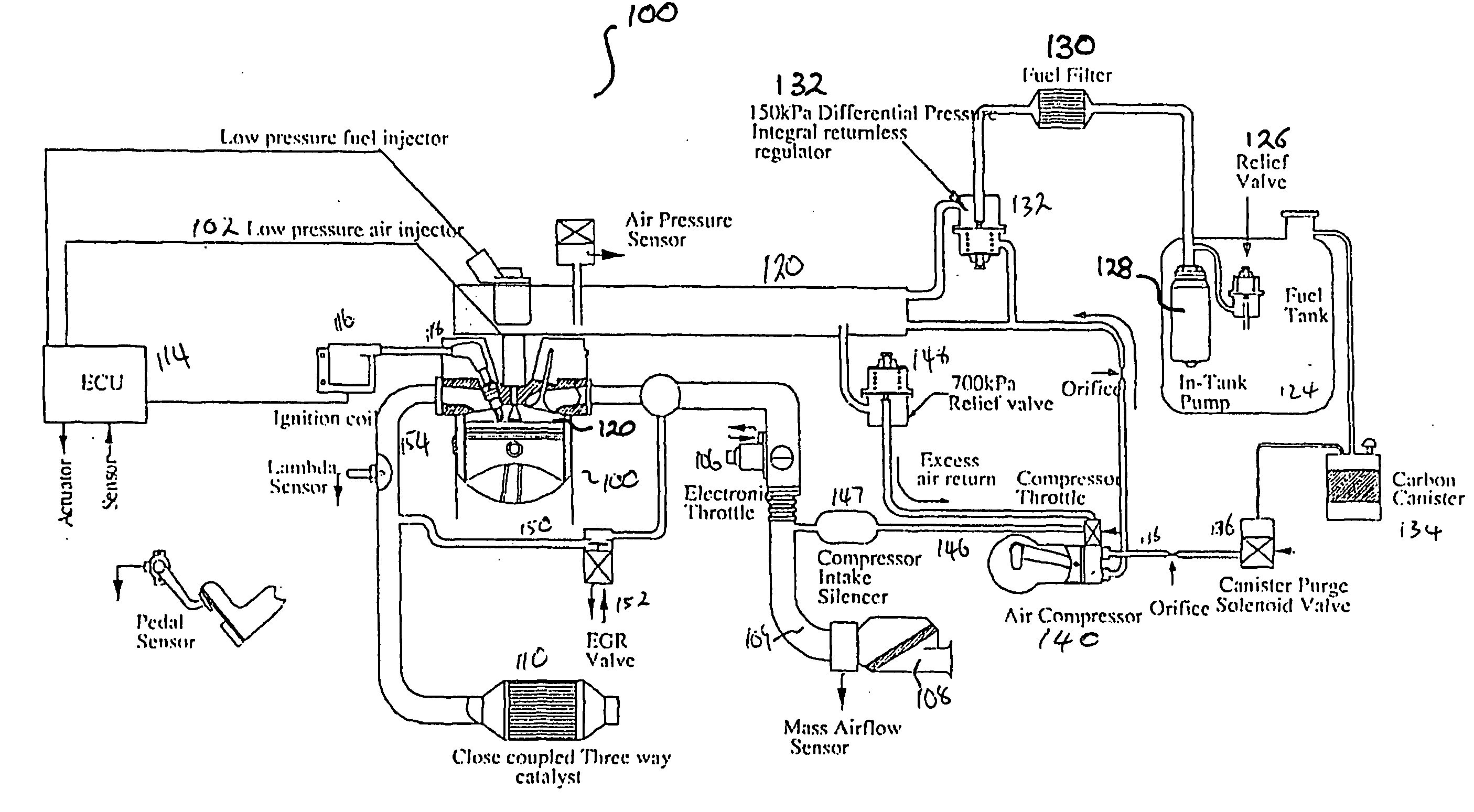

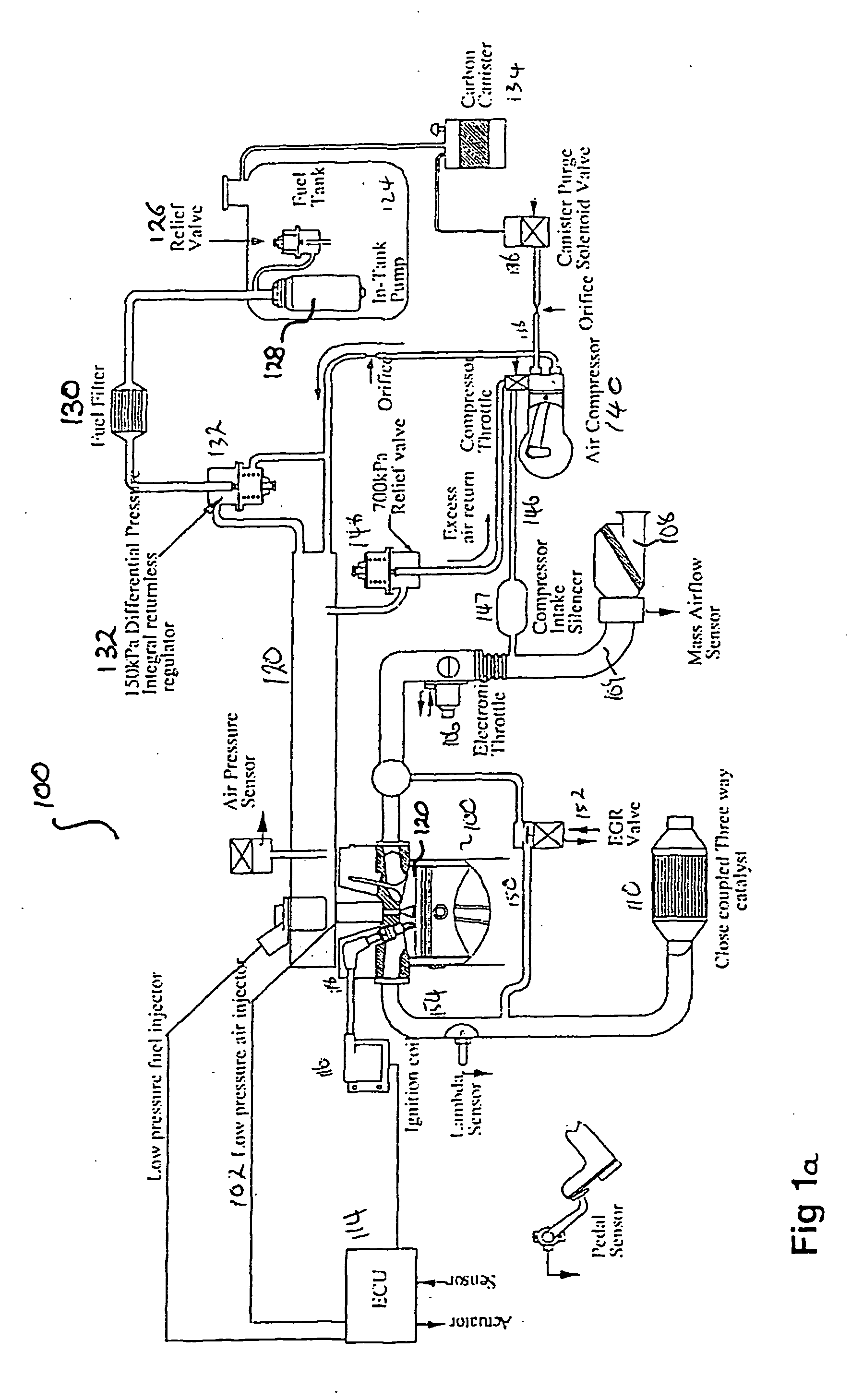

a low-emission vehicle and low-emission technology, applied in the direction of machines/engines, electrical control, separation processes, etc., can solve the problems of increasing fuel consumption, increasing fuel consumption, and most mpi (manifold port injection) vehicles suffering fuel consumption penalties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

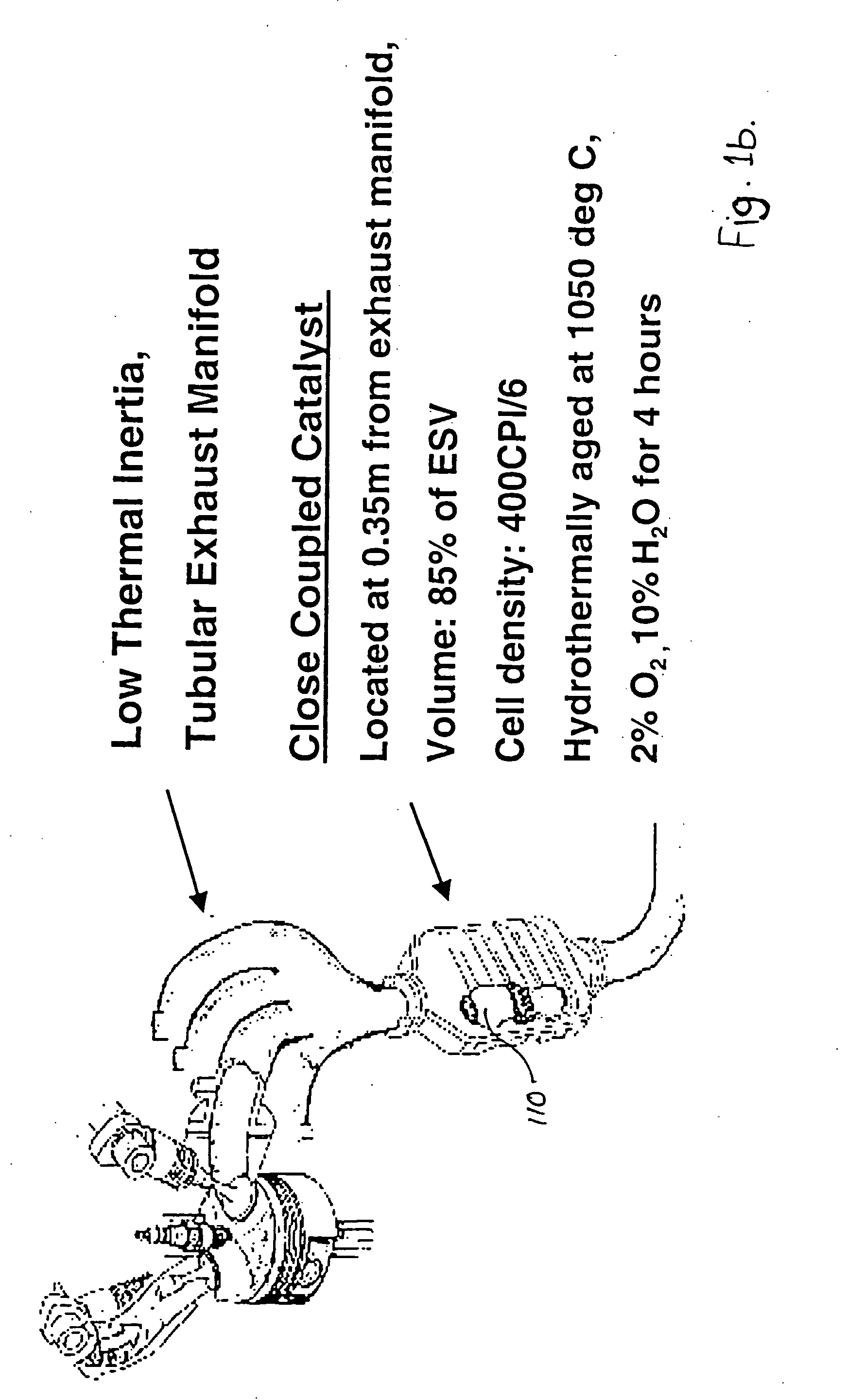

[0031] The present embodiments provide direct injection lean burn and direct injection stratified charge internal combustion engines that operate with lean air fuel ratios across at least part of the MVEG-B drive cycle and that comply with Euro IV emissions requirements without the need for an exhaust system with NOx storage capability. One preferred embodiment utilises a spray guided direct injection fuel system.

[0032] Emissions legislation is being introduced around the world that requires engine and vehicle manufacturers to reduce the emissions produced by various types of vehicles. An example of such legislation that is applicable to Europe is commonly referred to as the Euro III and Euro IV emissions targets and should be well known to those skilled in the relevant art.

[0033] The Euro III and Euro IV emissions targets for passenger vehicles powered only by gasoline in respect of HC, CO and NOx emissions are:

1 EC 2000 EC 2005 TEST EMISSIONS UNIT (EURO III) (EURO IV) Rev. HC g / km...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com