Production line for Li-Mn button battery

A button battery and production line technology, which is applied to primary batteries, electrochemical generators, non-aqueous electrolyte batteries, etc., can solve the problems of lack of battery quality, poor production consistency, and low efficiency, and achieve the goal of improving production efficiency and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

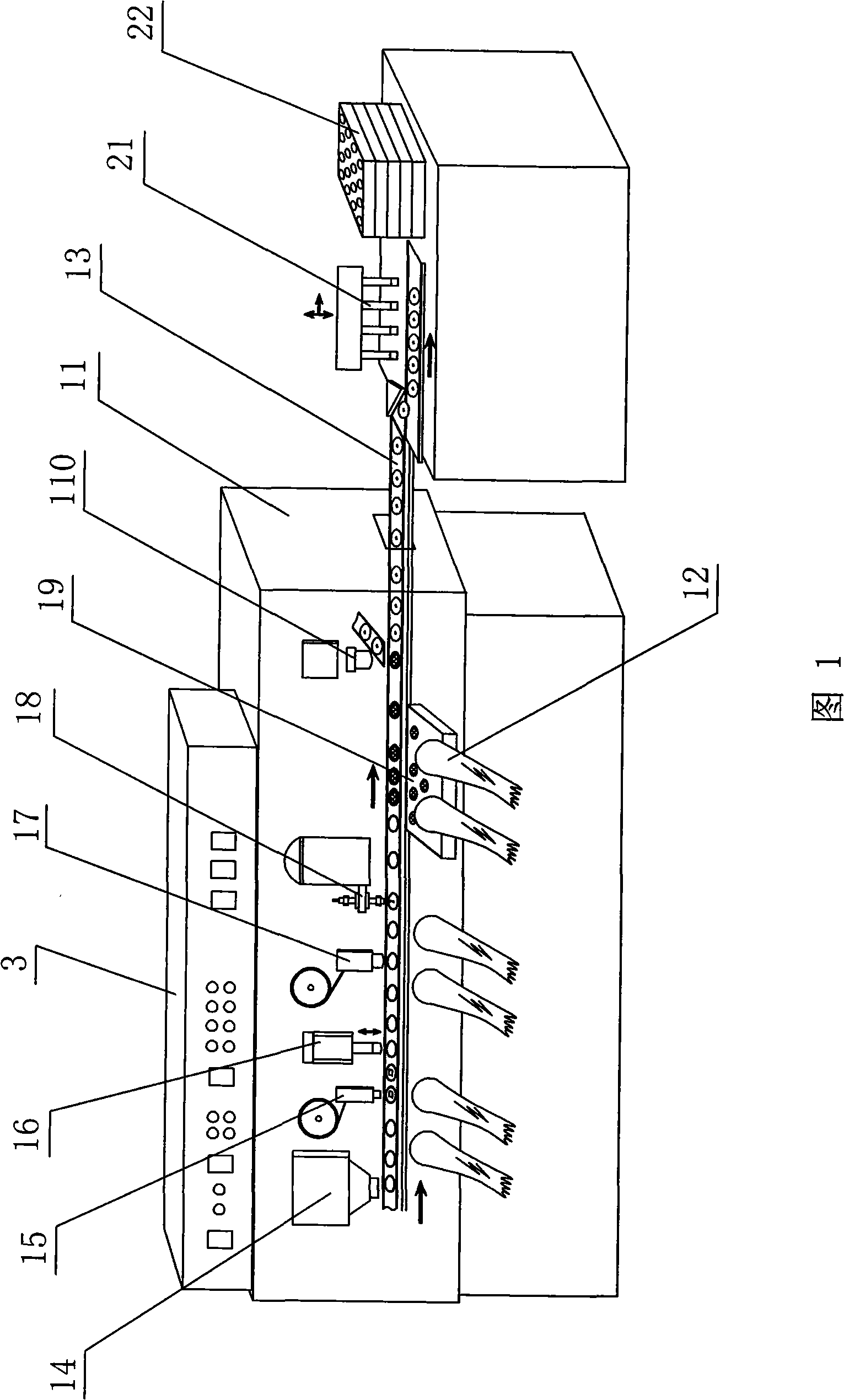

[0011] The lithium-manganese button battery production line shown in Figure 1 includes three parts: an assembly line, a battery boxing station, and electrical equipment 3. The entire battery assembly line is located in a transparent sealing cover 11, and the two sides of the sealing cover 11 are provided with Operate the hand hole, and the hole is along the upper cover of the rubber glove 12. The assembly line includes a revolving conveyor belt 13 and assembly equipment arranged on both sides of the conveyor belt 13. The assembly equipment is sequentially along the conveying direction of the conveyor belt 13. Vibrating hoppers 14, Lithium sheet inserting machine 15, lithium sheet punching machine 16, diaphragm inserting machine 17, liquid dripping machine 18, positive electrode sheet inserting machine 19, and positive electrode shell pressing and sealing machine 110, where the conveyor belt 13 passes through the head end of the isolation cover 11. The outlet extends onto the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com