Deviation rectifying device of gypsum board production line

A deviation correction device and production line technology, applied in ceramic molding workshops, auxiliary molding equipment, ceramic molding machines, etc., can solve problems affecting production quality, product quality, and work efficiency, and achieve high control accuracy and automation. Production efficiency and product quality, to achieve reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

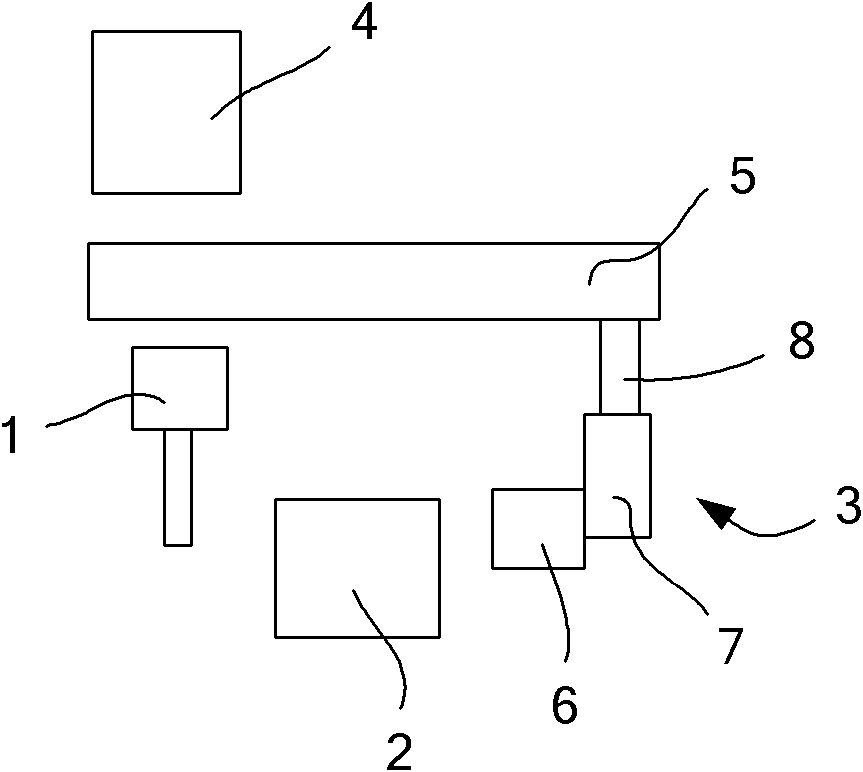

[0020] Such as figure 1 As shown, the present invention includes a sensor 1 , a deviation correction controller 2 and a driving mechanism 3 . Among them, the sensor 1 measures the position of the coil 4 to determine the offset of the coil 4; the deviation correction controller 2 receives the position information sent by the sensor 1, performs calculation and signal processing, and generates a control command; the driving mechanism 3 follows the deviation of the deviation correction controller 2 The sent control command acts to drive the deviation correction frame 5 to move, so as to realize the position deviation correction of the coil 4 .

[0021] The sensor 1 is fixedly arranged for detecting the position of the edge of the coil 4 . And the measured position information is converted into a proportional electrical signal, and then the electrical signal is sent to the deviation correction controller 2 . Since the electrical signal is proportional to the offset of the coil me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com