Multi-air-stream pulse injection-type floatation machine

A technology of airflow pulse and flotation machine, which is applied in flotation, solid separation, etc. It can solve the problems of large difference in specific gravity of different minerals, uneven flotation particle size, similar mineral flotation behavior, etc., and achieve a high degree of automation of the whole machine , high control precision and degree of automation, the effect of small bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

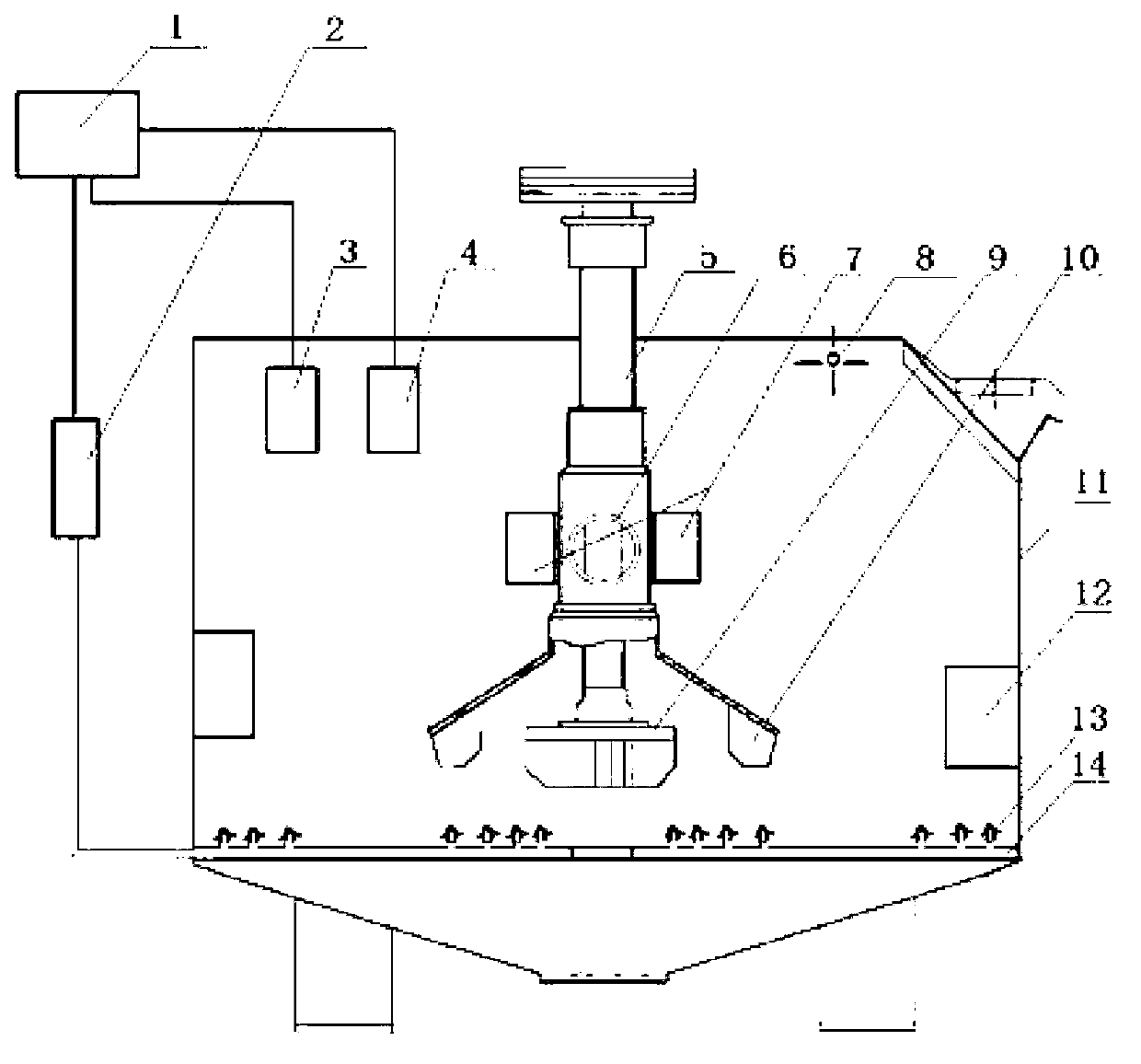

Image

Examples

Embodiment 1

[0018] Embodiment 1: the effect of the present invention's flotation tin-poor polymetallic sulfide ore is as follows:

[0019] 1. During the industrial test of the multi-flow pulse injection flotation machine, the equipment operated well without any failure. The rotor-stator structure design of the flotation machine is reasonable, the impeller speed is properly selected, the slurry particle size distribution in the flotation tank is uniform, there is no stratification of coarse and fine particles, the flotation machine has good suspension capacity of ore particles, the foam layer is stable, and the liquid level does not turn over Stirring force is strong, the slurry flow direction is stable; the ore particles in the tank are evenly distributed, without stratification; there is no dead zone in the tank, and no slurry deposition occurs; it can start normally after parking at full load.

[0020] 2. Mineral accumulation index in flotation: The flotation froth contains an average o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com