Automatic ceramic body forming production line

An automatic forming, ceramic body technology, applied in ceramic forming machines, ceramic forming workshops, auxiliary forming equipment, etc., can solve the problems of reduced production efficiency, unguaranteed continuity and continuity of ceramic production, labor shortage, etc. Achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

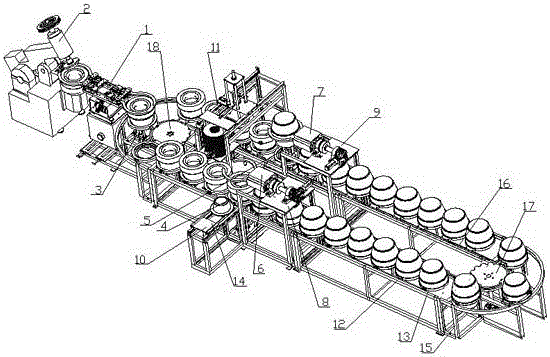

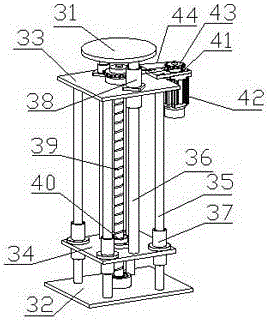

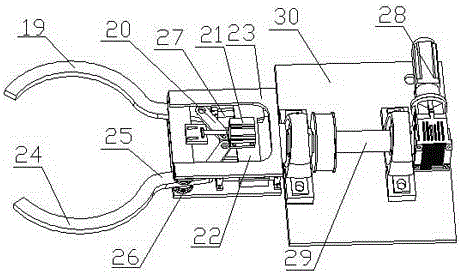

[0035] like figure 1 , 2, 3, and 4, an automatic ceramic body forming production line, including clamping transposition device 1, green body forming machine 2, lifting device I3, lifting device II4, lifting device III5, clamping device I6, clamping device Ⅱ7. Turning device Ⅰ8, turning device Ⅱ9, billet removal device 10, backing plate placement device 11, circulation transmission mechanism 12 and hot air drying pipeline system;

[0036] The circular transmission mechanism 12 is provided with a plurality of brackets 13 for placing molds; the lifting device I3 is arranged at any position in the middle section of the transmission track of the circular transmission mechanism 12, and is located below the brackets 13; The lifting device II4 is arranged at any position of the front section of the transmission track of the circular transmission mechanism 12, and is located below the bracket 13; the lifting device III5 is arranged at any position of the rear section of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com