Winding forming machine for flat type copper wire

A flat copper wire and forming machine technology, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high labor intensity, high manufacturing cost, poor product consistency, etc., to reduce labor intensity of workers, improve The effect of production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

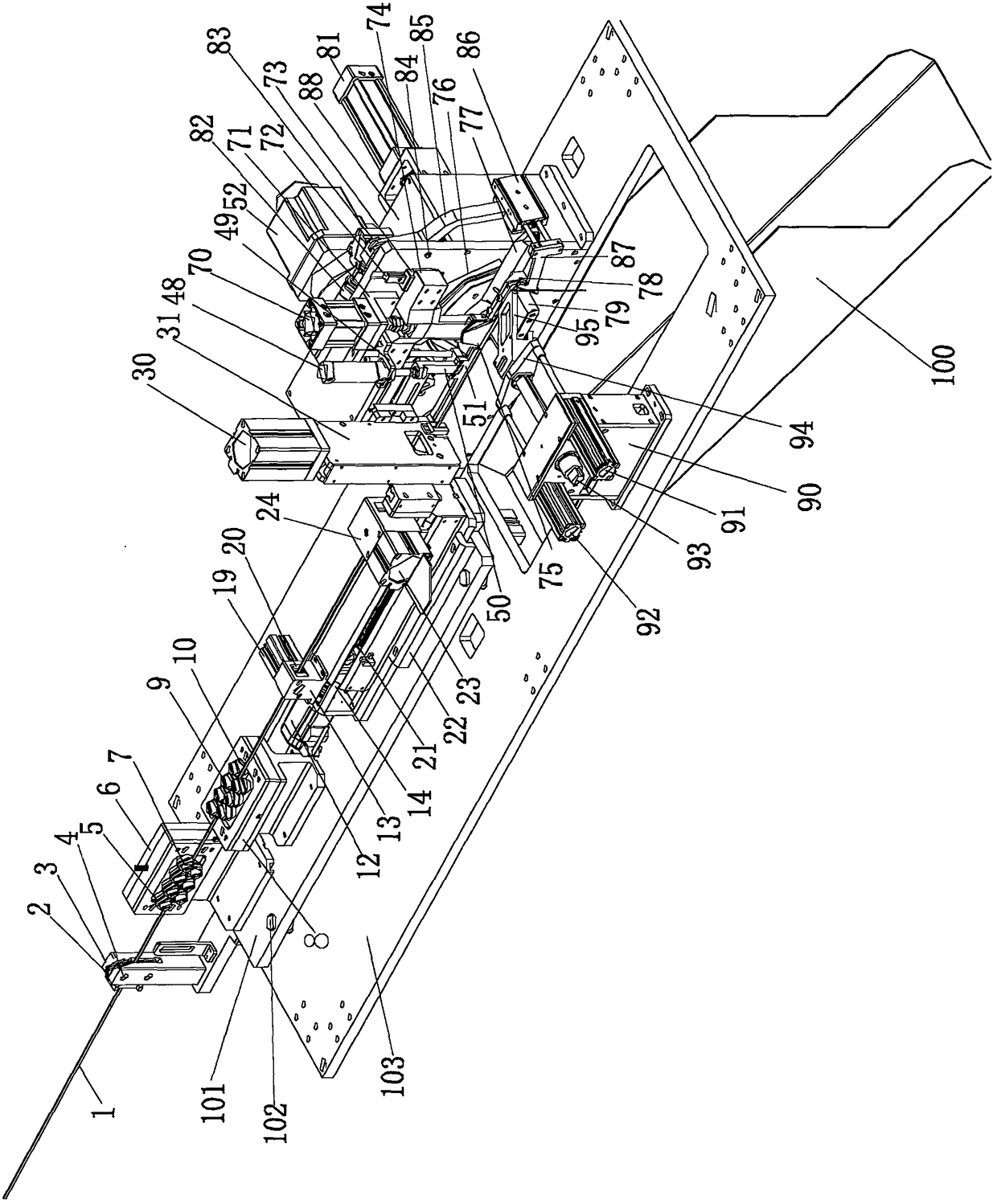

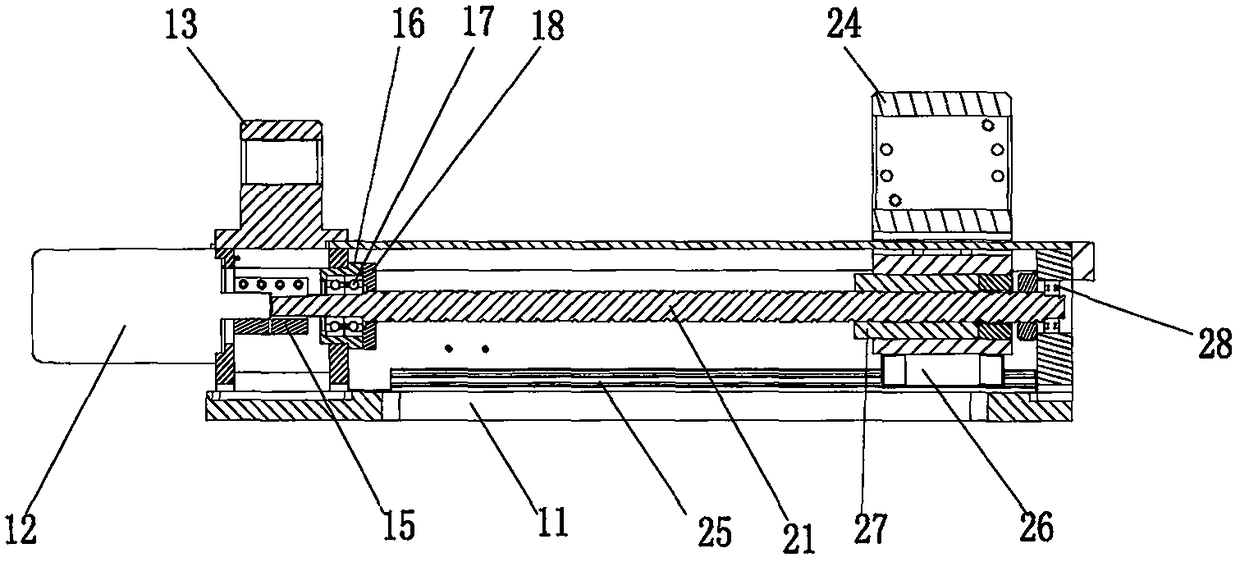

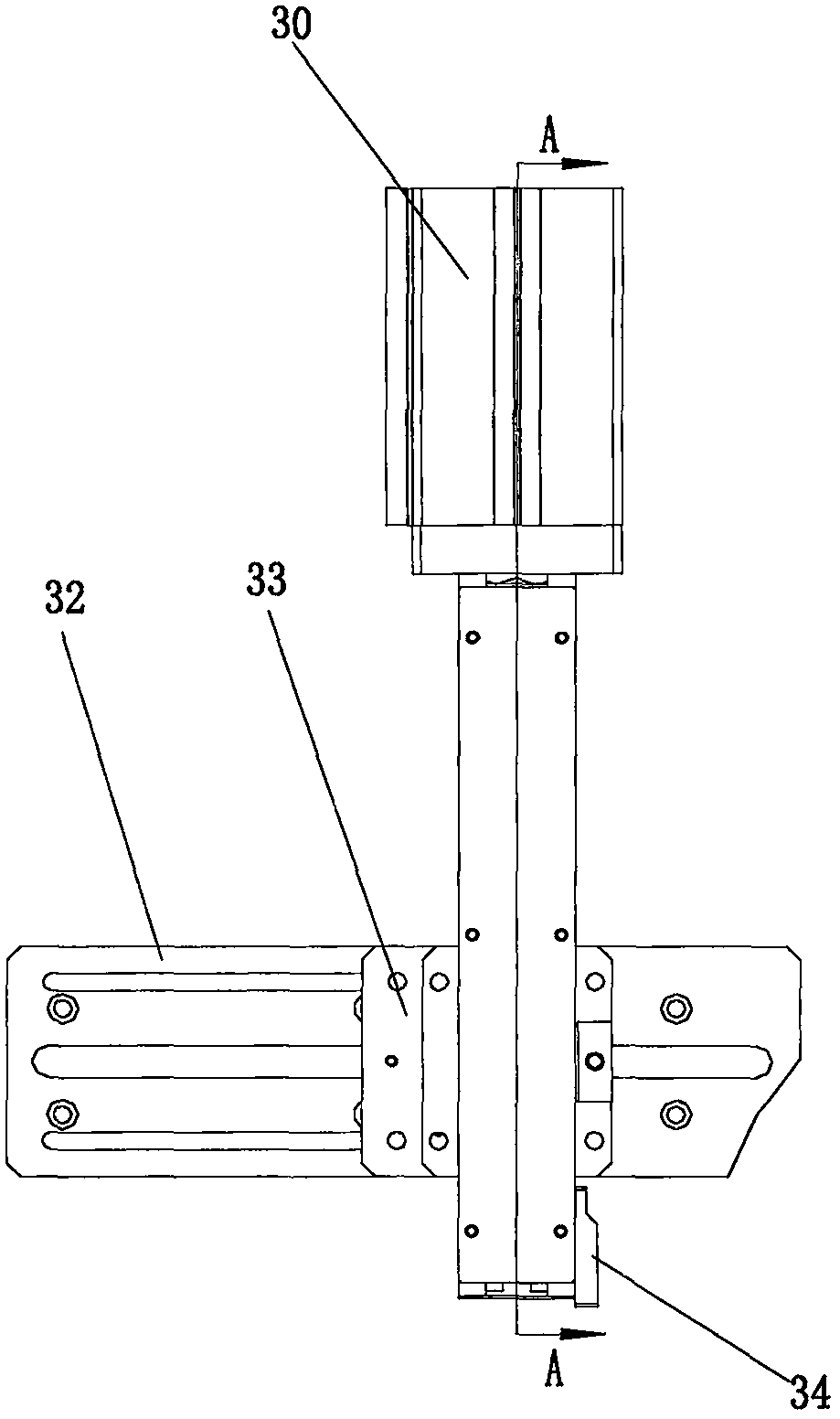

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] refer to Figure 1 to Figure 8 , a flat copper wire winding forming machine, including a platen 103 and a wire fixing seat installed on the platen 103 for fixing the flat copper wire 1, and a vertical alignment device for vertically aligning the flat copper wire 1 Straightening mechanism, horizontal straightening mechanism for horizontal straightening of flat copper wire 1, wire feeding mechanism for flat copper wire 1 conveying, wire trimming mechanism, wire mechanism, wire crimping mechanism, lead wire mechanism, wire folding mechanism, Winding mechanism, wire pushing mechanism and material channel 100 for pushing out the formed coil, the wire fixing seat, vertical straightening mechanism, horizontal straightening mechanism, wire feeding mechanism, wire trimming mechanism, wire mechanism, wire pressing mechanism Mechanism, winding mechanism and line folding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com