Frosted glass reaction tank

A technology of frosted glass and reaction pool, applied in the field of frosted glass processing, can solve the problems of low production efficiency and hand-held injury, and achieve the effects of avoiding injury, reducing investment, and improving production efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

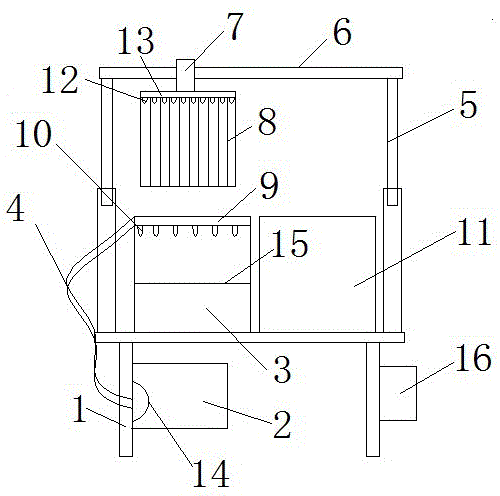

[0015] Such as figure 1 A kind of frosted glass reaction pool shown comprises frame 1, frosting liquid box 2, reaction pool 3 and flexible pipe 4; Described frosting liquid box 2 and reaction pool 3 are installed on the frame 1 respectively; A telescopic support rod 5 is installed on the frame 1; a cross bar 6 is installed on the telescopic support rod 5; a moving block 7 is movably arranged on the cross bar 6; a glass placement frame 8 is connected to the moving block 7; Said liquid spray pipeline 9 is installed in said reaction tank 3; said spray liquid pipeline 9 is provided with high-pressure nozzle 10; said spray liquid pipeline 9 is connected with frosting liquid tank 2 through flexible pipe 4; A cleaning pool 11 is provided on the right side.

[0016] Wherein, the top of the glass placement frame 8 is respectively provided with a glass clip 12 and a dryer 13; an air compressor 14 is provided in the frosting liquid tank 2; a rubber roller 15 is provided in the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com