Honeycomb paper core high speed paper feeding and trimming device

A honeycomb paper core and paper feeding technology, which is applied in metal processing and other directions, can solve the problems of reducing the cutting flatness, limiting the cutting speed of the moving knife, and slow paper feeding speed, so as to improve the cutting flatness and improve the paper cutting speed. The effect of speed and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

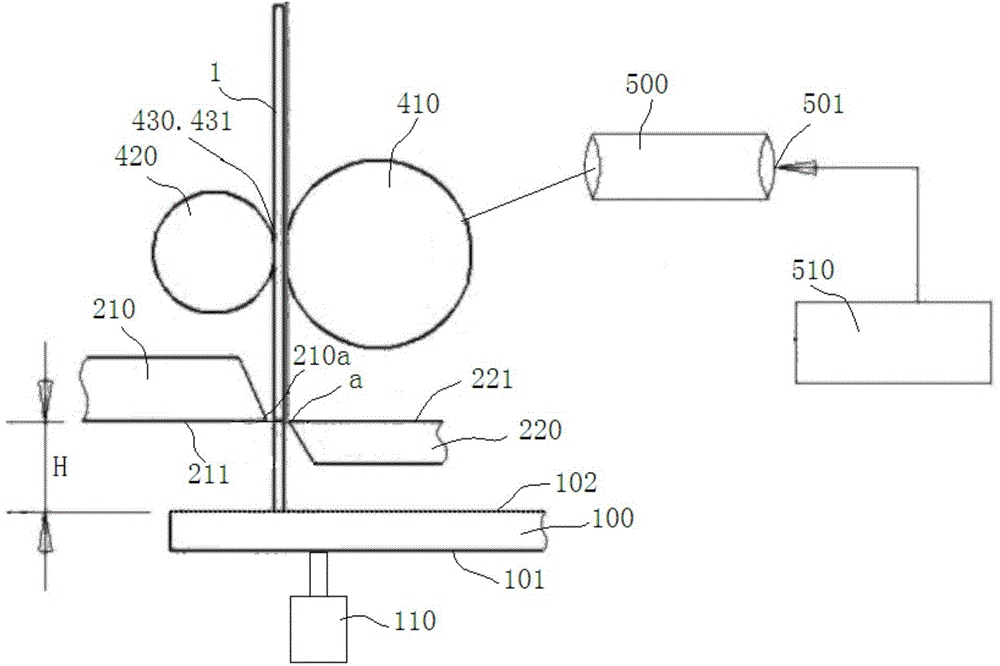

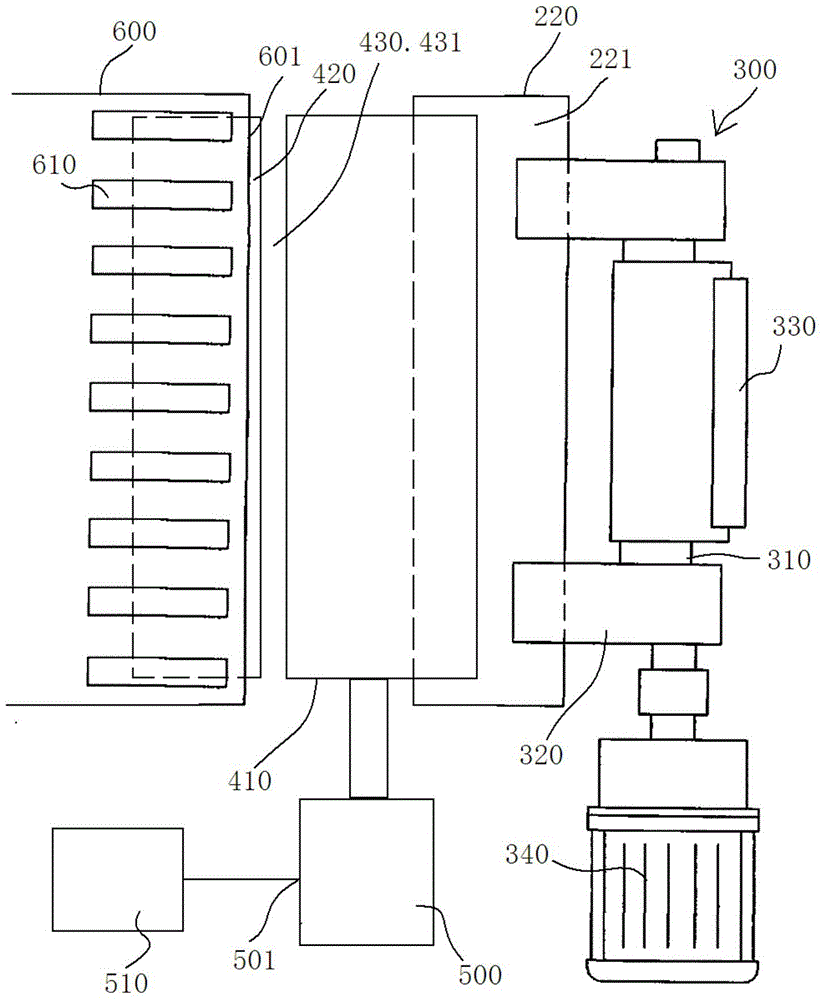

[0030] see Figure 1 to Figure 3 Shown is a honeycomb paper core high-speed paper feeding and cutting device, the bottom 101 of the workbench 100 is connected to the hydraulic lifting mechanism 110, and the height of the workbench 100 can be changed through the hydraulic lifting mechanism 110 to adjust the length of the cut paper. Of course, the hydraulic lifting mechanism 110 can also be replaced with other lifting mechanisms that are easily conceived by those skilled in the art, such as a screw lifting mechanism.

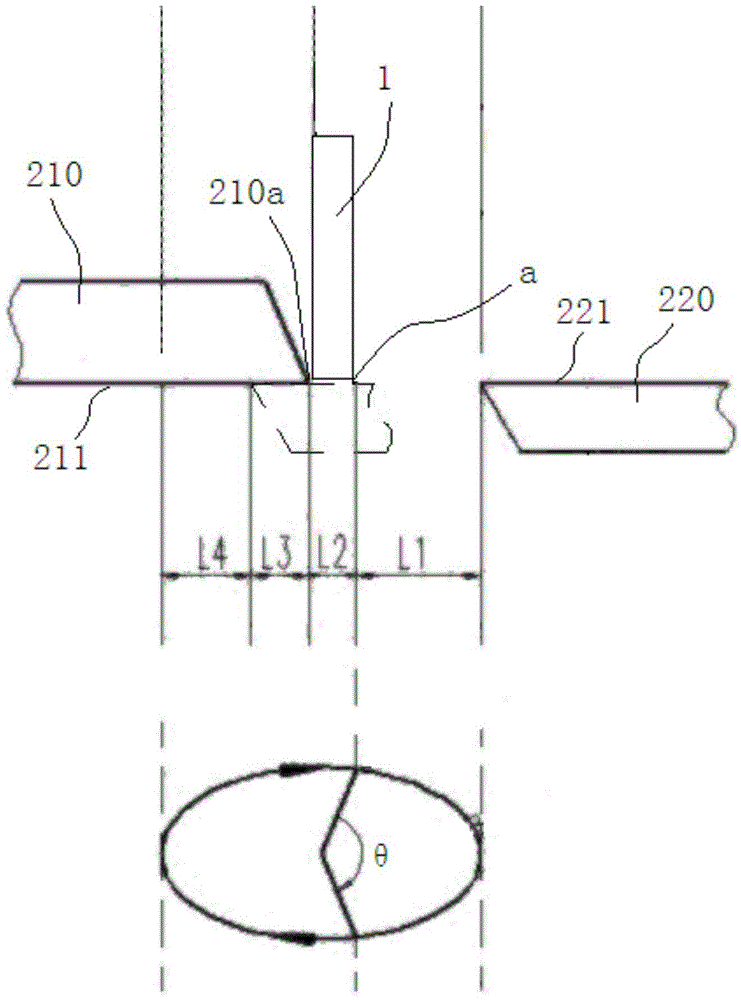

[0031] The fixed knife 210 and the movable knife 220 are arranged above the workbench 100 , and the fixed knife 210 and the movable knife 220 are vertically tangent, that is, the bottom surface 211 of the fixed knife 210 is flush wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com