Silica gel film capable of being bonded with other plastic materials and preparation method thereof

A technology of plastic materials and silicone membranes, applied in the field of silicone membranes, can solve problems such as the difficulty of silicone membranes, achieve the effects of safe and convenient use, scientific and reasonable structure, and avoid peeling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

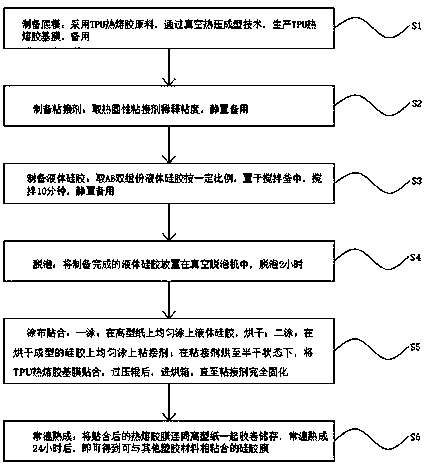

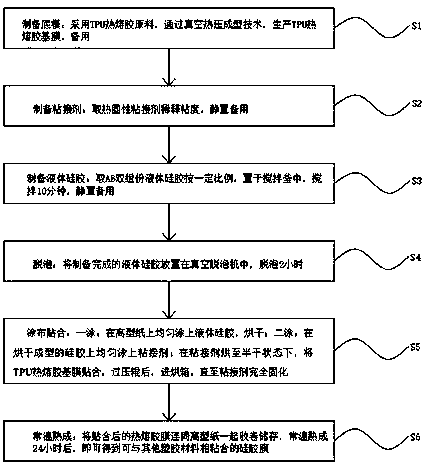

[0040] Example 1: Such as Figure 1-2 As shown, the present invention provides a technical solution, a method for preparing a silica gel film capable of bonding other plastic materials, including the following steps:

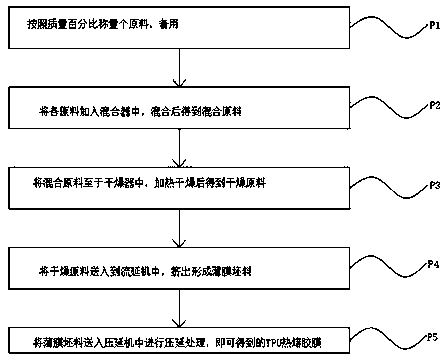

[0041] S1. Preparation of the bottom mold: using TPU hot melt adhesive raw materials, through vacuum hot pressing technology, produce TPU hot melt adhesive base film, standby;

[0042] S2. Preparation of adhesive: take the thermosetting adhesive to dilute the viscosity and let it stand for use;

[0043] S3. Preparation of liquid silica gel: take AB two-component liquid silica gel according to a certain ratio, place it in a stirring tank, stir for 10 minutes, and stand for use;

[0044] S4. Deaeration: place the prepared liquid silica gel in a vacuum deaeration machine for 2 hours;

[0045] S5. Coating and bonding:

[0046] First coating: Coat liquid silica gel evenly on the release paper and dry;

[0047] Second coating: evenly coat the adhesive on the dried silica gel;

[0...

Embodiment 2

[0070] Example 2: Such as Figure 1-2 As shown, the present invention provides a technical solution, a method for preparing a silica gel film capable of bonding other plastic materials, including the following steps:

[0071] S1. Preparation of the bottom mold: using TPU hot melt adhesive raw materials, through vacuum hot pressing technology, produce TPU hot melt adhesive base film, standby;

[0072] S2. Preparation of adhesive: take the thermosetting adhesive to dilute the viscosity and let it stand for use;

[0073] S3. Preparation of liquid silica gel: Take AB two-component liquid silica gel according to a certain ratio, place it in a stirring tank, stir for 10 minutes, and stand for use;

[0074] S4. Deaeration: place the prepared liquid silica gel in a vacuum deaeration machine for 2 hours;

[0075] S5. Coating and bonding:

[0076] First coating: Coat liquid silica gel evenly on the release paper and dry;

[0077] Second coating: apply adhesive evenly on the dried silica gel;

[0078...

Embodiment 3

[0100] Example 3: Such as Figure 1-2 As shown, the present invention provides a technical solution, a method for preparing a silicone film capable of bonding other plastic materials, including the following steps:

[0101] S1. Preparation of the bottom mold: using TPU hot melt adhesive raw materials, through vacuum hot pressing technology, produce TPU hot melt adhesive base film, standby;

[0102] S2. Preparation of adhesive: take the thermosetting adhesive to dilute the viscosity and let it stand for use;

[0103] S3. Preparation of liquid silica gel: Take AB two-component liquid silica gel according to a certain ratio, place it in a stirring tank, stir for 10 minutes, and stand for use;

[0104] S4. Deaeration: place the prepared liquid silica gel in a vacuum deaeration machine for 2 hours;

[0105] S5. Coating and bonding:

[0106] First coating: Coat liquid silica gel evenly on the release paper and dry;

[0107] Second coating: apply adhesive evenly on the dried silica gel;

[0108] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com