Silica gel and PET bonding process

A technology, silica gel technology, applied in the bonding process of silica gel and PET, can solve the problems of poor quality of laminating film, increased material cost, high defective rate, etc., achieve high bonding firmness, reduce labor costs, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

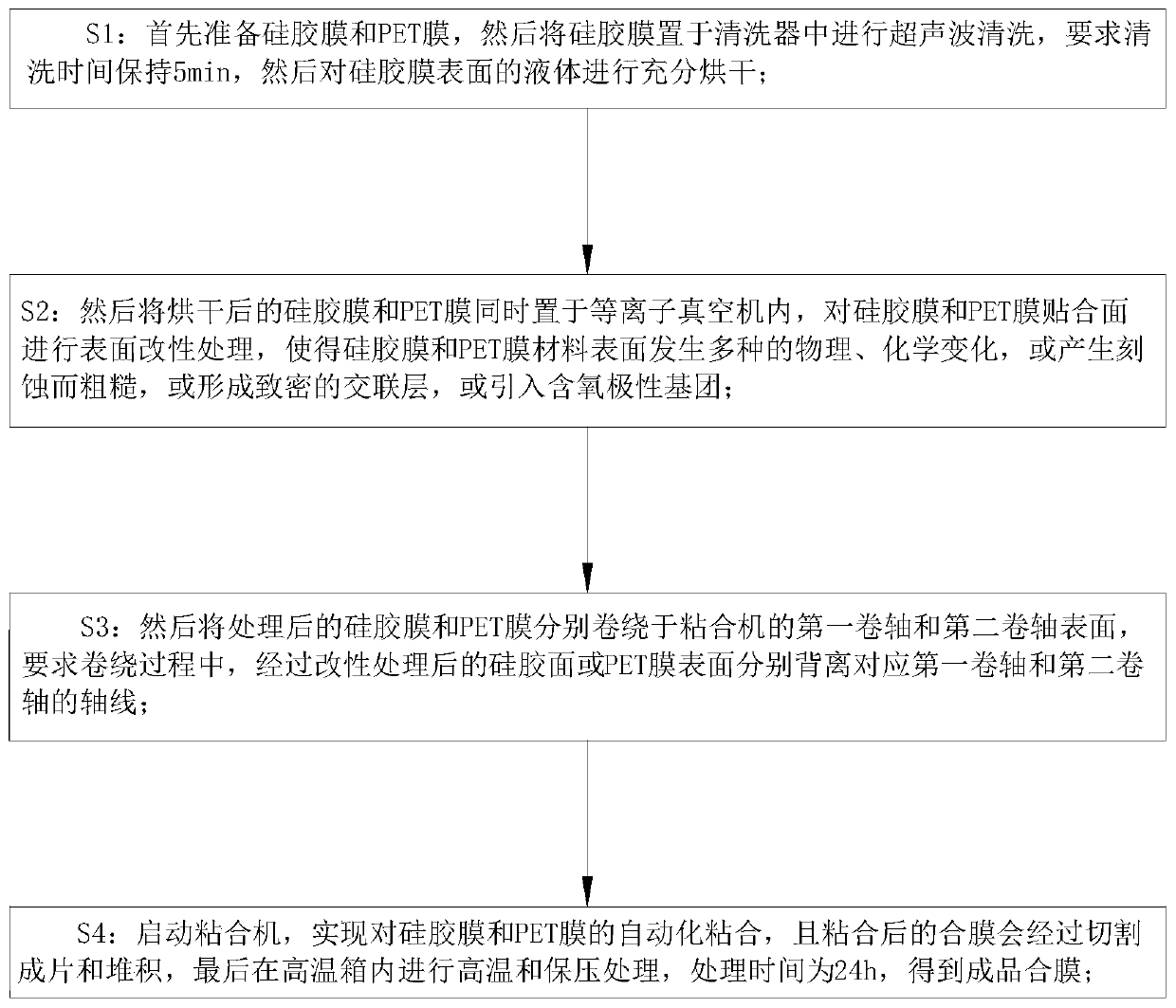

Method used

Image

Examples

Embodiment approach

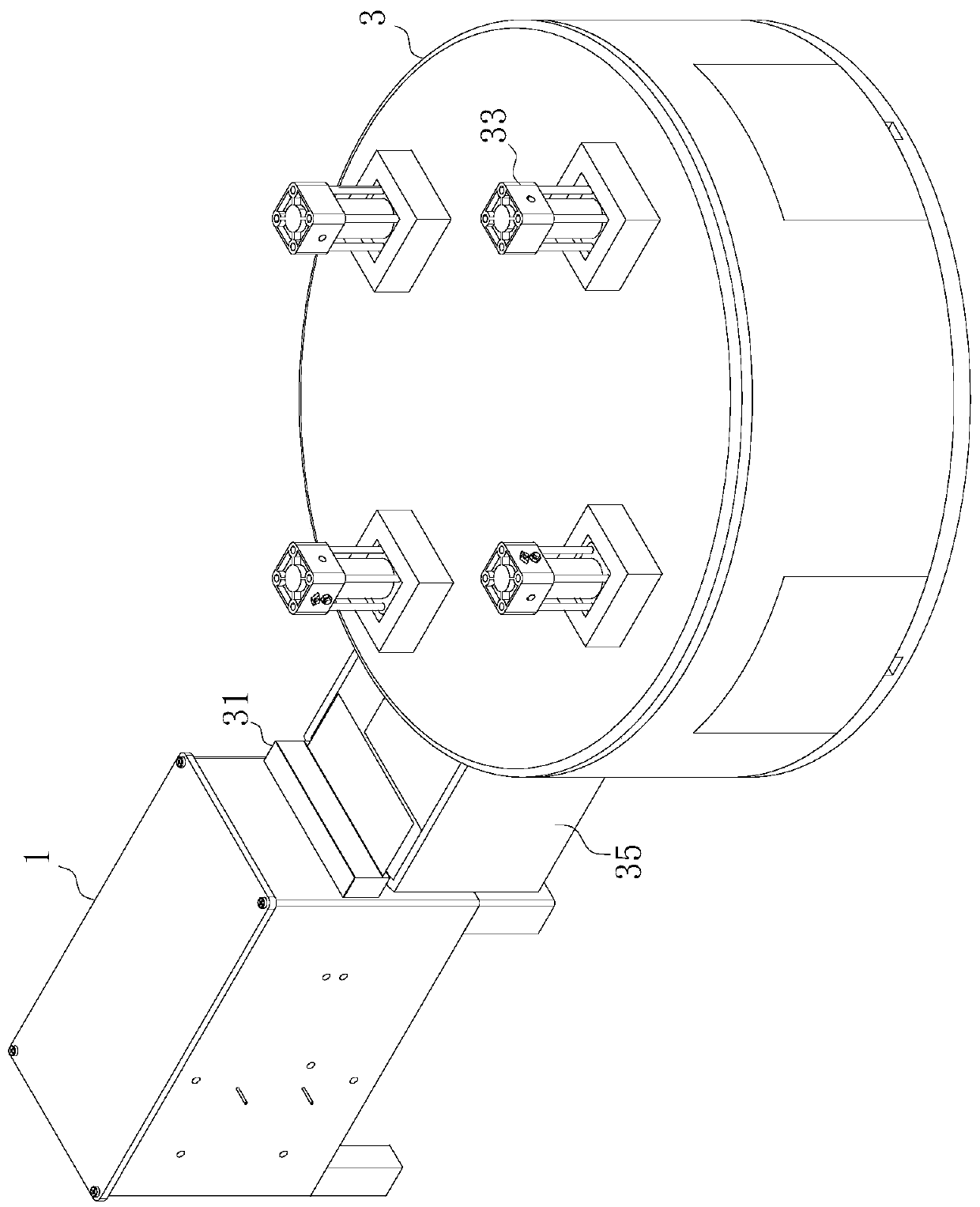

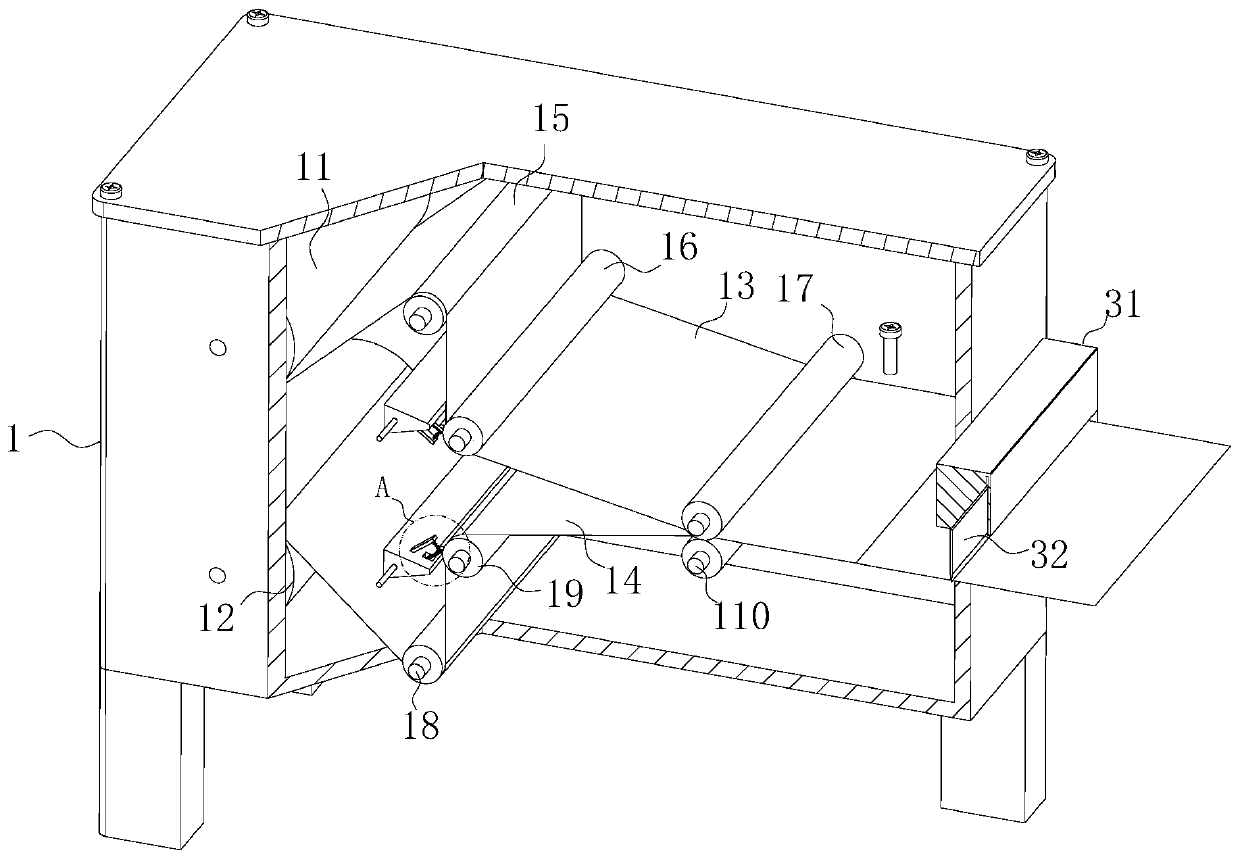

[0037] As an embodiment of the present invention, the right side of the bonding box 1 is provided with a cutting block 31 above the guide hole; the inside of the cutting block 31 is slidingly connected with a cutting knife 32 up and down; the high temperature box The inside of 3 is provided with a pressure box 35; the upper surface of the high temperature box 3 is fixedly connected with a cylinder 33, and the output shaft of the cylinder 33 passes through the upper wall of the high temperature box 3 and extends to the inside of the high temperature box 3; the cylinder 33 The lower end surface of the output shaft of the output shaft is fixedly connected with a pressure plate 34; when working, by setting the cutting block 31 and the cutter 32, the composite film can be quickly cut off, and the consistency of the cut length of the composite film can be guaranteed, and then the composite film after cutting It will fall into the pressure box 35 and accumulate continuously. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com