Wood veneer splicing mechanism

A technology of veneer and cylinder, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of not being able to keep up, not being suitable for widespread promotion, and low operating efficiency, so as to increase production capacity and improve production efficiency , Splicing is simple and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

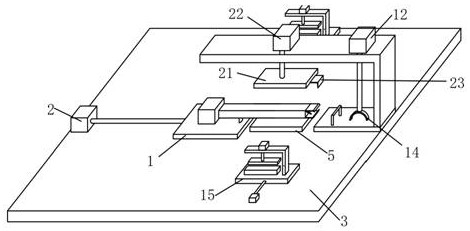

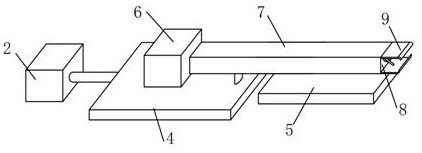

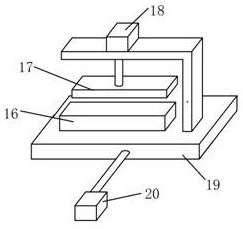

[0027] Combine below Figure 1 to Figure 5 Specific description embodiment:

[0028] Such as figure 2 As shown, the tape pulling mechanism 1 includes a first cylinder 2, the first cylinder 2 is arranged on the left side of the support 3, the output end of the first cylinder is connected with a slide plate 4, and the slide plate slides to the left end of the splicing workbench 5. A second cylinder 6 and a transition piece 7 are fixedly arranged on the slide plate. The transition piece is hollow and both ends are through, the output end of the second cylinder is set in the transition piece, and the end of the output end of the second cylinder is flush with the outlet end 8 of the transition piece (the right end of the transition piece) .

[0029] The outlet end of the transition piece extends to the outside of the slide plate, and two corresponding clips 9 are hingedly arranged at the outlet end of the transition piece. The output end of the second cylinder is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com