Anti-siphoning-pressure one-way valve

A one-way valve, anti-siphon technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

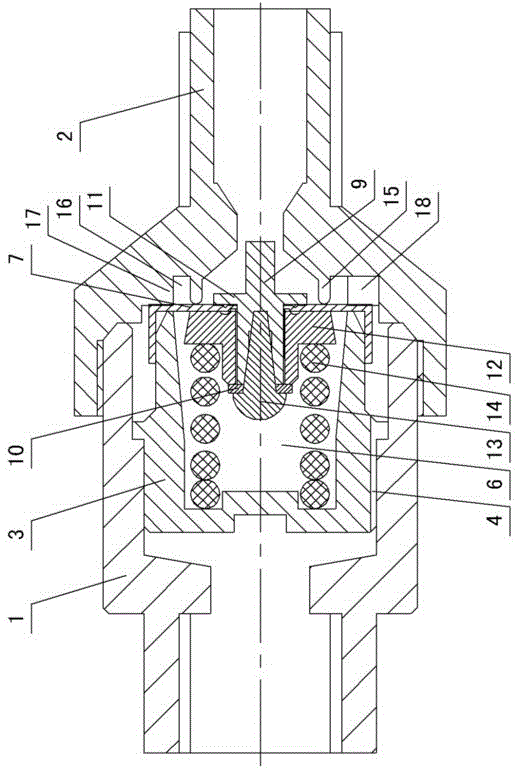

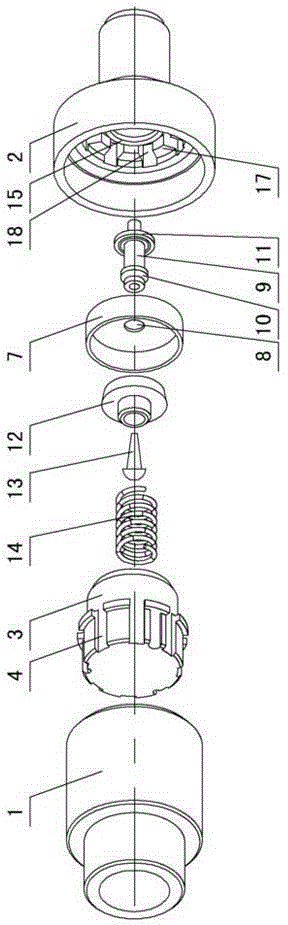

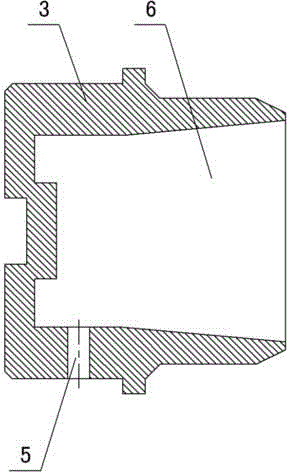

[0009] The invention relates to an anti-siphon pressurized one-way valve, such as figure 1 — image 3 As shown, it is characterized in that it includes a nozzle connector 1 and a nozzle rod connector 2, the nozzle connector is threadedly connected with the nozzle rod connector, one end of the nozzle connector is connected to the nozzle, and the other end is installed with a water outlet seat 3, and the water outlet seat is made of There is a water outlet tank 4 and an air vent 5. There is a cavity 6 in the water outlet seat. The air vent communicates with the cavity. An opening is formed at one end of the cavity of the water outlet seat. A silicone diaphragm 7 is placed on the opening. There is a perforation 8, and a diaphragm fixing seat 9 is arranged in the perforation. There are a spring seat baffle 10 and a diaphragm baffle 11 on the diaphragm fixing seat. One side of the cavity 6 is provided with a spring seat 12, the spring seat baffle plate 10 is in contact with the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com