Single-sided graphene heat dissipation film and preparation method thereof

A technology of ene heat dissipation film and graphene, which is applied in the field of single-sided graphene heat dissipation film and its preparation, can solve the problems of lack of composite supporting equipment, high loss rate, and difficult production process of natural graphite film, so as to solve market application problems and facilitate The effect of stable operation and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

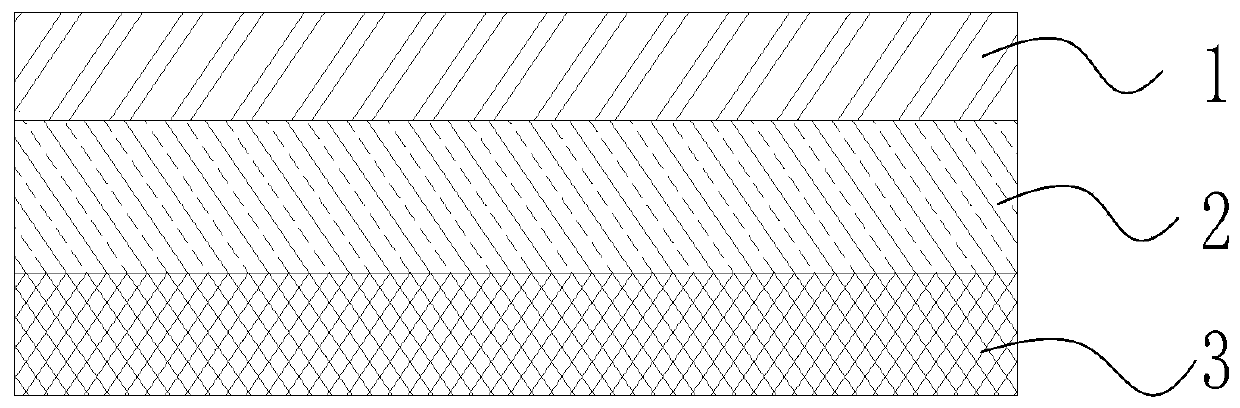

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] Such as figure 1 The schematic diagram of the specific embodiment of a kind of single-sided graphene heat dissipation film of the present invention shown, middle layer is natural graphite layer 2, and the back side of natural graphite layer 2 is bonded on the PET double-sided silica gel film 3, and the front side is coated with oxidation Graphene is then reduced to graphene to form a graphene layer 1 .

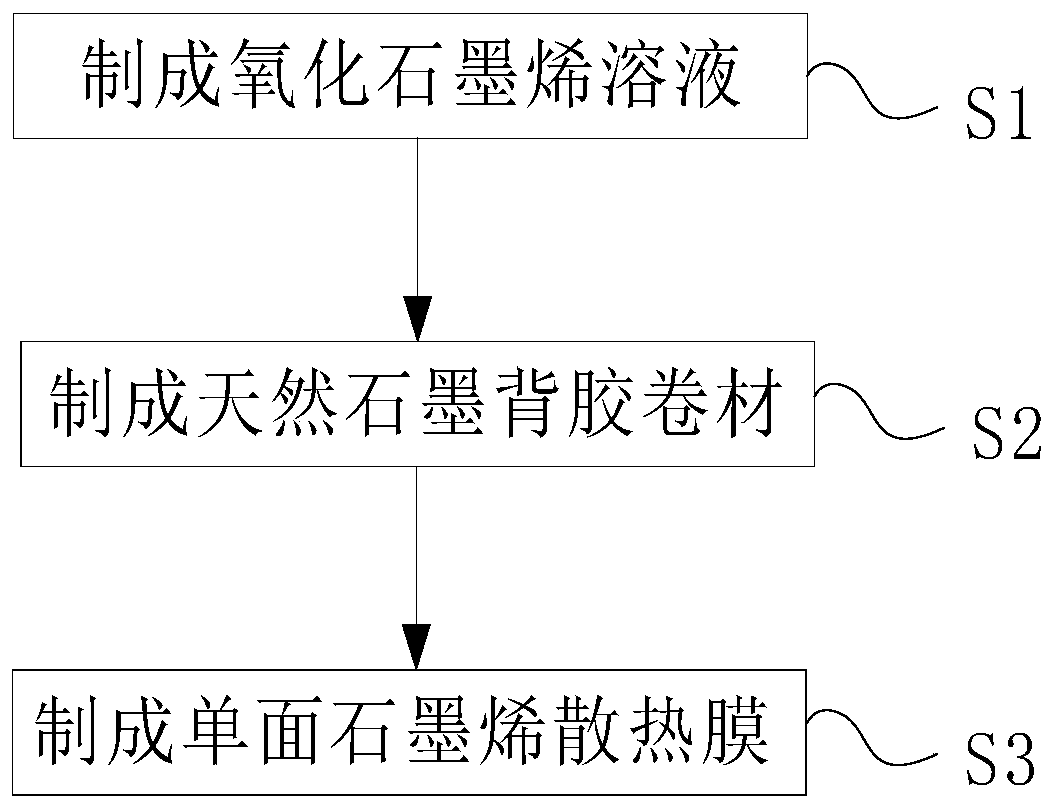

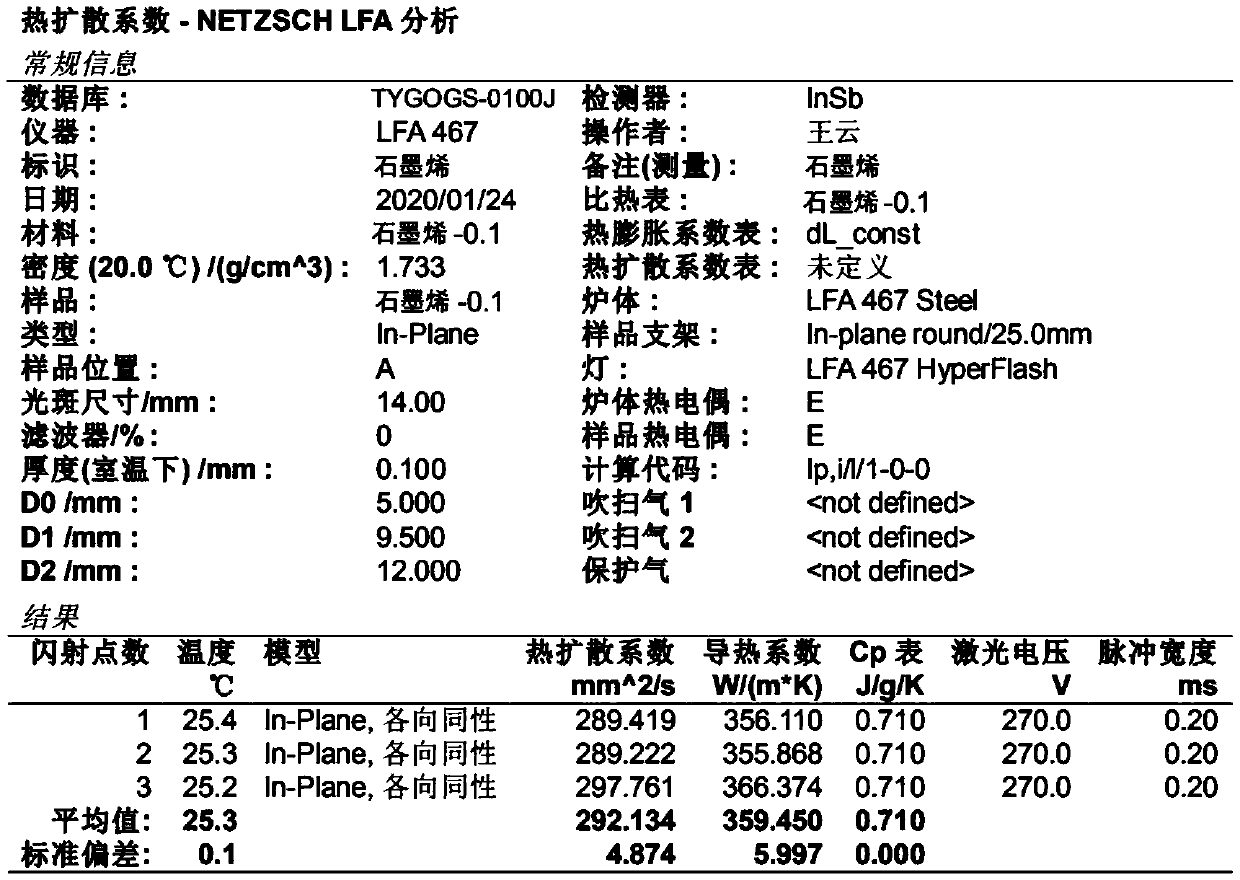

[0026] Such as figure 2 The flow chart of a method for manufacturing a single-sided graphene heat dissipation film is shown, taking the manufacture of TYGOGS-0100J model products as an example, including the following steps:

[0027] S1: Ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com