Patents

Literature

34results about How to "High recovery rate of rare earth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing aluminum from rare-earth feed liquid

ActiveCN101979680AGood aluminum removal effectLow cost of aluminum removalProcess efficiency improvementRare-earth elementKerosene

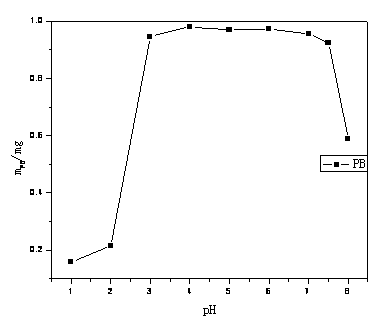

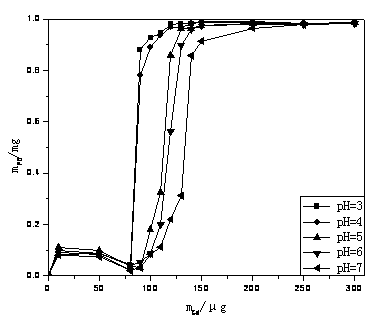

The invention discloses a method for removing aluminum from rare-earth feed liquid, belongs to rare-earth feed liquid treatment technology and aims to provide the method for removing the aluminum from the rare-earth feed liquid, of which the aluminum-removing effect is good, the aluminum-removing cost is low, the rare-earth recovery rate is high, the operation and control are convenient, the process is simple and the investment in equipment is small. The key point of the technical scheme mainly comprises the following steps of: (1) preparing an organic phase from 15 to 25 volume percent of naphthenic acid and 15 to 25 volume percent of alcohol-kerosene; (2) adding the prepared organic phase and the rare-earth feed liquid into a stirring tank in a volume ratio of 2-5:1, starting the tank, stirring and uniformly mixing; (3) adding alkaline solution into the mixed liquid obtained in the step (2) with stirring, wherein the total number of moles of the added alkali is 50 to 100 percent of that of rare-earth elements in the rare-earth feed liquid; and (4) after adding the alkaline solution, continuously stirring for a certain time, stopping stirring and standing for a certain time, wherein the solution is separated into an aqueous phase and an organic phase and the aqueous phase is the rare-earth feed liquid from which the aluminum is removed. The method is applied to aluminum removal for the rare-earth feed liquid.

Owner:广东省富远稀土有限公司 +1

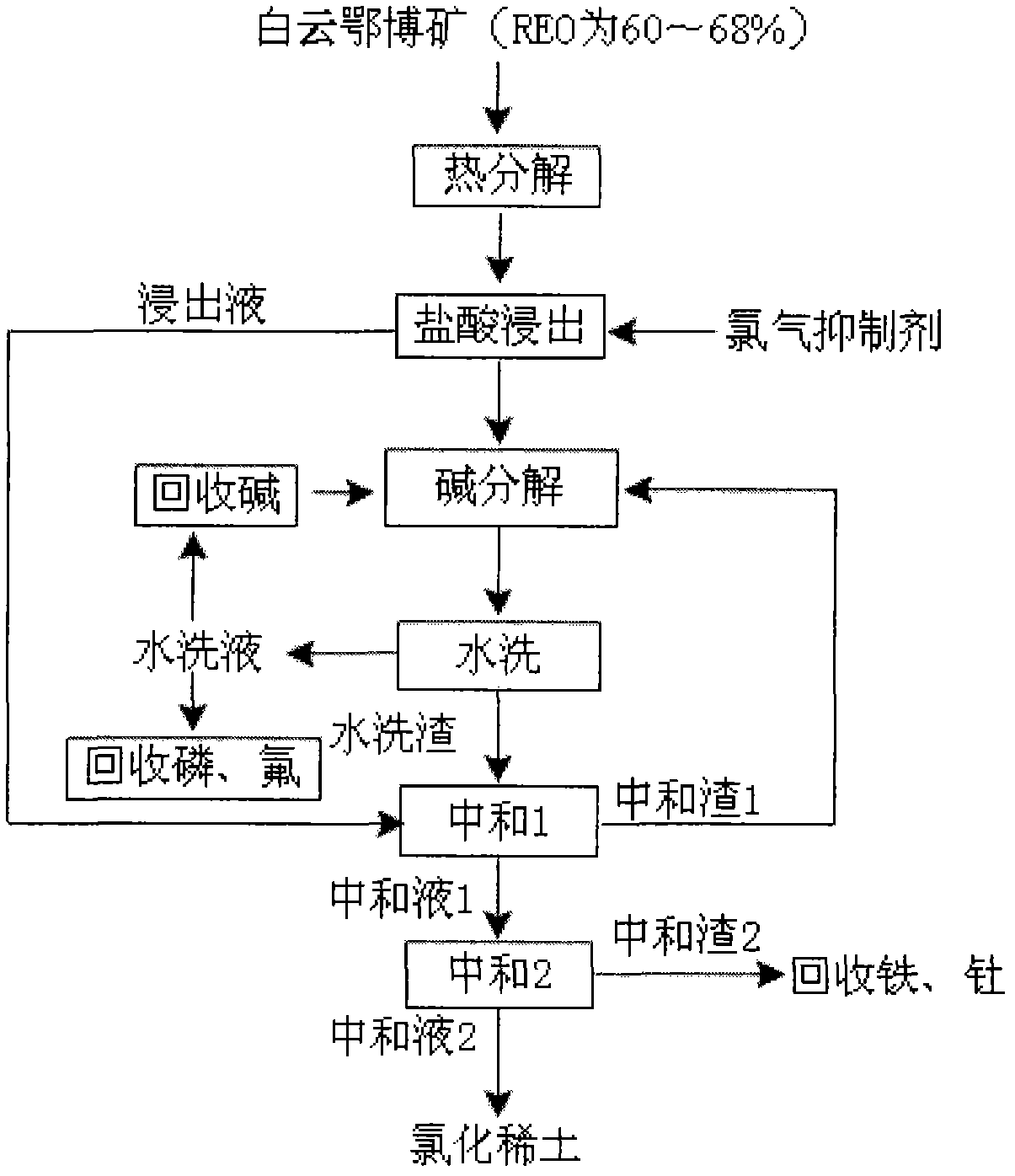

A New Method for Preparing Rare Earth Chloride from Baiyun Obo Rare Earth Concentrate

The invention relates to a new method for preparing rare earth chloride by using Baiyunebo rare earth concentrate and belongs to the field of wet-process metallurgy. The invention comprises the following steps: performing thermal decomposition, wherein a raw material used is Baiyunebo mixed rare earth concentrate with a grade of 60 to 80 percent; leaching in hydrochloric acid, namely leaching oreobtained after thermal decomposition in hydrochloric acid; performing alkaline decomposition, namely decomposing filter residue obtained after leaching in hydrochloric acid with solution of sodium hydroxide; washing, namely washing the ores obtained after alkaline decomposition with water till the pH value is 7 to 9, and recovering fluorine and phosphorus from washing solution; performing primaryneutralization, namely mixing hydrochloric acid leachate and water washing residue, and neutralizing till the pH value is 0.5 to 2.5; and performing secondary neutralization, namely neutralizing the filtrate obtained by the primary neutralization till the pH value is 4 to 5, wherein the filtrate of the secondary neutralization is solution of rare earth chloride. The method has the advantages of facilitating recovery of other elements, avoiding waste gas, waste water and waste residue, along with small alkali consumption, stable process and high rare earth recovery rate of more than or equal to 95 percent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

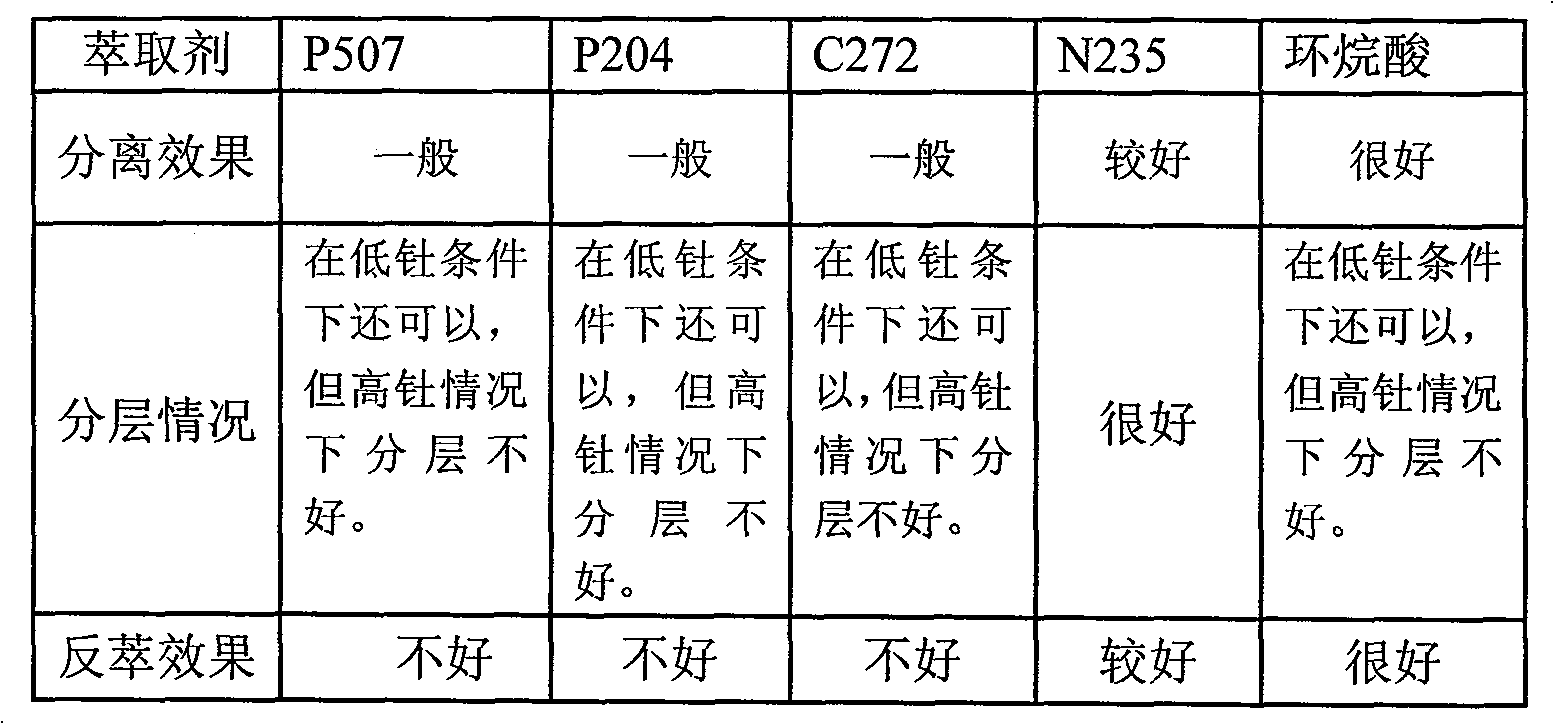

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN1804063AImprove stripping efficiencyReduce acid consumptionProcess efficiency improvementRare-earth elementMaterial consumption

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Recovery method of rare earth elements in NdFeB (neodymium iron boron) waste materials

InactiveCN104087755AHigh recovery rateImprove solubilityProcess efficiency improvementRare-earth elementRecovery method

The invention discloses a recovery method of rare earth elements in NdFeB (neodymium iron boron) waste materials, belonging to the technical field of recovering of rare earth resource. The recovery method comprises the following steps: (1) evenly mixing aluminum fluoride powder and cryolite powder according to the mass ratio of 1:1-1:10, to obtain a cryolite-aluminum fluoride mixture; (2) crushing the NdFeB waste materials into granules with granule size of 4-6mm and burying into the cryolite-aluminum fluoride mixture; (3); putting cryolite-aluminum fluoride mixture with buried NdFeB waste materials into an electric furnace and reacting for 3-12h at the temperature of 900-1200 DEG C; and (4) conducting solid-liquid separation to the product obtained after reaction to obtain solid residue and fused salt respectively, wherein the solid residue is waste steel, and the fused salt is a rare earth fluoride-cryolite-aluminum fluoride mixture. The unoxidized rare earth elements in the NdFeB waste materials can be selectively extracted through aluminum fluoride, rare earth oxidized into oxides can be better dissolved by cryolite, and therefore the recovery rate of rare earth can be greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for extracting and recovering rare earth elements from waste phosphor

InactiveCN104232947ASimple processEasy to operateProcess efficiency improvementOxalateRare-earth element

A method for extracting and recovering rare earth elements from waste phosphor comprises the following steps: (1) concentrated sulfuric acid is added into the waste phosphor, the mixture is uniformly mixed and placed into a high-temperature furnace for roasting, and rare earth is converted into a sulfate form; (2) a solid product after roasting is leached by water, rare earth sulfate enters the water and filtered, a leaching solution after filtering is separated from leaching residues; (3) oxalic acid is added into the leaching solution, pH is adjusted, rare earth is precipitated in a oxalic acid rare earth form, and rare earth oxide is obtained after filtering, drying and roasting. According to the method, the waste phosphor is subjected to processes of sulfatizing roasting, leaching, oxalic acid precipitation, oxalic acid rare earth roasting and the like to recover the rare earth elements in the waste phosphor, the process is simple, the operation is convenient, the cost is lower and the rare earth recovery rate is high.

Owner:龙南市中利再生资源开发有限公司

Monazite ore comprehensive utilization and recovery process

InactiveCN106367590ARealize comprehensive utilizationReduce pollutionProcess efficiency improvementDecompositionRare earth

The invention relates to a monazite ore comprehensive utilization and recovery process, wherein monazite and xenotime and other associate minerals are completely separated through mineral dressing, and alkali decomposition treatment, preferred dissolving, complete dissolving and extraction separation are used, such that the recovery rate of rare earth, uranium and thorium is improved, and the production of radioactive waste residue is reduced. According to the present invention, the comprehensive utilization of the radioactive waste residue is achieved, the amount of the radioactive waste residue is reduced, and the environmental pollution is avoided; during the mineral dressing process, the titanium-containing ilmenite and the monazite are separated, such that the problem that titanium enters the subsequent rare earth, uranium, thorium extraction process so as to easily cause the generation of the three-phase matter is avoided; and H2O2 is added during the preferred dissolving process of the hydrochloric acid, such that the recovery rate of the rare earth is easily increased, and the extraction separation pressure of the subsequent complete dissolving residue is reduced.

Owner:永州市湘江稀土有限责任公司

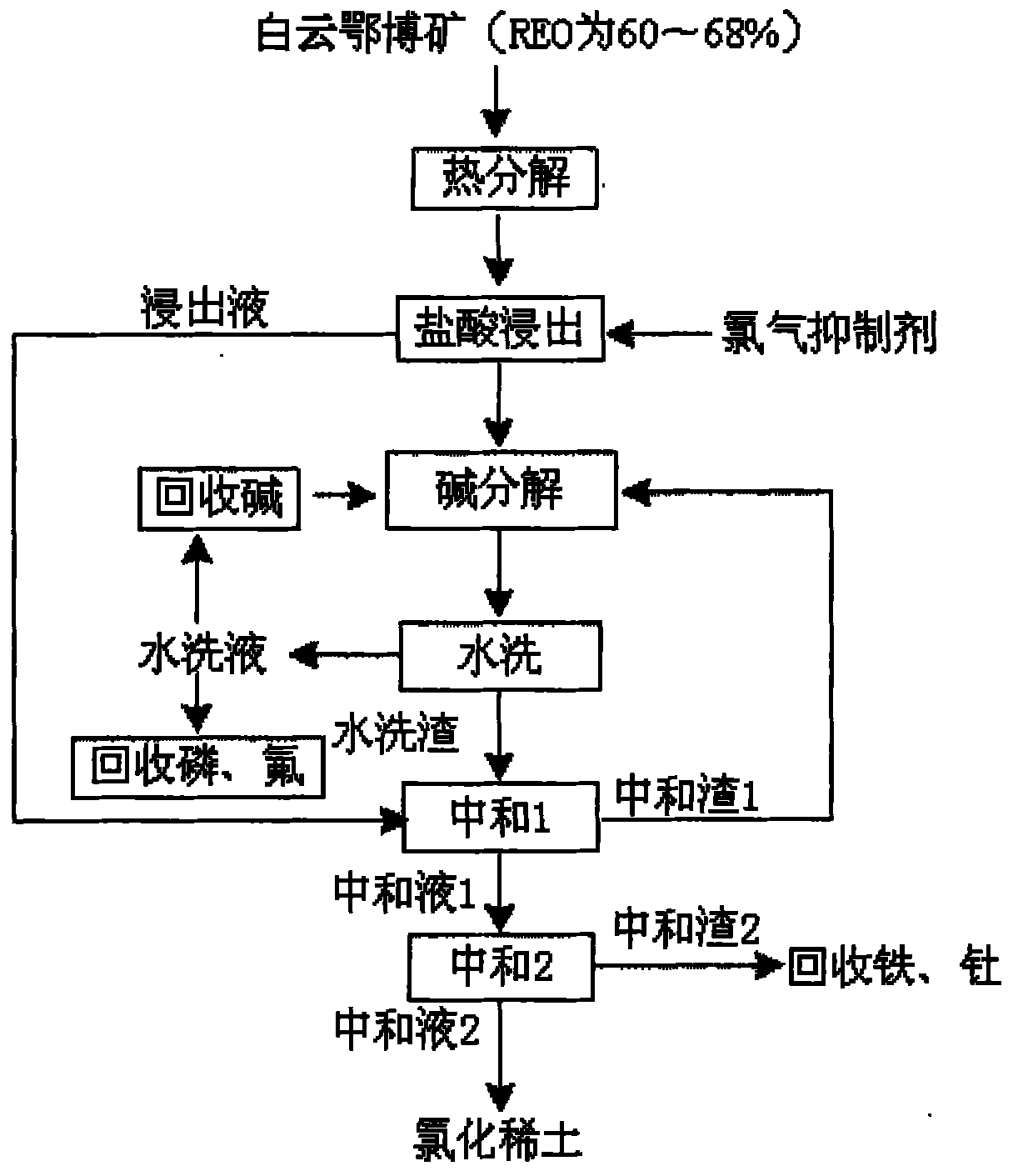

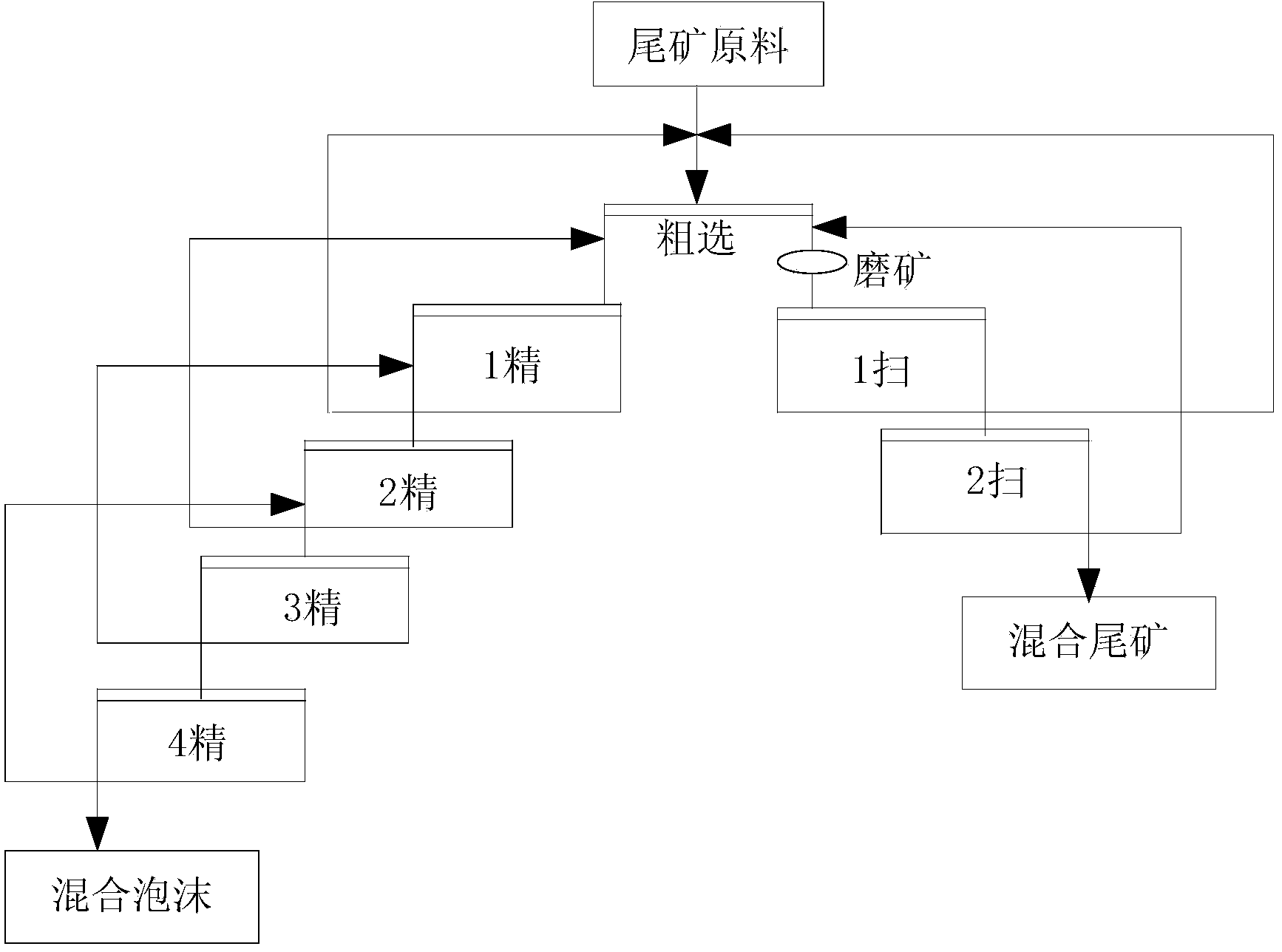

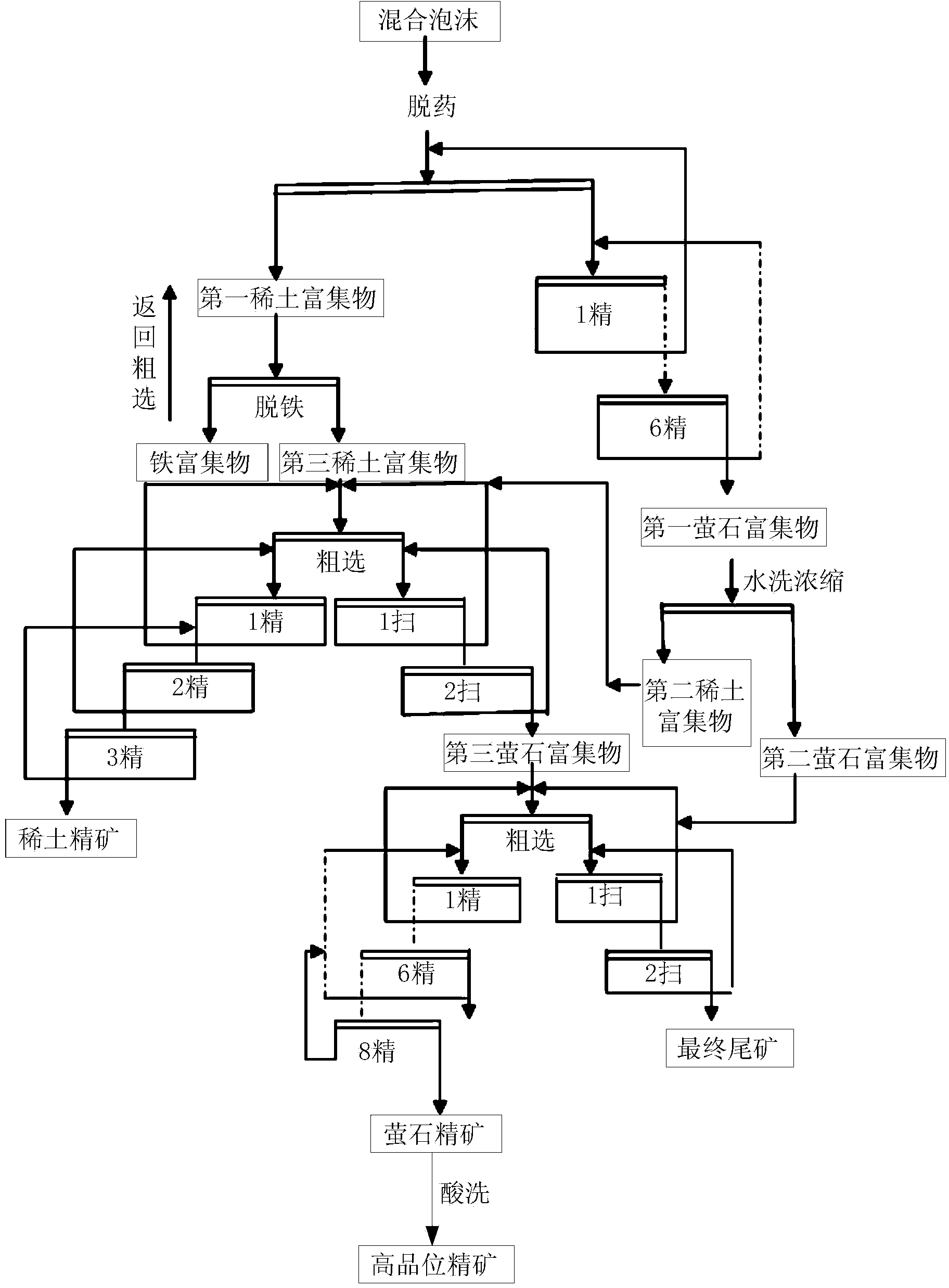

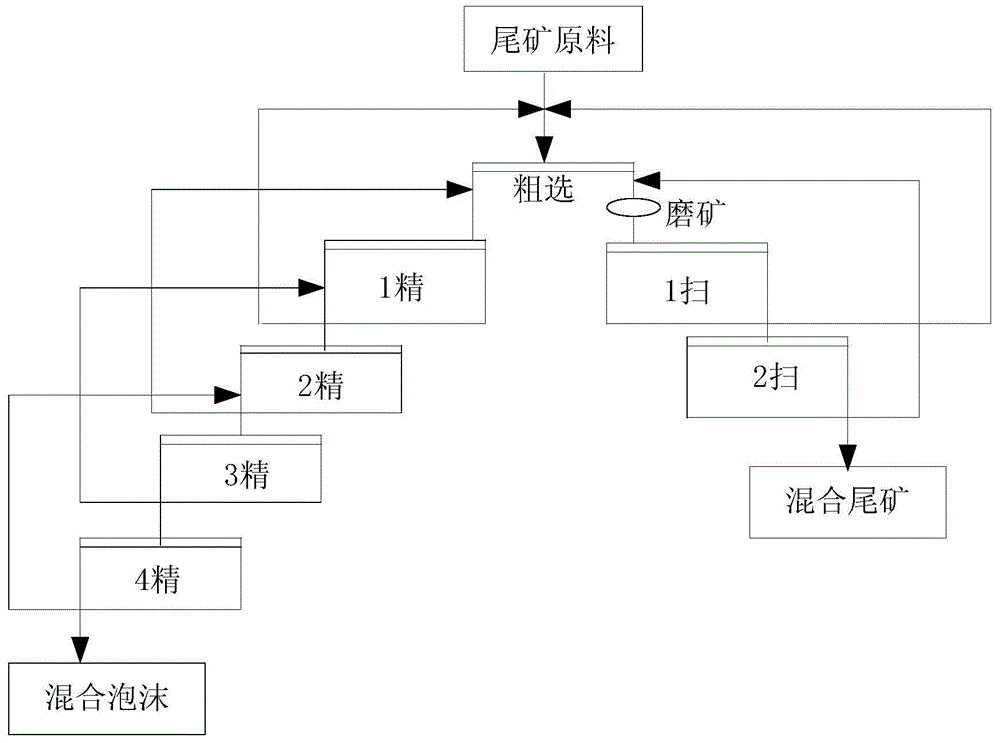

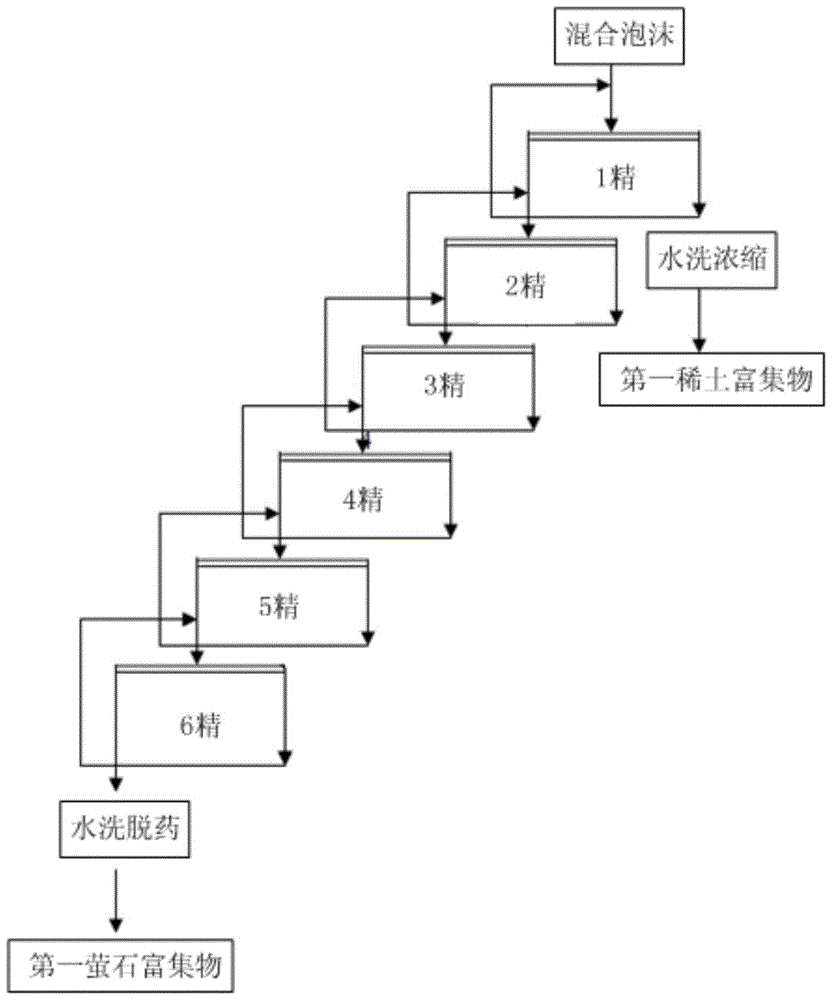

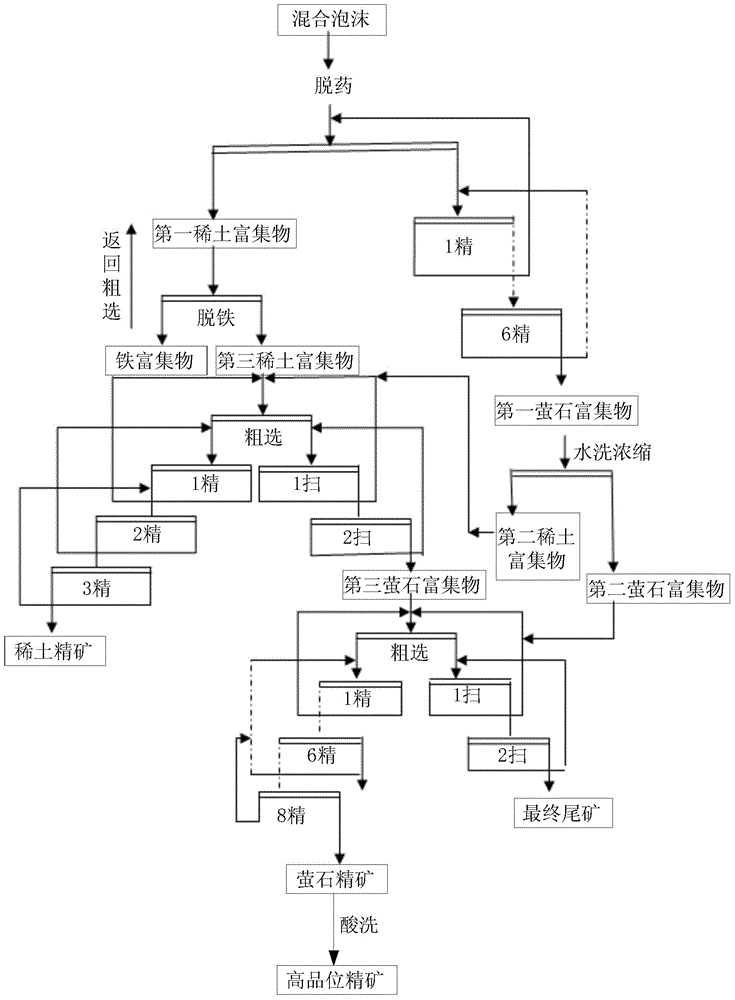

Technique of improving rare earth recovery rate and fluorite grade in tailings

InactiveCN103831173AHigh recovery rate of rare earthRaise the gradeFlotationRare earthMaterials science

The invention discloses a technique of improving rare earth recovery rate and fluorite grade in tailings, and the technique of improving rare earth recovery rate and fluorite grade in tailings comprise the following steps of : (1) mixing foam and mixing tailings are obtained through level one roughing, multistage of scavenging and multistage of refined selection of the tailings raw material; (2) total rare earth enrichment content and total fluorite enrichment content are obtained by separating the mixing foam; (3) rare earth concentrate is obtained through the level one roughing, multistage of scavenging and multistage of refined selection of the total rare earth enrichment content; (4) fluorite concentrate is obtained through the level one roughing, multistage of scavenging and multistage of refined selection of the total fluorite enrichment content. The technique of improving rare earth recovery rate and fluorite grade in tailings is capable of improving rare earth recovery rate and fluorite grade in tailings.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Beneficiation method of high-mud micro-fine particle rare earth minerals

The invention relates to a beneficiation method of high-mud micro-fine particle rare earth minerals. The beneficiation method includes the following steps that magnetic separation is carried out afterreselection to obtain magnetic separation concentrates and magnetic separation tailings; classification of the magnetic separation concentrates is carried out, wherein the magnetic separation concentrates in the +A size fraction are subjected to spiral chute reselection and shaker reselection to obtain shaker rare earth concentrates and shaker tailings, the magnetic separation concentrates in the-A size fraction is subjected to slurry adjusting, and one-time flotation roughing, one-time flotation sweeping and one-time blank selection are carried out to obtain flotation coarse concentrates; and the flotation coarse concentrates are subjected to reselection to obtain centrifugal reselection rare earth concentrates and centrifugal reselection rare earth middlings, and the shaker rare earthconcentrates and the centrifugal reselection rare earth concentrates are combined into total rare earth concentrates. By means of the beneficiation method, the processing capacity per unit area is high, the sorting efficiency is high, and the floor space is saved. The method combining flotation and reselection is adopted, the consumption of flotation reagents is small, the cost is low, the mineralseparation enrichment ratio is high, and the rare earth recovery rate is high.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Method for extracting rare earth from rare earth-containing sludge

ActiveCN104878202AHigh extraction rateImprove extraction efficiencyProcess efficiency improvementRare-earth elementSludge

The invention provides a method for extracting rare earth from rare earth-containing sludge. The method comprises the following steps: 1, allowing the rare earth-containing sludge to contact with an acidic aqueous solution in order to leach the rare earth-containing sludge, and separating to obtain a rare earth element-containing leachate; and 2, allowing the leachate to contact with an organic solvent containing an extraction agent, and extracting to obtain a raffinate water phase and a rare earth element-containing extraction organic phase, wherein the extraction agent is a phosphorus-to-oxygen double bond-containing phosphorus-containing extraction agent, carboxylic acid extraction agent and sulfur-to-oxygen double bond-containing sulfur-containing extraction agent mixture. The method allows rare earth to be leached and extracted from the rare earth-containing sludge in a high yield mode and rare earth chloride to be prepared, the recovered rare earth chloride can be used for producing catalysts, and the method has the advantages of simple whole process, environmental protection, low energy consumption, less production device investment and low operating cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

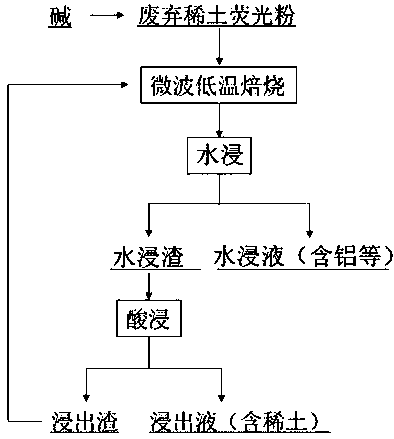

Method for cleanly and efficiently extracting rare earth elements from waste fluorescent powder

InactiveCN111560520AReduce dosageImprove leaching rateProcess efficiency improvementRare-earth elementPregnant leach solution

The invention relates to a method for cleanly and efficiently extracting rare earth elements from waste fluorescent powder, and belongs to the technical field of recycling the waste rare earth fluorescent powder. The waste fluorescent powder and alkali are mixed evenly at the mass ratio of 1:(0.1-10), and a mixture is obtained; the obtained mixture is heated to the temperature of 300-800 DEG C atthe microwave power of 1-5 kW to be subjected to low-temperature calcination for 0.5-1 h, and a calcined material is obtained; the calcined material is ground into powder, then a water solution is added according to the liquid-solid ratio of (1-6):1 ml / g, water leaching is carried out at the temperature of 25-80 DEG C for 5-30 min, after solid-liquid separation, water leaching residues and aluminum-containing aqueous leachate are obtained, and the water leaching residues are repeatedly water-leached 1-5 times; and a hydrochloric acid solution is added into the water leaching residues accordingto the liquid-solid ratio of (5-10):1 ml / g, acid leaching is carried out at the temperature of 25-80 DEG C for 0.5-2 h, and after solid-liquid separation, leaching residues and rare-earth-containingleachate are obtained. The method has the beneficial effects of being low in cost and high in rare earth recovery rate, achieving energy saving and environmental friendliness and the like.

Owner:EAST CHINA UNIV OF TECH +1

Method for recovering rare earth from rare earth-containing wastewater

ActiveCN104878201AHigh recovery rate of rare earthReduce pollutionProcess efficiency improvementMolecular sieveAqueous solution

The invention provides a method for recovering rare earth from rare earth-containing wastewater. The method comprises the following steps: 1, allowing the rare earth-containing wastewater to contact with an alkaline precipitating agent capable of precipitating rare earth metal elements, and carrying out solid-liquid separation after settlement to obtain a first solution and a rare earth precipitate; and 2, allowing the rare earth precipitate to contact with an aqueous solution containing hydrofluoric acid, and carrying out solid-liquid separation after settlement to obtain a second solution and rare earth fluoride. The method allows the rare earth metal elements to be effectively recovered, the recovery rate of the rare earth metal elements to be high and rare earth and fluoride in a raffinate obtained after recovery to reach environmental protection standard requirements, and the final raffinate subjected to an acid-base neutralization reaction is basically neutral and basically has no pollution to environment; and the rare earth fluoride obtained after recovery through the method is purified rare earth, can be used for molecular sieve modification, and can also be used in production of arc carbon rods and special steel alloys as an additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

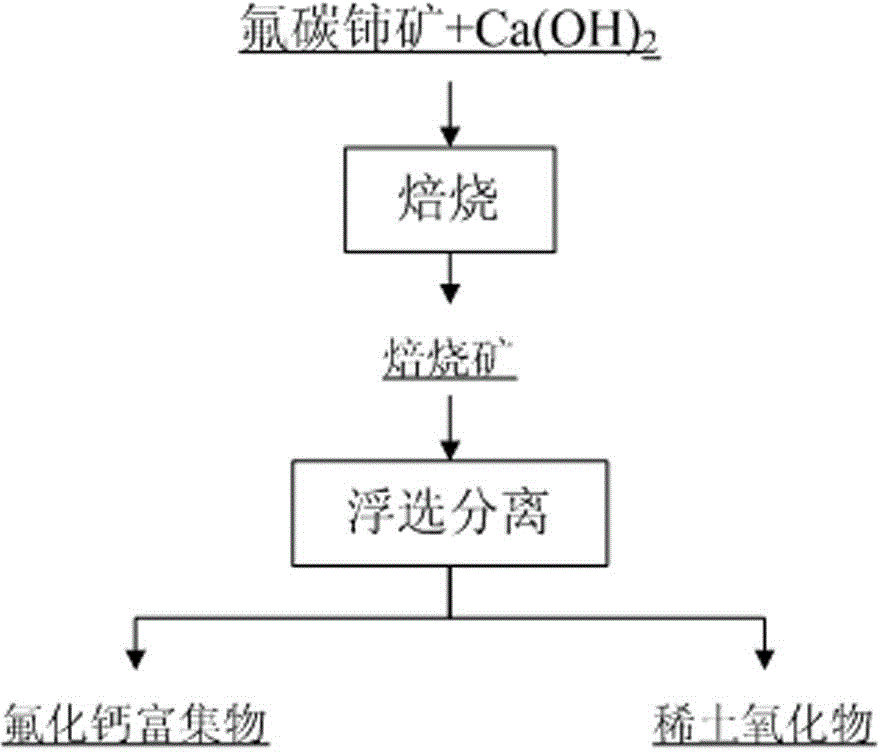

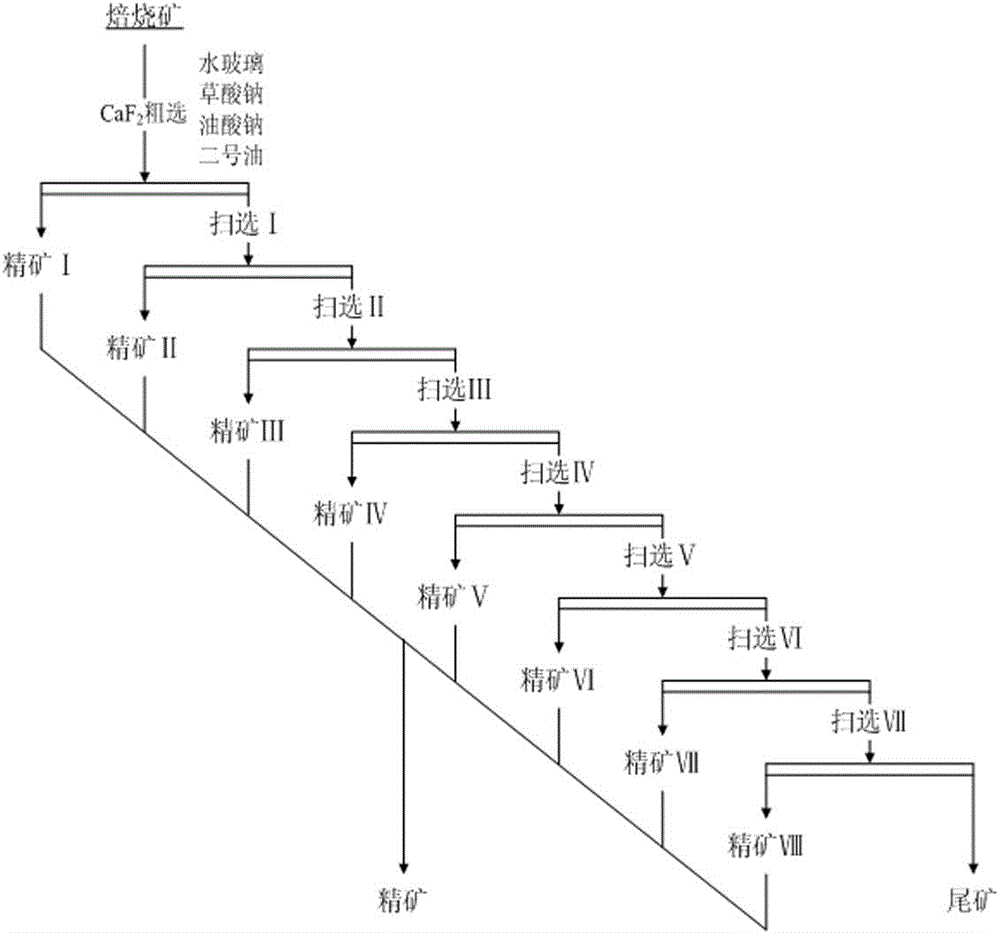

Calcium roasting floatation separation method for bastnaesite

ActiveCN104694736AHigh Calcium Fluoride ContentReduce consumptionFlotationResource utilizationRare earth

The invention belongs to the technical field of mineral processing, and relates to a calcium roasting floatation separation method for bastnaesite. The method comprises the following steps that firstly, bastnaesite and calcium hydroxide are mixed and roasted to obtain roasted ore; secondly, the roasted ore is placed in a floatation tank of a floatation machine, and water is added to form ore pulp; thirdly, water glass, oxalic acid or oxalate, sodium oleate and second oil are added in sequence and stirred, and roughing concentrate and roughing tailings are obtained through floatation; fourthly, the rouging tailings are scavenged in a five-nine level mode, and the calcium fluoride enrichment and the rare earth oxide are obtained. According to the method, the production procedure is shortened, meanwhile, consumption of reagent is reduced, resource utilization of valuable elements is achieved, the economic benefits are increased, and the environmental pollution is reduced.

Owner:NORTHEASTERN UNIV

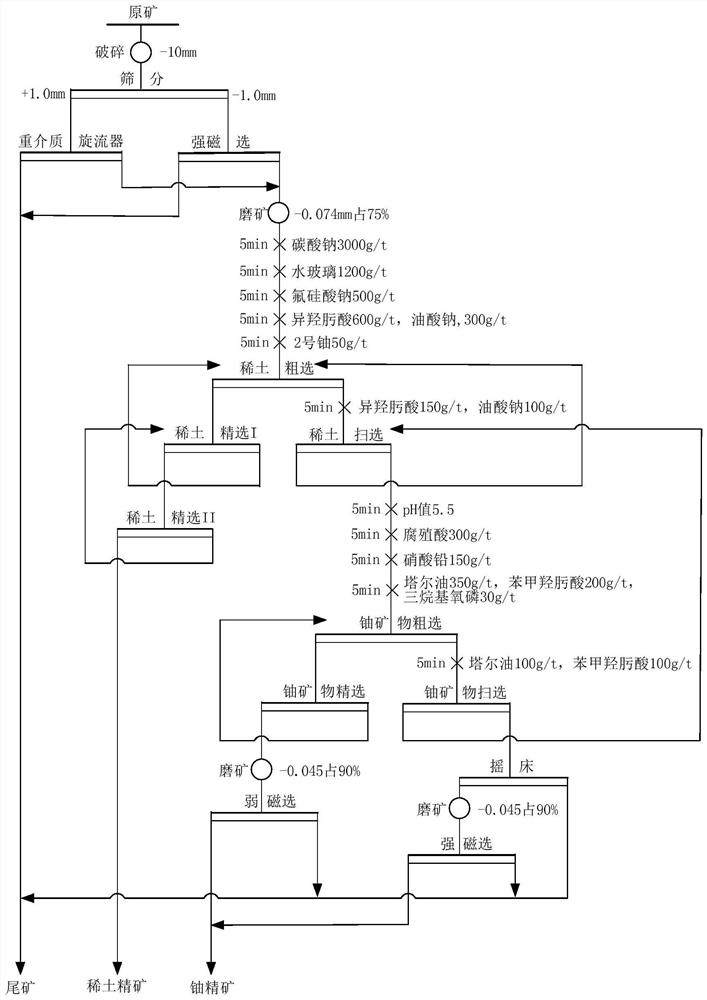

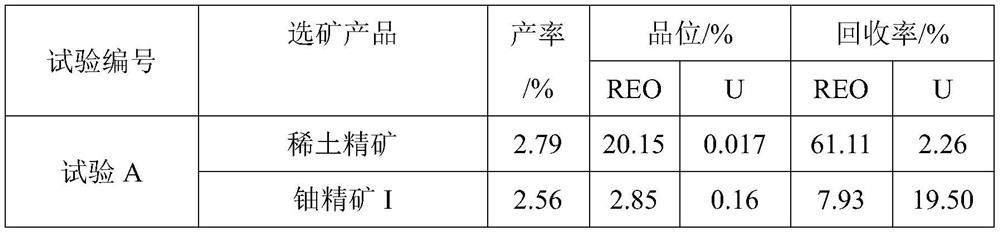

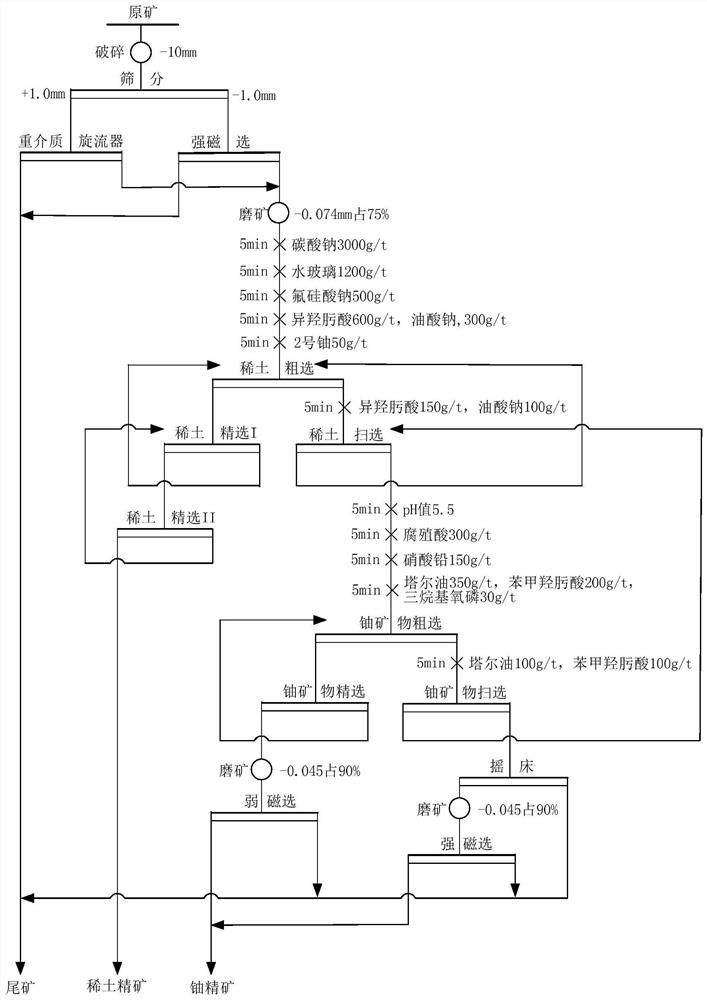

Beneficiation method for recovering uranium from rare earth ore

The invention discloses a beneficiation method for recovering uranium from rare earth ore. The beneficiation method comprises the steps that uranium-containing rare earth ore is finely crushed and then classified, and coarse-fraction ore and fine-fraction ore are pre-enriched through a dense medium cyclone and a high-intensity magnetic separator correspondingly; after the mixed rough concentrate is reground, rare earth minerals are firstly subjected to flotation, uranium minerals are then subjected to flotation, and after flotation uranium concentrate is reground, the uranium grade is further improved through weak magnetic iron removal; and after scavenging tailings in the flotation process are reground, uranium ore is further separated and enriched through reselection, the uranium concentrate subjected to reselection is subjected to strong magnetic separation, the uranium grade is improved, the yield of the finally obtained uranium concentrate is 5.50%, the uranium grade is 0.27%, and the recovery rate is 71.44%. According to the beneficiation method for recovering the uranium from rare earth ore, precious uranium resources can be efficiently recovered while rare earth ore recovery is not affected, and the radioactive hazard to the environment is reduced.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +1

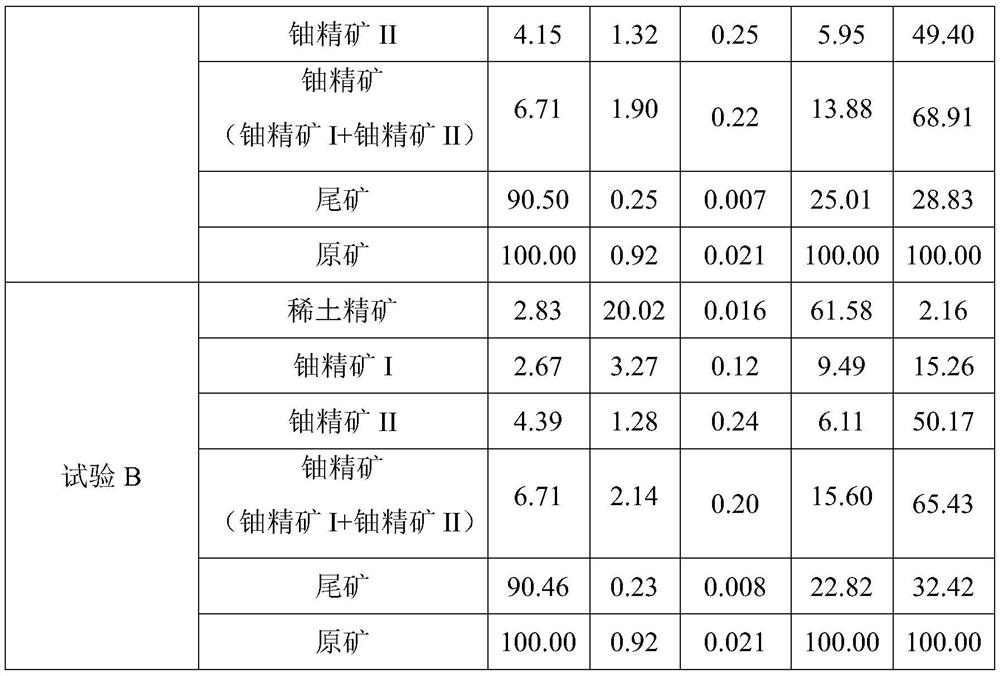

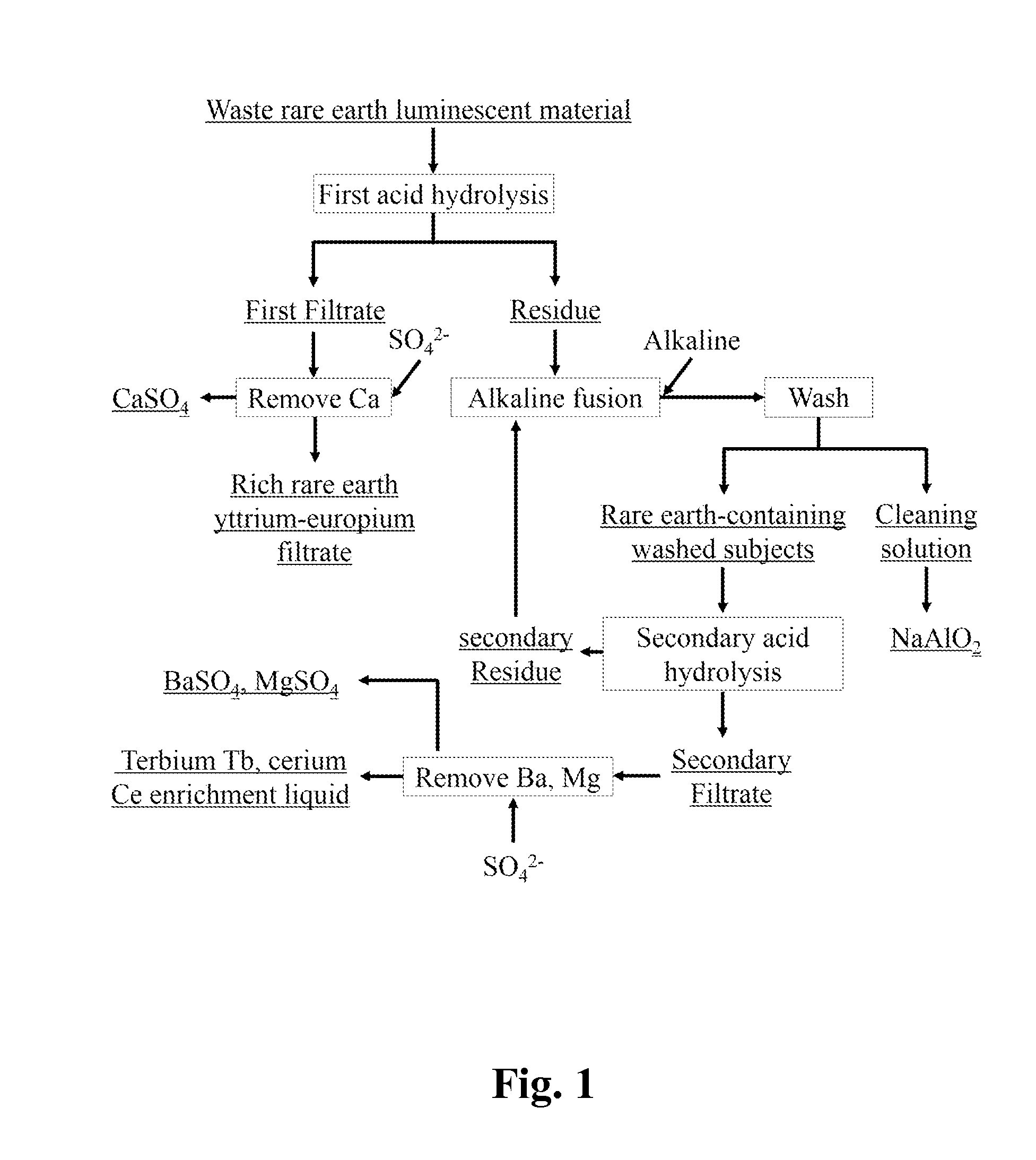

Method for recovering rare earth from waste rare earth luminescent material

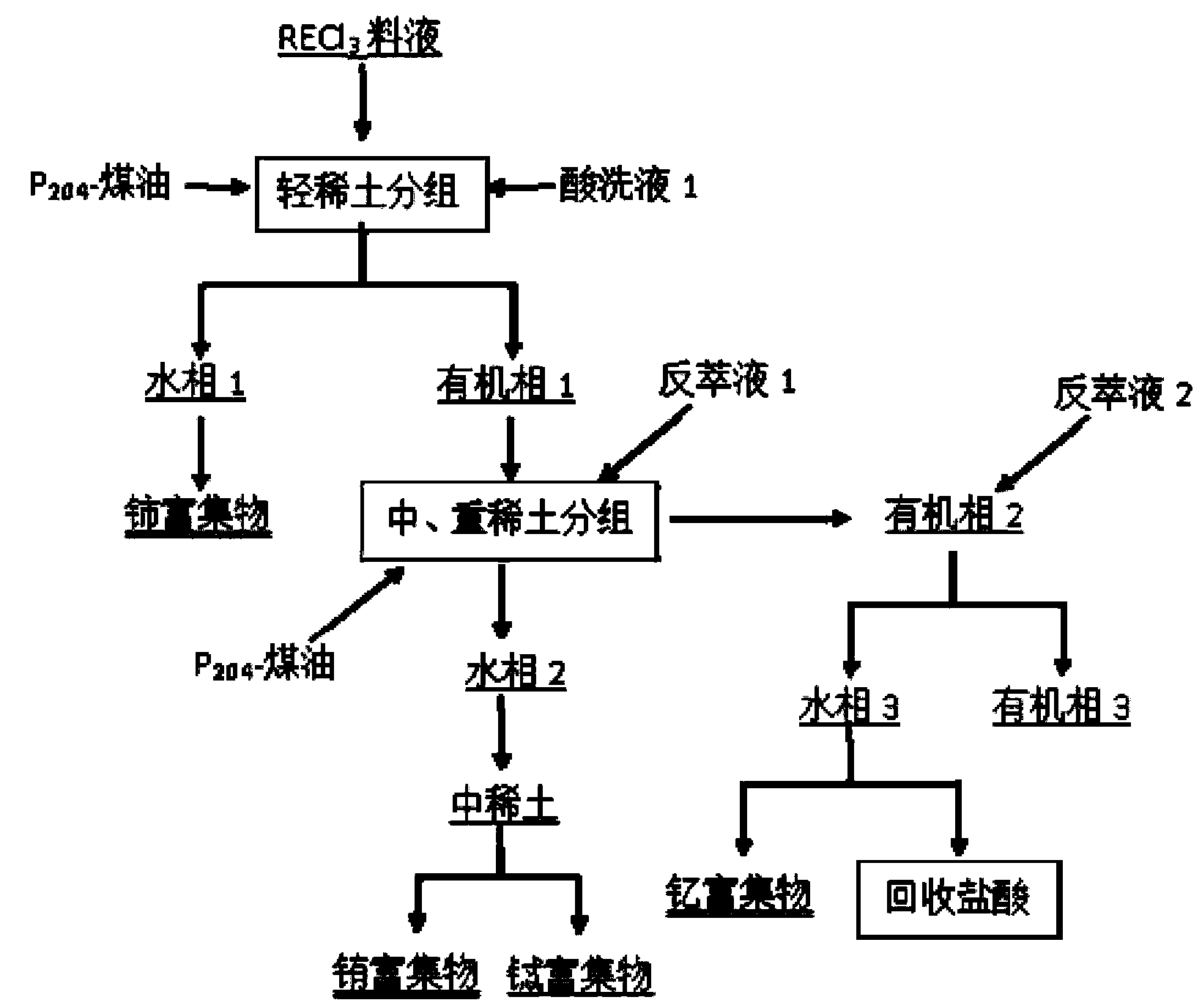

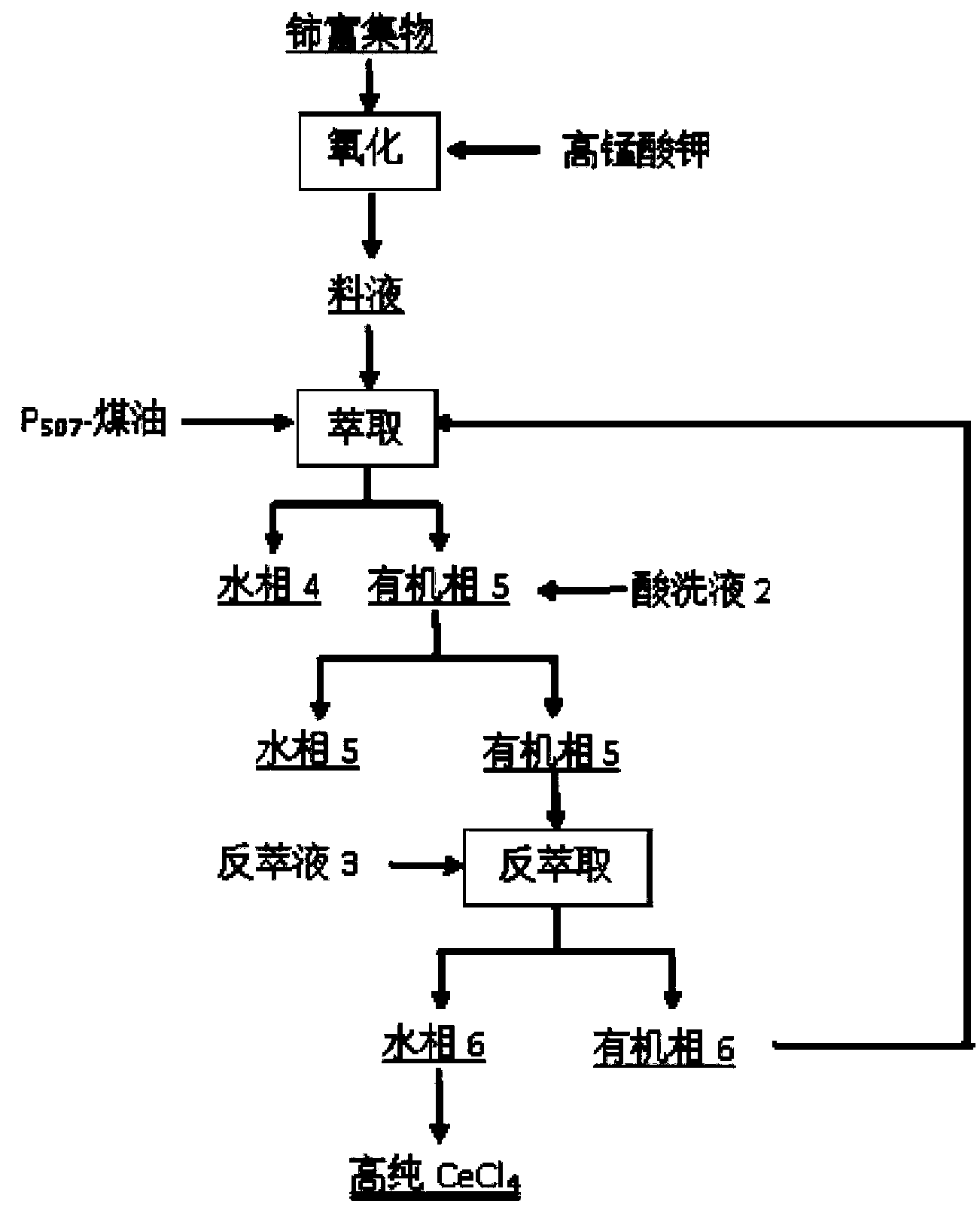

InactiveCN102660688BHigh recovery rateAvoid pollutionGlass recyclingCerium oxides/hydroxidesRare-earth elementAcid hydrolysis

A method for separating and recovering rare earths from waste rare earth luminescent materials. The process steps are: collection of waste rare earth luminescent materials, including rapid identification of rare earth fluorescent lamps and their dismantling and breaking, crushing of CRT displays, and stripping of waste rare earth luminescent materials from glass substrates and collection; pretreatment of waste rare earth luminescent materials, including demercury oxidation precipitation, alkali fusion and acid hydrolysis; extraction and separation of rare earth elements to obtain rare earth chloride enrichment; extraction and purification of rare earth elements to obtain high-purity rare earth chlorides; rare earth elements Precipitation and separation of rare earth oxalate or rare earth carbonate precipitates; rare earth oxalate or rare earth carbonate precipitates are roasted to obtain high-purity rare earth oxides. This method realizes the separation of rare earth elements Ce, Eu, Tb, Y and impurity elements such as Mg, Ba, Ca, and the complete separation and recovery of light, medium and heavy rare earth elements, and purifies to obtain high-purity rare earth oxides, so that resources are comprehensively recovered Utilization, the technological process is reasonable, economical and practical, the recovery rate of rare earth is high, and the added value of the product is high.

Owner:UNIV OF SCI & TECH BEIJING

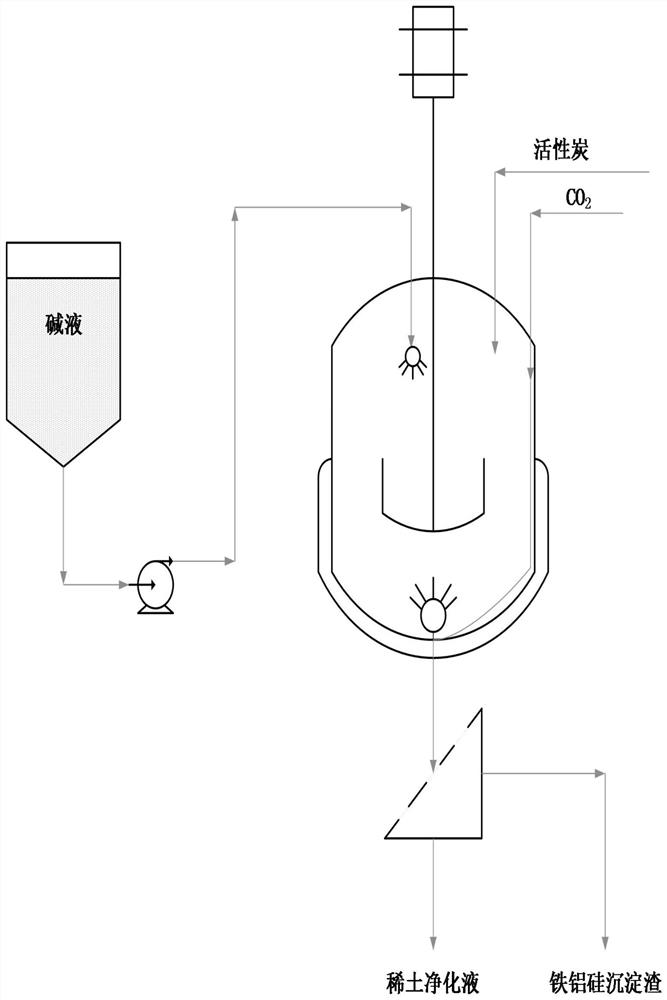

Impurity removal method for rare earth leaching solution

The invention belongs to the field of non-ferrous metallurgy, and relates to an impurity removal method for a rare earth leaching solution. The method comprises the following steps of under the condition of adding seed crystals, adding alkali liquor into the rare earth leaching solution by adopting an atomization charging mode, precipitating to remove iron, aluminum and silicon impurities, after the alkali liquor is completely added, blowing CO2, continuously reacting for a certain time, and filtering to obtain a rare earth leaching solution with low impurity content and impurity precipitation slag with low rear earth content. The method has the advantages of being simple in process, low in cost, high in impurity removal rate, good in precipitated slag filtering performance, low in slag rare earth content and the like, and has a good industrial application prospect.

Owner:JIANGXI UNIV OF SCI & TECH

A method for recovering rare earth from rare earth-containing wastewater

ActiveCN104878201BHigh recovery rate of rare earthReduce pollutionProcess efficiency improvementRare-earth elementHydrofluoric acid

The invention provides a method for recovering rare earth from rare earth-containing wastewater. The method comprises the following steps: 1, allowing the rare earth-containing wastewater to contact with an alkaline precipitating agent capable of precipitating rare earth metal elements, and carrying out solid-liquid separation after settlement to obtain a first solution and a rare earth precipitate; and 2, allowing the rare earth precipitate to contact with an aqueous solution containing hydrofluoric acid, and carrying out solid-liquid separation after settlement to obtain a second solution and rare earth fluoride. The method allows the rare earth metal elements to be effectively recovered, the recovery rate of the rare earth metal elements to be high and rare earth and fluoride in a raffinate obtained after recovery to reach environmental protection standard requirements, and the final raffinate subjected to an acid-base neutralization reaction is basically neutral and basically has no pollution to environment; and the rare earth fluoride obtained after recovery through the method is purified rare earth, can be used for molecular sieve modification, and can also be used in production of arc carbon rods and special steel alloys as an additive.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of crystalline rare-earth carbonate

InactiveCN104195332ALess rare earth lossHigh recovery rate of rare earthProcess efficiency improvementIonCarbonic acid

The invention relates to a preparation method of crystalline rare-earth carbonate. According to the scheme, the method comprises the following steps: selecting ion absorpt deposit and carrying out an in-situ leaching method, wherein the in-situ leaching method comprises the following steps: preparing a mixed leaching agent with the mass fraction being 2% by using two ammonium salts which are in a mass ratio of (1-4) to 1, adding an aluminum inhibitor which is 0.05% of mass of the mixed leaching agent, stirring evenly, and then carrying out in-situ leaching according to a liquid-solid ratio of (0.1-2) to 1; after the leaching solution completely seeps, adding top wash ore which is 10% of mass of the leaching agent, collecting the leaching solution, clarifying, and adding a precipitator, wherein the mass ratio of the precipitator to the leaching solution is (0.1-0.5) to 1; fully stirring for over 30 minutes, and standing and ageing for 6-24hours; filtering, washing sediment twice with clear water, filtering again, and baking at 110 DEG C, so as to obtain the crystalline rare-earth carbonate, wherein the recovery rate is 70-85%, and the purity is 90-95%. The crystalline rare-earth carbonate is prepared from easily available raw materials and is low in cost, high in recovery rate and high in product purity.

Owner:HUBEI POLYTECHNIC UNIV

Method for removing aluminum from rare-earth feed liquid

ActiveCN101979680BGood aluminum removal effectLow cost of aluminum removalProcess efficiency improvementRare-earth elementKerosene

The invention discloses a method for removing aluminum from rare-earth feed liquid, belongs to rare-earth feed liquid treatment technology and aims to provide the method for removing the aluminum from the rare-earth feed liquid, of which the aluminum-removing effect is good, the aluminum-removing cost is low, the rare-earth recovery rate is high, the operation and control are convenient, the process is simple and the investment in equipment is small. The key point of the technical scheme mainly comprises the following steps of: (1) preparing an organic phase from 15 to 25 volume percent of naphthenic acid and 15 to 25 volume percent of alcohol-kerosene; (2) adding the prepared organic phase and the rare-earth feed liquid into a stirring tank in a volume ratio of 2-5:1, starting the tank, stirring and uniformly mixing; (3) adding alkaline solution into the mixed liquid obtained in the step (2) with stirring, wherein the total number of moles of the added alkali is 50 to 100 percent of that of rare-earth elements in the rare-earth feed liquid; and (4) after adding the alkaline solution, continuously stirring for a certain time, stopping stirring and standing for a certain time, wherein the solution is separated into an aqueous phase and an organic phase and the aqueous phase is the rare-earth feed liquid from which the aluminum is removed. The method is applied to aluminum removal for the rare-earth feed liquid.

Owner:广东省富远稀土有限公司 +1

Process for extracting rare earth element by non-saponifiable phosphorous mixing extractant

ActiveCN100404706CResidual acid reductionStripping is easyProcess efficiency improvementRare-earth elementNitrate

The extraction and separation method for rare-earth element comprises: with rare-earth solution contained a plurality of rare-earth elements as material, preparing mixed extractant with the non-saponifiable P204 and one or two from P507, P229, P350, TBP, C272, C301, C302 and HEOPPA; in the mixed solution with rare-earth sulfate solution, or rare-earth sulfate and rare-earth chloride solution and rare-earth nitrate solution, extracting and separating rare-earth elements. This invention eliminates saponification to overcome pollution, reduces acidity to improve rare-earth concentration, and decreases the main material consumption more than 30% compared with the technique with NH4HCO3 and P507.

Owner:GRIREM ADVANCED MATERIALS CO LTD

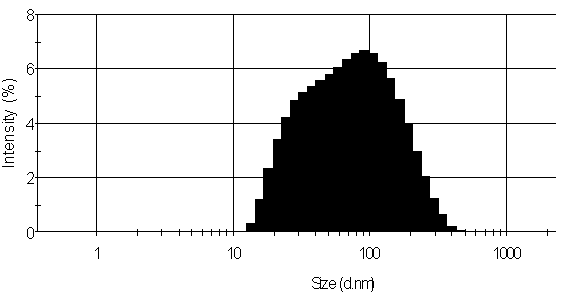

Method for recovering rare earth from low-concentration rare earth solution through prussian blue colloidal nanoparticles

InactiveCN102352448BSimple processLarge loading of rare earthWater/sewage treatment bu osmosis/dialysisProcess efficiency improvementDialysis membranesRare earth ions

The invention relates to a method for recovering rare earth from low-concentration rare earth solution through prussian blue colloidal nanoparticles (PB-CNP). The method comprises the following steps: firstly synthesizing a stable PB-CNP colloidal solution, loading into a bag produced by a dialysis membrane, enabling a dialysis bag containing PB-CNP suspension to be in contact with rare earth material liquid (the pH value is 4-7), and enabling rare earth ions to pass through membrane holes to be in contact with the PB-CNP for being adsorbed. Dilute acid solution is used for desorbing the rareearth from the PB-CNP suspension which absorbs the rare earth ions, thereby achieving the purpose of recovering the rare earth. The PB-CNP suspension and the rare earth material liquid can also be arranged in different channels on the two sides of the membrane of a membrane component for flowing in a countercurrent way, thereby achieving the high-efficient enrichment effect. The method has the advantages of simple process, large rare earth loading amount, high rare earth recovery rate and the like, and can be widely used for the rare earth material liquid of rare earth mines and separation factories; and furthermore, by adopting the method, the rare earth ions in low-concentration rare earth wastewater can be completed removed and recovered, thereby having wide application prospects.

Owner:NANCHANG UNIV

Preparation method of low-thorium lutetium oxide

ActiveCN101748275BEasy to separateThe separation effect is achievedRare earth metal compoundsProcess efficiency improvementLutetiumKerosene

The invention relates to a preparation method of low-thorium lutetium oxide, comprising the following steps of: firstly carrying out 3-10 level of primary countercurrent extraction on lutetium oxide extracted from a solvent as a raw material by adopting an isooctanol or kerosene solution of 0.5-2.0mol / L of N235 extracting agent, and then carrying out 3-10 level of countercurrent washing selectivebackextraction on organic phases of extracted thorium by adopting 0.1-2mol / L of alkali abluent solution; then separating the low-thorium lutetium oxide by a kerosene solution of 0.1-1.0mol / L of another extracting agent, carrying out 3-10 level of countercurrent washing selective backextraction on the organic phases of the extracted thorium by adopting 0.5-2mol / L of acidic abluent solution, carrying out oxalic precipitation, washing and dehydration on aqueous-phase lutetium oxide after thorium removal, and burning at the condition of 750-1000 DEG C to obtain a product, namely, the low-thorium lutetium oxide. In the method, rare earth and thorium are thoroughly separated, and the organic extracting agent is low in price.

Owner:江阴加华新材料资源有限公司

Decomposition method for rare earth ore concentrate

ActiveCN111334662ALess quantityAvoid it happening againProcess efficiency improvementMining engineeringExhaust fumes

The invention discloses a decomposition method for rare earth ore concentrate. The decomposition method comprises the following steps that the rare earth ore concentrate and 65%-85wt% of concentratedsulfuric acid are mixed in a reaction container, and then react at 150-185 DEG C to obtain a reaction product, wherein the dosage ratio between the rare earth ore concentrate and the concentrated sulfuric acid is 1kg: (7.8-9) L, and the reaction container is not a roasting device; the reaction product is subjected to solid-liquid separation treatment to obtain a first filter residue and a first filtrate; and the first filter residue is washed with water, and then is subjected to solid-liquid separation treatment to obtain a second filter residue and a second filtrate. According to the decomposition method, the generation of waste gas and waste residues is reduced while the high rare earth recovery rate can be kept.

Owner:BAOTOU RES INST OF RARE EARTHS

Carbonate deposition method of crystal type heavy rare earth

The invention relates to a method for precipitating crystal heavy-rare-earth carbonate, wherein pH of heavy-rare-earth chlorid solution is adjusted to 5.0 to 5.2 by the 8-10% carbon-ammonia water, adding polyacrylamide saturated-water solution in which the volume is 1-3 per thousand of that of heavy-rare-earth chlorid solution, filtering, and the filtrate is diluted to 0.4 to 0.5 M by water, adding eavy-rare-earth carbonate, as seed crystal, agitating to uniformly mix, then precipitating by 8-10% carbon-ammonia water, ending precipitating when pH is 6.2, adding water to 80-90% of volume of the precipitating container, stopping the press water for 12- 24 hours, washing the precipitate for 2 -3 times, filtrating, and crystal heavy-rare-earth carbonate is obtained. The invention has simple operation, low cost, high yield of heavy-rare-earth and good-quality product which contains low-water and low calcium carbonate, chloride ion or the like, is easy to filtrate, having convenient packaging, stacking and trasportation, and small contamination.

Owner:广东省富远稀土有限公司

A process for improving the recovery rate of rare earth and the grade of fluorite in tailings

InactiveCN103831173BHigh recovery rate of rare earthRaise the gradeFlotationRare earthMaterials science

The invention discloses a technique of improving rare earth recovery rate and fluorite grade in tailings, and the technique of improving rare earth recovery rate and fluorite grade in tailings comprise the following steps of : (1) mixing foam and mixing tailings are obtained through level one roughing, multistage of scavenging and multistage of refined selection of the tailings raw material; (2) total rare earth enrichment content and total fluorite enrichment content are obtained by separating the mixing foam; (3) rare earth concentrate is obtained through the level one roughing, multistage of scavenging and multistage of refined selection of the total rare earth enrichment content; (4) fluorite concentrate is obtained through the level one roughing, multistage of scavenging and multistage of refined selection of the total fluorite enrichment content. The technique of improving rare earth recovery rate and fluorite grade in tailings is capable of improving rare earth recovery rate and fluorite grade in tailings.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Method for preparing rare earth oxide powder by oxidizing and roasting rare earth mixture

PendingCN113979464AIncrease concentrationSolve pollutionRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentAir atmosphereNitrate salts

The invention relates to a method for preparing rare earth oxide powder by oxidizing and roasting a rare earth mixture, which comprises the following steps of: roasting the rare earth mixture containing rare earth chloride, nitrate or sulfate in an air atmosphere to obtain the rare earth oxide powder, wherein the roasting in the air atmosphere is divided into a first-stage roasting and a second-stage roasting, the first-stage roasting is to roast the rare earth mixture at 250-400 DEG C to obtain a precursor, the second-stage roasting is to roast the precursor by heating to 600-1200 DEG C, the air humidity is greater than 60%, and the rare earth oxide powder is obtained; the tail gas generated in the second-stage roasting is absorbed to obtain an inorganic acid by-product rare earth mixture. The method has the advantages of being simple in process, environmentally friendly, good in product performance and the like, and has a good industrial application prospect.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

A kind of recovery method of rare earth elements in NdFeB waste

InactiveCN104087755BHigh recovery rateImprove solubilityProcess efficiency improvementRecovery methodRare-earth element

The invention discloses a recovery method of rare earth elements in NdFeB (neodymium iron boron) waste materials, belonging to the technical field of recovering of rare earth resource. The recovery method comprises the following steps: (1) evenly mixing aluminum fluoride powder and cryolite powder according to the mass ratio of 1:1-1:10, to obtain a cryolite-aluminum fluoride mixture; (2) crushing the NdFeB waste materials into granules with granule size of 4-6mm and burying into the cryolite-aluminum fluoride mixture; (3); putting cryolite-aluminum fluoride mixture with buried NdFeB waste materials into an electric furnace and reacting for 3-12h at the temperature of 900-1200 DEG C; and (4) conducting solid-liquid separation to the product obtained after reaction to obtain solid residue and fused salt respectively, wherein the solid residue is waste steel, and the fused salt is a rare earth fluoride-cryolite-aluminum fluoride mixture. The unoxidized rare earth elements in the NdFeB waste materials can be selectively extracted through aluminum fluoride, rare earth oxidized into oxides can be better dissolved by cryolite, and therefore the recovery rate of rare earth can be greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for Treating Waste Rare Earth Luminescent Material Using Dual Hydrochloric Acid Dissolution

InactiveUS20150225813A1Improve decomposition rateSimple separation and enrichmentRare earth metal compoundsProcess efficiency improvementSodium aluminateRare earth

The invention belongs to the field of recycling of resources, in particular to a method for waste rare earth luminescent material by dual hydrochloric acid. First hydrochloric acid was used to dissolve the red phosphor powder (Y2O3:Eu) priority, and yttrium-rich rare earth chloride solution and residue were obtained after filtered. Residue's major components were green and blue phosphor powder, and the removal of Ca2+ in filtrate was conducted by using Na2SO4, and CaSO4 precipitation separation was conducted to get rich rare earth chloride solution, europium and yttrium. Residue was mixed with alkali to perform alkaline fusion at high temperature to decompose green and blue powder, then sodium aluminate, magnesium, barium and rare earth oxides were obtained. Alkaline fusion products were washed with water, and filtered, and then sodium aluminate solution and residues containing rare earth oxides were obtained.

Owner:UNIV OF SCI & TECH BEIJING

Process method for recovering rare earth from cerium oxide waste material

InactiveCN106148710AReduce lossesSimple processing methodProcess efficiency improvementRare-earth elementPregnant leach solution

The invention relates to a process method for recovering rare earth from a cerium oxide waste material. The process method is characterized in that the cerium oxide waste material with 70-85wt% of REO is screened through a sieve with the mesh being 100 to remove solid impurities such as weeds and crushed stones, 1-1.4 times the theoretical amount of sulfuric acid and not less than 1-1.4 times the theoretical amount of FeSO4 are added, and a mixture is heated to 45 DEG C to 55 DEG C under continuous stirring; then leaching is conducted for 1 h to 1.5 h, solid-liquid separation is conducted, and a primary leaching solution is obtained; and the primary leaching solution is neutralized with MgO and subjected to impurity removal, then secondary solid-liquid separation is conducted, and a secondary leaching solution is obtained. The process method has the beneficial effects that the process method is simple and feasible, capable of being used easily on a large scale and high in rare earth recovery rate, and the recovery rate of the rare earth element in the secondary leaching solution is higher than 80%.

Owner:BAOTOU HUAMEI RE PRODS

A kind of beneficiation method for recovering uranium from rare earth ore

ActiveCN113333155BEfficient recyclingReduce Radiation HazardsSolid separationUranium oreMagnetic separator

The invention discloses a beneficiation method for recovering uranium from rare earth ores. In the method, the uranium-containing rare earth ore is finely crushed and then classified, and the coarse-grained ore and fine-grained ore are pre-concentrated by a heavy medium cyclone and a strong magnetic separator respectively; Select rare earth minerals, then flotation uranium minerals, flotation uranium concentrates are regrind to further improve the uranium grade through weak magnetic iron removal; the scavenging tailings in the flotation process are regrind and then the uranium minerals are further separated and enriched by gravity separation, Gravity-separated uranium concentrate is then subjected to strong magnetic separation to improve the uranium grade. The final uranium concentrate has a rate of 5.50%, a uranium grade of 0.27%, and a recovery rate of 71.44%. This method can efficiently recover valuable rare earth ore without affecting the recovery. Uranium resources, reduce the radioactive harm to the environment.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +1

Method for extracting and recovering rare earth with low-concentration rare earth solution

ActiveCN104294063BEfficient Clean ExtractionImprove resource utilizationProcess efficiency improvementHigh concentrationRare earth

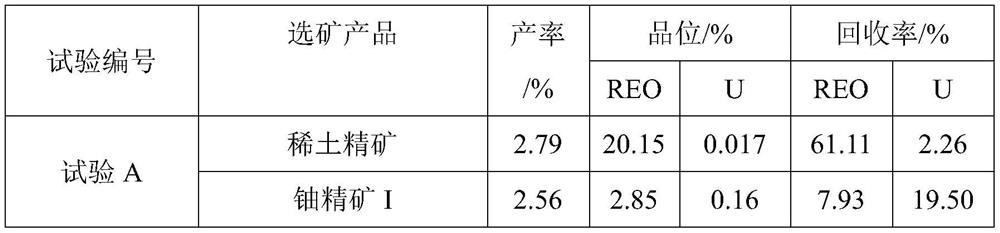

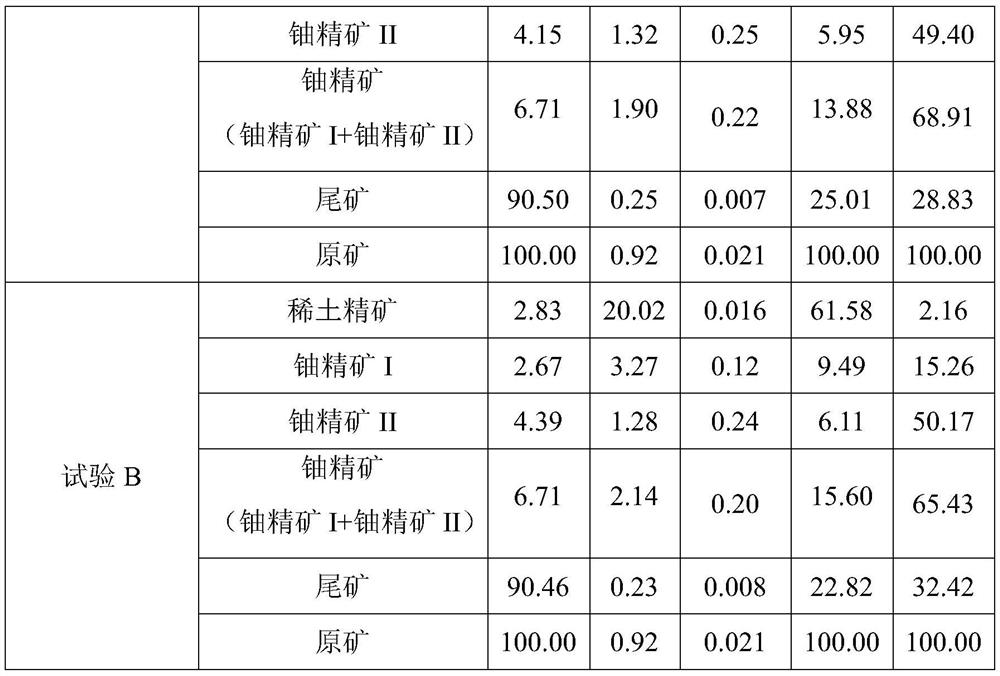

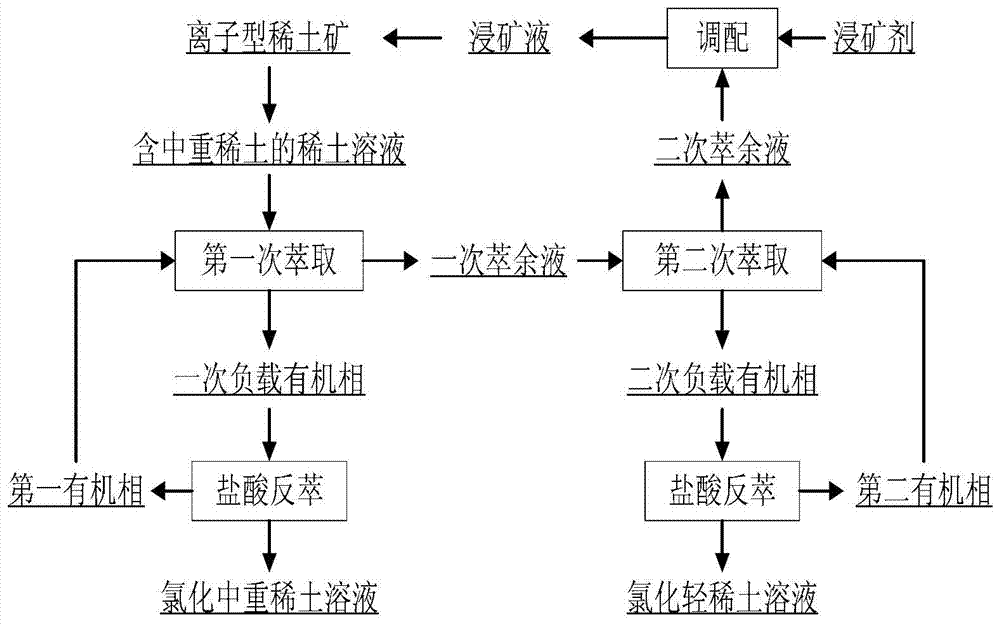

The invention discloses a method for recovery of rare earth by low concentration rare earth solution extraction. The method uses a rare earth solution containing heavy and middle rare earth as raw material liquid, and comprises the following steps: subjecting the raw material liquid to a first extraction by using a first organic phase of an acidic phosphorous extractant with PKa value higher than 4, so as to obtain a first loading organic phase and a first raffinate; subjecting the first raffinate to a second extraction by using a second organic phase of an acidic phosphorous extractant with PKa value less than 3.5, o as to obtain a second loading organic phase and a second raffinate; and conducting reverse extraction to recover the rare earth in the first loading organic phase and the second loading organic phase, so as to obtain high concentration chlorination rare earth solution. The method for recovery of rare earth by low concentration rare earth solution extraction has the advantages of shortened process flow, improved rare earth recovery, reduced production cost and no emission of ammonia nitrogen wastewater, realizes clean and efficient extraction of low concentration rare earth solution, improves the utilization of rare earth resources, reduces pollutant emission and chemical raw material consumption, and effectively protect the environment.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com