Impurity removal method for rare earth leaching solution

A leachate and rare earth technology, applied in the field of impurities, can solve the problems of poor removal of iron and silicon, failure to meet production requirements, and stay in the research stage, etc., to reduce liquid-solid separation time, improve separation selectivity, and reduce rare earth The effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

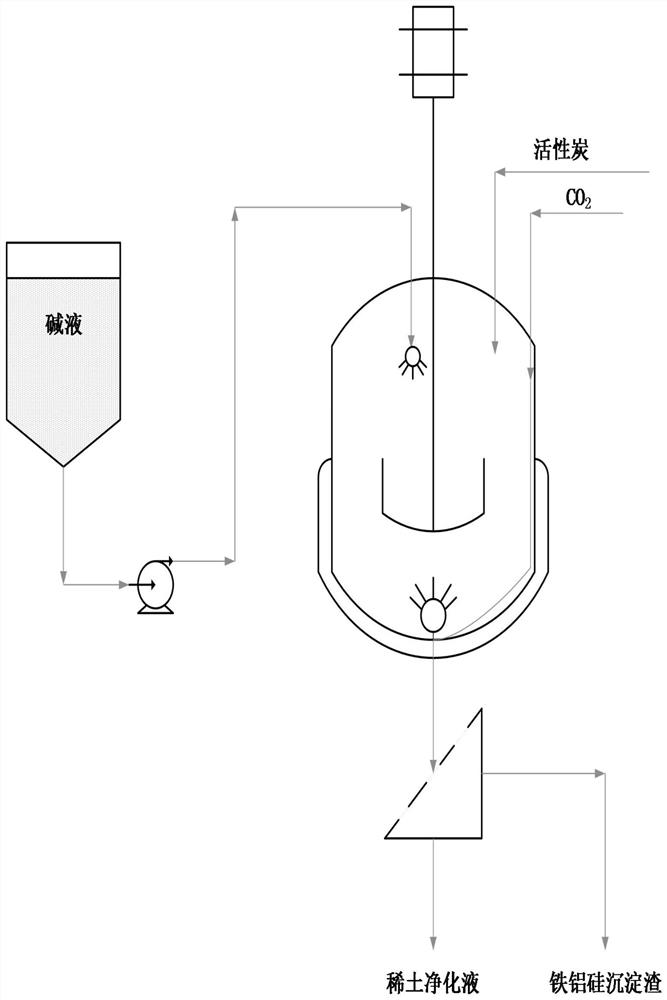

Embodiment 1

[0050] Add 8m to the reactor 3 In the rare earth leaching solution (Fe:865mg / L, Al:1425mg / L, Si:177mg / L, pH:1.5), add 4kg activated carbon powder, open high-speed shear mixer, stirring speed is 3500rpm, then in the reactor with Add 3M ammonia solution by atomization, the feeding speed is 0.2m 3 / h. When the pH of the leachate rises to 5.2, continue to stir for 45 minutes, and control the pH at the end of the reaction to be 5.2; then feed 60% CO into the reactor. 2 Gas, the gas flow rate is 3.2m 3 / h, after continuing to react for 4h, the reaction can be terminated, and after liquid-solid separation, precipitation slag and rare earth purification solution are obtained, wherein the content of rare earth (rare earth total amount) in the precipitation slag (by dry weight) is 0.34% (weight). , the contents of iron, aluminum, and silicon in the rare earth purification solution are 3.7, 247.5, and 34.5 mg / L, respectively.

Embodiment 2

[0059] Add 8m to the reactor 3 In the rare earth leaching solution (Fe: 1308mg / L, Al: 907mg / L, Si: 204mg / L, pH: 1.2), add 5kg activated carbon powder, open the high-speed shear mixer, stirring speed is 5000rpm, then in the reaction kettle with Add 2.8M ammonium bicarbonate solution by atomization, the feeding speed is 0.35m 3 / h. When the pH of the leaching solution rises to 5.1, continue to stir for 80 minutes to control the pH at the end of the reaction to 5.1; then feed 75% CO into the reaction kettle. 2 Gas, the gas flow rate is 4.5m 3 / h, after continuing to react for 5h, the reaction can be terminated. After liquid-solid separation, precipitation slag and rare earth purification solution are obtained, wherein the rare earth content in the precipitation slag is 0.41%, and iron, aluminum, and silicon content in the rare earth purification solution are respectively 3.1, 285.7, 32.7mg / L.

Embodiment 3

[0065] Add 8m to the reactor 3 In the rare earth leaching solution (Fe:865mg / L, Al:1425mg / L, Si:177mg / L, pH:1.5), add 2kg activated carbon powder, open the high-speed shear mixer, stirring speed is 4000rpm, then in the reactor with Add 2.2M NaOH solution by atomization, the feeding speed is 0.12m 3 / h. When the pH of the leaching solution rises to 5.1, continue to stir for 60 minutes to control the pH at the end of the reaction to 5.1; then feed 90% CO into the reaction kettle 2 Gas, the gas flow rate is 5m 3 / h, after continuing to react for 3h, the reaction can be terminated. After liquid-solid separation, precipitation slag and rare earth purification solution are obtained, wherein the rare earth content in the precipitation slag is 0.44%, and the iron, aluminum and silicon contents in the rare earth purification solution are respectively 4.4, 266.4, 36.7mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com