Method for extracting and recovering rare earth with low-concentration rare earth solution

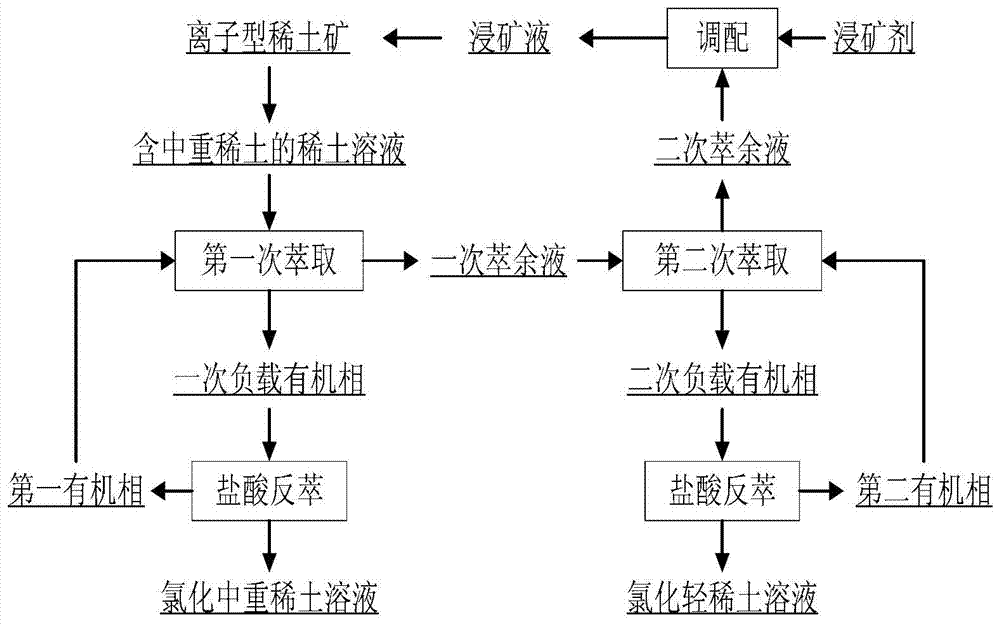

A rare earth solution, low concentration technology, applied in the direction of improving process efficiency, etc., can solve the problems of low rare earth recovery rate, high cost, easy to pollute the environment, etc., to achieve the effect of improving rare earth recovery rate, protecting the environment and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Magnesium sulfate is used as the leaching agent to leach ion-adsorbed rare earth ores to obtain a rare earth sulfate solution containing rare earth REO 0.12g / L as a raw material solution (wherein REO / TREO is 50% for medium and heavy rare earths, and REO / TREO for light rare earths is 50%) %).

[0044] Use 0.5mol / L P507-containing first organic phase (the diluent is kerosene) to extract the medium-heavy rare earths in the raw material liquid, using two-stage cross-flow extraction, the volume ratio of the first organic phase to the aqueous phase (O / A) is 1:25, the extraction rate of medium and heavy rare earths in the raw material solution was 80.3%, and the primary loaded organic phase and primary raffinate containing rare earth REO3.9g / L were obtained.

[0045] The primary raffinate was then extracted with 0.5 mol / L of P204-containing second organic phase (the diluent is kerosene) to extract the remaining rare earths, using 4-stage cross-flow extraction, the volume ratio...

Embodiment 2

[0050] The mixed solution of magnesium sulfate and magnesium chloride is used as the leaching agent to leach ion-adsorbed rare earth ores, and a rare earth solution containing 0.5g / L of rare earth REO is obtained as a raw material solution (the medium and heavy rare earth REO / TREO is 30%, and the light rare earth REO / TREO is 70%).

[0051] Use 0.70 mol / L of the first organic phase containing P507 (the diluent is sulfonated kerosene) to extract the medium and heavy rare earths in the raw material liquid, and use 3-stage semi-countercurrent extraction, the volume ratio of the organic phase to the aqueous phase (O / A) is 1:20, the extraction rate of medium and heavy rare earths in the raw material liquid is 90.5%, and the primary loaded organic phase and primary raffinate containing rare earth REO4.0g / L are obtained.

[0052] The primary raffinate is then extracted with 0.8 mol / L of P204-containing second organic phase (the diluent is n-hexane) to extract the remaining rare earth...

Embodiment 3

[0057] Magnesium sulfate solution is used as the leaching agent to leach ion-adsorbed rare earth ores to obtain a rare earth sulfate solution containing rare earth REO1. 80%).

[0058] Use 1.2mol / L P229-containing first organic phase (the diluent is kerosene) to extract the medium-heavy rare earths in the raw material liquid, adopt 4-stage countercurrent extraction, and the volume ratio of organic phase to aqueous phase (O / A) is 1:10 , the extraction rate of medium and heavy rare earths in the raw material solution was 82%, and a primary loaded organic phase and primary raffinate containing rare earth REO3.0g / L were obtained.

[0059] The primary raffinate is then extracted with 1.0 mol / L of the second organic phase containing P204 (the diluent is kerosene) to extract the remaining rare earths, using 3-stage countercurrent extraction, and the volume ratio (O / A) of the organic phase to the aqueous phase is 1: 10. Obtain a secondary loaded organic phase containing rare earth RE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com