Method for cleanly and efficiently extracting rare earth elements from waste fluorescent powder

A rare earth element and phosphor technology, which is applied in the field of clean and efficient extraction of rare earth elements, can solve the problems of low comprehensive recovery rate of rare earth, incomplete decomposition of phosphor powder, complicated production process, etc., so as to reduce the reaction activation energy and improve the leaching rate of rare earth. , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

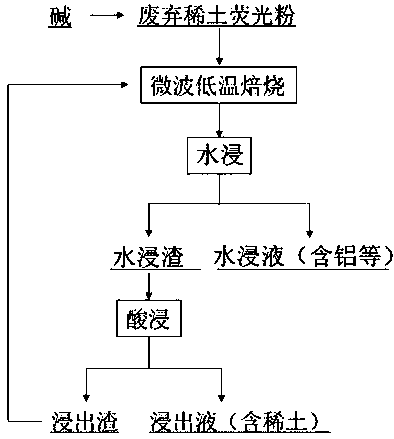

[0025] Such as figure 1 As shown, the method for cleanly and efficiently extracting rare earth elements from waste phosphor powder comprises the following steps:

[0026] The first step, the mixing of the base:

[0027] Take 10g of waste phosphor powder (waste phosphor powder includes green powder, blue powder or their mixture; waste phosphor powder mainly includes the following rare earth elements (Eu 2 o 3 0.1wt%, Tb 4 o 7 8wt%, CeO 2 5wt%) and alkali (sodium hydroxide) in a mass ratio of 1:10 to obtain a mixture;

[0028] The second step, microwave low-temperature roasting:

[0029] The mixture obtained in the first step is fired at a microwave power of 5kW and heated to a temperature of 500°C for 1 hour at a low temperature to obtain a roasted material;

[0030] The third step, water immersion to remove impurities:

[0031] Grind the calcined material obtained in the second step into powder, then add an aqueous solution according to the liquid-solid ratio of 6:1ml / ...

Embodiment 2

[0037] Such as figure 1 As shown, the method for cleanly and efficiently extracting rare earth elements from waste phosphor powder comprises the following steps:

[0038] The first step, the mixing of the base:

[0039] Take 10g of waste phosphor powder (waste phosphor powder includes green powder, blue powder or their mixture; waste phosphor powder mainly includes the following rare earth element Eu 2 o 3 4wt%, Tb 4 o 7 1wt%, CeO 2 1wt%) and alkali (sodium peroxide) in a mass ratio of 1:1 to obtain a mixture;

[0040] The second step, microwave low-temperature roasting:

[0041] The mixture obtained in the first step is fired at a microwave power of 1kW and heated to a temperature of 300°C for 0.5h at a low temperature to obtain a roasted material;

[0042] The third step, water immersion to remove impurities:

[0043] Grind the calcined material obtained in the second step into powder, then add an aqueous solution according to the liquid-solid ratio of 1:1ml / g, soak ...

Embodiment 3

[0049] Such as figure 1 As shown, the method for cleanly and efficiently extracting rare earth elements from waste phosphor powder comprises the following steps:

[0050] The first step, the mixing of the base:

[0051] Take 10g of waste phosphor powder (waste phosphor powder includes green powder, blue powder or their mixture; waste phosphor powder mainly includes the following rare earth element Eu 2 o 3 2wt%, Tb 4 o 7 5wt%, CeO 2 10wt%) and alkali (sodium hydroxide and sodium carbonate with a mass ratio of 1:1) are uniformly mixed in a mass ratio of 1:5 to obtain a mixture;

[0052] The second step, microwave low-temperature roasting:

[0053] The mixture obtained in the first step was roasted at a low temperature of 800° C. for 0.8 h at a microwave power of 3 kW to obtain a roasted material;

[0054] The third step, water immersion to remove impurities:

[0055]Grind the calcined material obtained in the second step into powder, then add an aqueous solution accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com